图形符号:

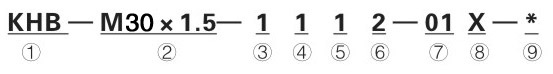

KHB系列高压球阀型号说明:

① 系列代号:KHB(BKH)系列、KHM(MKH)系列

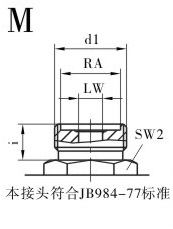

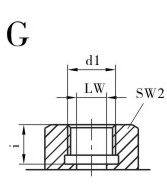

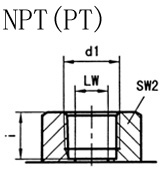

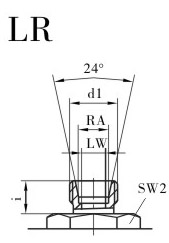

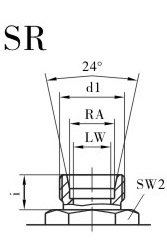

② 连接代号:M** 、G** 、 **LR 、**SR、PT**、NPT**

③ 阀体材料:1-钢、2-不锈钢

④ 球体材料:1-钢、2-黄铜、3-不锈钢

⑤ 工作温度:1、-25~+100℃ 2、-30~+170℃

⑥ 其他密封:2-丁腈橡胶、4-氟橡胶

⑦ 手柄形式:01-铝质直柄02-铝质曲柄03-铸锌直柄04-铸锌曲柄05-钢质直柄06-钢质曲柄09-不带手柄

⑧ 设计序号:由生产商定

⑨ 表面处理:空白-磷化、G-电镀黄锌

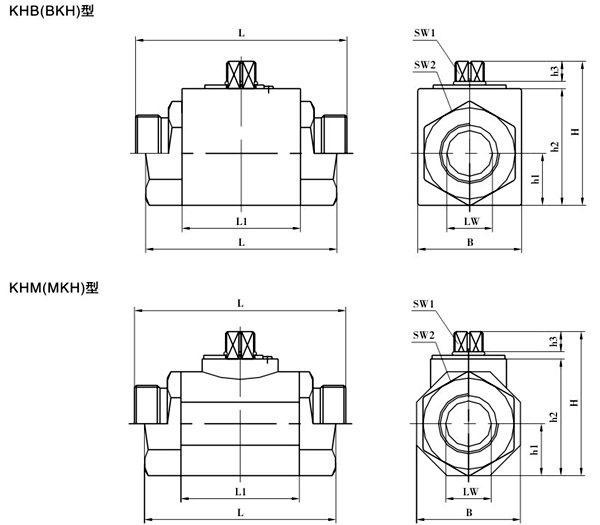

KHB系列高压球阀外形尺寸:

KHB系列高压球阀尺寸表:

连接口略图:

| 简略型号 | PN(bar) | DN | LW | RA | d1 | i | L | L1 | B | H | h1 | h2 | h3 | SW1 | SW2 |

| KHB-M16×1.5 | 500 | 06 | 06 | 11 | M16×1.5 | 11 | 69 | 40 | 26 | 45 | 13.5 | 33 | 8 | 09 | 22 |

| KHB-M22×1.5 | 500 | 08 | 08 | 16 | M22×1.5 | 12 | 76 | 42 | 32 | 49 | 16 | 36 | 10 | 09 | 27 |

| KHB-M27×1.5 | 500 | 10 | 10 | 20 | M27×1.5 | 12 | 76 | 42 | 32 | 49 | 16 | 36 | 10 | 09 | 27 |

| KHB-M30×1.5 | 400 | 16 | 15 | 24 | M30×1.5 | 13 | 84 | 48 | 38 | 61 | 19 | 45 | 11 | 09 | 32 |

| KHB-M36×2 | 315 | 20 | 20 | 30 | M36×2 | 15 | 103 | 60 | 48 | 70 | 25 | 55 | 11 | 12 | 41 |

| KHB-M42×2 | 315 | 25 | 23 | 35 | M42×2 | 18 | 116 | 65 | 57 | 79 | 28.5 | 64 | 11 | 12 | 50 |

| KHB-M52×2 | 315 | 32 | 32 | 40 | M52×2 | 20 | 149 | 84 | 75 | 101 | 37.5 | 84 | 12 | 14 | 60 |

| KHB-M60×2 | 315 | 40 | 38 | 45 | M60×2 | 22 | 174 | 91 | 85 | 112 | 42.5 | 95 | 12 | 14 | 70 |

| 简略型号 | PN(bar) | DN | LW | RA | d1 | i | L | L1 | B | H | h1 | h2 | h3 | SW1 | SW2 |

| KHB-G1/8 | 500 | 04 | 06 | / | G1/8 | 10 | 69 | 40 | 26 | 45 | 13.5 | 33 | 8 | 09 | 22 |

| KHB-G1/4 | 500 | 06 | 06 | / | G1/4 | 14 | 69 | 40 | 26 | 45 | 13.5 | 33 | 8 | 09 | 22 |

| KHB-G3/8 | 500 | 10 | 10 | / | G3/8 | 14 | 72 | 42 | 32 | 49 | 16 | 36 | 10 | 09 | 27 |

| KHB-G1/2 | 500 | 13 | 12 | / | G1/2 | 16 | 83 | 48 | 35 | 49 | 17 | 40 | 10 | 09 | 30 |

| KHB-G1/2 | 400 | 16 | 15 | / | G1/2 | 16 | 83 | 48 | 38 | 61 | 19 | 45 | 11 | 09 | 32 |

| KHB-G3/4 | 315 | 20 | 20 | / | G3/4 | 18 | 95 | 60 | 48 | 70 | 25 | 55 | 11 | 12 | 41 |

| KHB-G1 | 315 | 25 | 25 | / | G1 | 21 | 113 | 65 | 57 | 79 | 28.5 | 64 | 11 | 12 | 50 |

| KHB-G 11/4 | 315 | 32 | 32 | / | G 11/4 | 22 | 110 | 84 | 75 | 101 | 37.5 | 84 | 12 | 14 | 60 |

| KHB-G 11/2 | 315 | 40 | 38 | / | G 11/2 | 24 | 130 | 91 | 85 | 112 | 42.5 | 95 | 12 | 14 | 70 |

| KHB-G2 | 315 | 50 | 48 | / | G2 | 26 | 140 | 100 | 105 | 131 | 52.5 | 112 | 12 | 14 | 80 |

| 简略型号 | PN(bar) | DN | LW | RA | d1 | i | L | L1 | B | H | h1 | h2 | h3 | SW1 | SW2 |

| KHB-NPT1/8 | 500 | 04 | 06 | / | NPT1/8 | 10 | 69 | 40 | 26 | 45 | 13.5 | 33 | 8 | 09 | 22 |

| KHB-NPT1/4 | 500 | 06 | 06 | / | NPT1/4 | 14 | 69 | 40 | 26 | 45 | 13.5 | 33 | 8 | 09 | 22 |

| KHB-NPT3/8 | 500 | 10 | 10 | / | NPT3/8 | 14 | 72 | 42 | 32 | 49 | 16 | 36 | 10 | 09 | 27 |

| KHB-NPT1/2 | 500 | 13 | 12 | / | NPT1/2 | 16 | 83 | 48 | 35 | 49 | 17 | 40 | 10 | 09 | 30 |

| KHB-NPT1/2 | 400 | 16 | 15 | / | NPT1/2 | 16 | 83 | 48 | 38 | 61 | 19 | 45 | 11 | 09 | 32 |

| KHB-NPT3/4 | 315 | 20 | 20 | / | NPT3/4 | 18 | 95 | 60 | 48 | 70 | 25 | 55 | 11 | 12 | 41 |

| KHB-NPT1 | 315 | 25 | 25 | / | NPT1 | 21 | 113 | 65 | 57 | 79 | 28.5 | 64 | 11 | 12 | 50 |

| KHB-NPT 11/4 | 315 | 32 | 32 | / | NPT 11/4 | 22 | 110 | 84 | 75 | 101 | 37.5 | 84 | 12 | 14 | 60 |

| KHB-NPT 11/2 | 315 | 40 | 38 | / | NPT 11/2 | 24 | 130 | 91 | 85 | 112 | 42.5 | 95 | 12 | 14 | 70 |

| KHB-NPT2 | 315 | 50 | 48 | / | NPT2 | 26 | 140 | 100 | 105 | 131 | 52.5 | 112 | 12 | 14 | 80 |

| 简略型号 | PN(bar) | DN | LW | RA | d1 | i | L | L1 | B | H | h1 | h2 | h3 | SW1 | SW2 |

| KHB-06LR | 500 | 04 | 04 | 06 | M12×1.5 | 10 | 67 | 40 | 26 | 45 | 13.5 | 33 | 8 | 09 | 22 |

| KHB-08LR | 500 | 06 | 06 | 08 | M14×1.5 | 10 | 67 | 40 | 26 | 45 | 13.5 | 33 | 8 | 09 | 22 |

| KHB-10LR | 500 | 08 | 08 | 10 | M16×1.5 | 11 | 74 | 42 | 32 | 49 | 16 | 36 | 10 | 09 | 27 |

| KHB-12LR | 500 | 10 | 10 | 12 | M18×1.5 | 11 | 74 | 42 | 32 | 49 | 16 | 36 | 10 | 09 | 27 |

| KHB-15LR | 500 | 13 | 12 | 15 | M22×1.5 | 12 | 82 | 48 | 35 | 53 | 17 | 40 | 10 | 09 | 30 |

| KHB-15LR | 500 | 12 | 12 | 15 | M22×1.5 | 12 | 82 | 48 | 38 | 61 | 19 | 45 | 11 | 09 | 32 |

| KHB-18LR | 500 | 13 | 12 | 18 | M26×1.5 | 12 | 82 | 48 | 35 | 53 | 17 | 40 | 10 | 09 | 30 |

| KHB-18LR | 400 | 16 | 15 | 18 | M26×1.5 | 12 | 82 | 48 | 38 | 61 | 19 | 45 | 11 | 09 | 32 |

| KHB-22LR | 315 | 20 | 19 | 22 | M30×2 | 14 | 101 | 60 | 48 | 70 | 25 | 55 | 11 | 12 | 41 |

| KHB-28LR | 315 | 25 | 24 | 28 | M36×2 | 14 | 108 | 65 | 57 | 79 | 28.5 | 64 | 11 | 12 | 50 |

| KHB-35LR | 315 | 32 | 30 | 35 | M45×2 | 16 | 141 | 84 | 75 | 101 | 37.5 | 84 | 12 | 14 | 60 |

| KHB-42LR | 315 | 40 | 36 | 42 | M52×2 | 16 | 162 | 91 | 85 | 112 | 42.5 | 95 | 12 | 14 | 70 |

| 简略型号 | PN(bar) | DN | LW | RA | d1 | i | L | L1 | B | H | h1 | h2 | h3 | SW1 | SW2 |

| KHB-08SR | 500 | 04 | 05 | 08 | M16×1.5 | 12 | 73 | 40 | 26 | 45 | 13.5 | 33 | 8 | 09 | 22 |

| KHB-10SR | 500 | 06 | 06 | 10 | M18×1.5 | 12 | 73 | 40 | 26 | 45 | 13.5 | 33 | 8 | 09 | 22 |

| KHB-12SR | 500 | 08 | 08 | 12 | M20×1.5 | 12 | 76 | 42 | 32 | 49 | 16 | 36 | 10 | 09 | 27 |

| KHB-14SR | 500 | 10 | 10 | 14 | M22×1.5 | 14 | 80 | 42 | 32 | 49 | 16 | 36 | 10 | 09 | 27 |

| KHB-16SR | 500 | 13 | 12 | 16 | M24×1.5 | 14 | 86 | 48 | 35 | 53 | 17 | 40 | 10 | 09 | 30 |

| KHB-16SR | 500 | 12 | 12 | 16 | M24×1.5 | 14 | 86 | 48 | 38 | 61 | 19 | 45 | 11 | 09 | 32 |

| KHB-20SR | 500 | 13 | 12 | 20 | M30×2 | 16 | 90 | 48 | 35 | 53 | 17 | 40 | 10 | 09 | 30 |

| KHB-20SR | 400 | 16 | 15 | 20 | M30×2 | 16 | 90 | 48 | 38 | 61 | 19 | 45 | 11 | 09 | 32 |

| KHB-25SR | 315 | 20 | 20 | 25 | M36×2 | 18 | 109 | 60 | 48 | 70 | 25 | 55 | 11 | 12 | 41 |

| KHB-30SR | 315 | 25 | 25 | 30 | M42×2 | 20 | 120 | 65 | 57 | 79 | 28.5 | 64 | 11 | 12 | 50 |

| KHB-38SR | 315 | 32 | 30 | 38 | M52×2 | 22 | 153 | 84 | 75 | 101 | 37.5 | 84 | 12 | 14 | 60 |

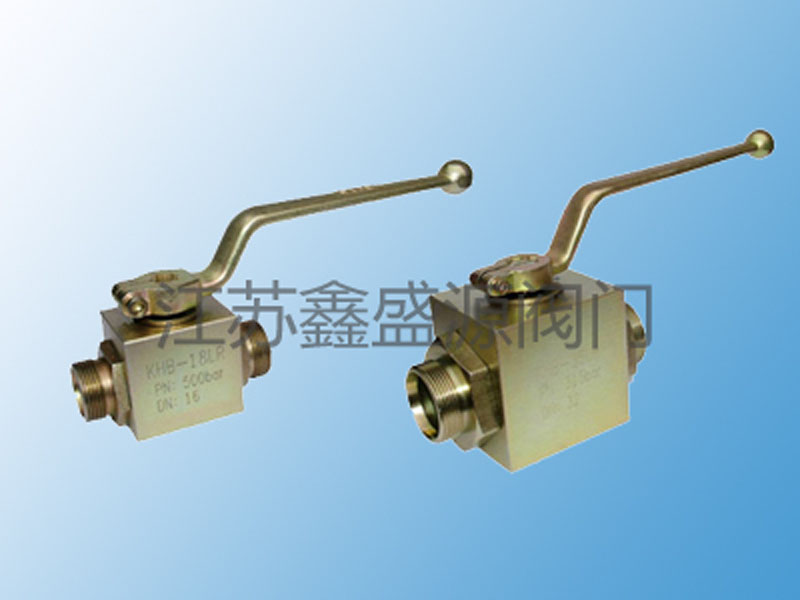

KHB系列高压球阀

KHB系列高压球阀是专为高压流体控制系统设计的核心阀门,广泛应用于石油、化工、矿山、工程机械等领域,核心功能是实现对液压油、水-乙二醇、压缩空气等介质的快速切断、流通控制与方向切换。

该系列阀门公称压力覆盖25MPa-63MPa,工作温度范围为-20℃-180℃(部分耐低温型号可达-40℃),适配多种严苛工况。阀体多采用锻钢、不锈钢材质,抗高压冲击与腐蚀能力强;球体经精密加工与硬化处理,配合丁晴橡胶、氟橡胶等密封件,实现高压下零泄漏密封。连接方式以螺纹连接(如G、NPT、PT螺纹)为主,部分型号支持板式连接,安装便捷且适配不同管路系统。操作方式涵盖手动(铝质/钢质手柄)、气动或电动执行器,可满足手动控制与自动化系统需求,部分衍生型号(如三通型KHB3K)还具备介质分流、合流功能,适配多通路控制场景。

KHB Series High-Pressure Ball Valve - Product Overview

The KHB Series High-Pressure Ball Valve is a core valve designed for high-pressure fluid control systems, widely used in petroleum, chemical, mining, construction machinery other fields. Its core function is to realize rapid cut-off, flow control direction switching of media such as hydraulic oil, water-glycol, compressed air.

This series of valves has a nominal pressure range of 25MPa-63MPa an operating temperature range of -20℃-180℃ (some low-temperature resistant models can reach -40℃), adapting to various harsh working conditions. The valve body is mostly made of forged steel stainless steel, with strong resistance to high-pressure impact corrosion; the ball is precision-machined hardened, matched with seals such as nitrile rubber fluororubber to achieve zero-leakage sealing under high pressure. The connection method is mainly thread connection (such as G, NPT, PT threads), some models support flanged connection, which is easy to install adapts to different pipeline systems. The operation methods include manual (aluminum/steel handle), pneumatic electric actuators, which can meet the needs of manual control automatic systems. Some derivative models (such as the three-way KHB3K) also have the functions of medium diversion confluence, adapting to multi-channel control scenarios.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!