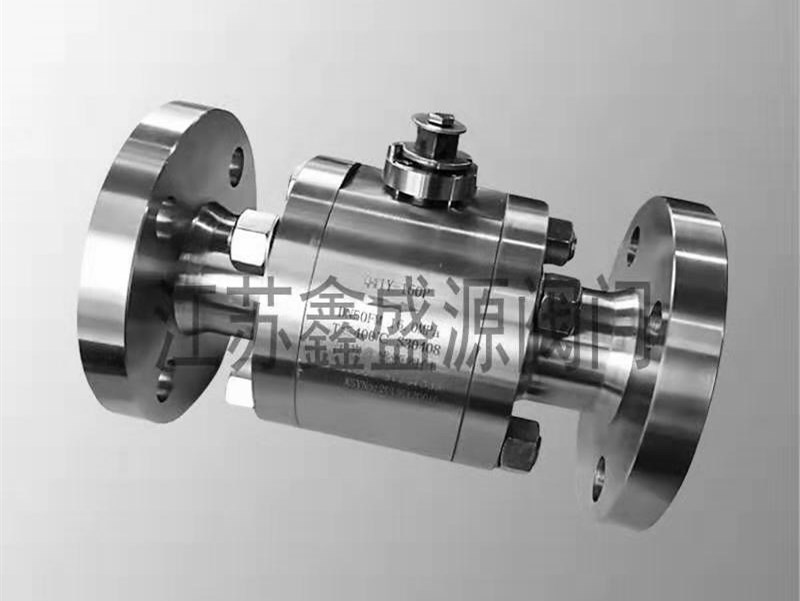

Q41N三段式法兰高压球阀适用范围用于石油、化工、冶金,电力、医药、造纸、制糖、航空、食品、机械等工业自控管路系统中。产品别名:高压法兰球阀。连接形式:法兰。主体材料:奥氏体不锈钢或碳钢。公称通径:DN50。适用介质油﹑水﹑气等多种非腐蚀性或腐蚀性介质。压力范围:1.6~42(Mpa)。适用温度:-20℃~ 1200℃(℃)。材质:不锈钢。压力环境:常压,(高压)可订货。工作温度:高温,(低温)可定货。标准:国标(美标)(非标)。类型:直通式。外形:中型。流动方向:直通。驱动方式:手动。

适用介质:油﹑水﹑气等多种非腐蚀性或腐蚀性介质(强腐蚀性介质)

适用温度:-20℃~440℃ -70℃~-240℃

制造材料:20#﹑1Cr18Ni9Ti﹑304﹑316﹑316L

定做压力:0—100MPa

Q41N三段式法兰高压球阀特点:

1、本产品所有部件均为锻件。

2、采用下装式阀杆,设置倒密封结构,确保填料处密封及防止阀杆脱出。

3、采用镶嵌式阀座。阀座背后设置O型圈,确保介质不外漏。

Q41N三段式法兰高压球阀主要零件材料:

| 零件名称 | 材质 | |

| GB | ASTM | |

| 阀体、阀盖 | WCB | A216-WCB |

| 密封圈 | 尼龙 | 尼龙 |

| 球体 | 1Cr18Ni9Ti | SS 304 |

| 阀座、阀杆 | 2Cr13 | A246-416 |

| O形圈 | 橡胶 | 橡胶 |

| 双头螺栓 | 35CrMoA | A193-B7 |

Q41N三段式法兰高压球阀主要性能规范:

| 公称压力PN | 16 | 32 | MPa |

| 强度试验压力PT | 24 | 48 | MPa |

| 低压密封试验力 | 0.6 | MPa | |

| 高压密封试验力 | 17.6 | 35.2 | MPa |

| 适用介质 | 水、油品、蒸汽 | ||

| 适用温度 | -40~80℃ | ||

Q41N三段式法兰高压球阀主要连接尺寸:

| 公称 压力 | 公称 通径 | 主要尺寸 | ||||||||||||||

| L | L1 | D | D1 | H | W | M | D2 | b | Z-Φd | |||||||

| 法兰 | 对焊 | 法兰 | 对焊 | 法兰 | 对焊 | 法兰 | 对焊 | 法兰 | 对焊 | 法兰 | ||||||

| 16.0 | 10 | 210 | 150 | 52 | 60 | 95 | 90 | 60 | 18 | 77 | 58 | 220 | M24×2 | 18 | 20 | 3-18 |

| 15 | 230 | 170 | 62 | 70 | 95 | 100 | 60 | 23 | 85 | 62 | 220 | M24×2 | 20 | 20 | 3-18 | |

| 20 | 240 | 190 | 73 | 80 | 105 | 110 | 68 | 29 | 94 | 75 | 250 | M33×2 | 28 | 20 | 3-18 | |

| 25 | 260 | 205 | 77 | 95 | 105 | 115 | 68 | 36 | 100 | 80 | 250 | M33×2 | 28 | 22 | 3-18 | |

| 32 | 300 | 230 | 100 | 110 | 115 | 150 | 80 | 43 | 120 | 96 | 300 | M42×2 | 38 | 24 | 4-18 | |

| 40 | 260 | 110 | 120 | 165 | 170 | 115 | 49 | 150 | 111 | 400 | M52×2 | 48 | 30 | 6-26 | ||

| 50 | 400 | 330 | 130 | 140 | 165 | 200 | 115 | 61 | 165 | 128 | 450 | M64×3 | 58 | 32 | 6-26 | |

| 65 | 490 | 360 | 140 | 150 | 200 | 225 | 145 | 80 | 180 | 180 | 500 | M80×3 | 74 | 40 | 6-29 | |

| 80 | 580 | 380 | 150 | 160 | 225 | 270 | 170 | 105 | 200 | 200 | 600 | M100×3 | 94 | 50 | 6-33 | |

| 100 | 620 | 430 | 178 | 188 | 260 | 320 | 195 | 118 | 245 | 245 | 800 | M125×4 | 115 | 60 | 6-36 | |

| 32.0 | 10 | 210 | 150 | 52 | 60 | 95 | 90 | 60 | 18 | 77 | 58 | 220 | M24×2 | 18 | 20 | 3-18 |

| 15 | 230 | 170 | 62 | 70 | 105 | 100 | 68 | 23 | 85 | 62 | 220 | M33×2 | 28 | 20 | 3-18 | |

| 20 | 240 | 190 | 73 | 80 | 105 | 110 | 68 | 29 | 94 | 75 | 250 | M33×2 | 28 | 20 | 3-18 | |

| 25 | 260 | 205 | 77 | 95 | 115 | 115 | 80 | 36 | 100 | 80 | 250 | M42×2 | 35 | 25 | 4-18 | |

| 32 | 300 | 230 | 100 | 110 | 165 | 150 | 115 | 43 | 120 | 96 | 300 | M52×2 | 41 | 30 | 4-22 | |

| 40 | 350 | 260 | 110 | 120 | 165 | 170 | 115 | 49 | 150 | 111 | 400 | M64×3 | 47 | 35 | 6-26 | |

| 50 | 400 | 330 | 130 | 140 | 200 | 200 | 145 | 61 | 165 | 128 | 450 | M80×3 | 70 | 40 | 6-29 | |

| 65 | 490 | 360 | 140 | 150 | 225 | 225 | 170 | 80 | 180 | 180 | 500 | M100×3 | 90 | 50 | 6-33 | |

| 80 | 580 | 380 | 150 | 160 | 260 | 270 | 195 | 105 | 200 | 200 | 600 | M125×4 | 112 | 55 | 6-36 | |

| 100 | 620 | 430 | 178 | 188 | 300 | 320 | 235 | 118 | 245 | 245 | 800 | M155×4 | 135 | 65 | 8-36 | |

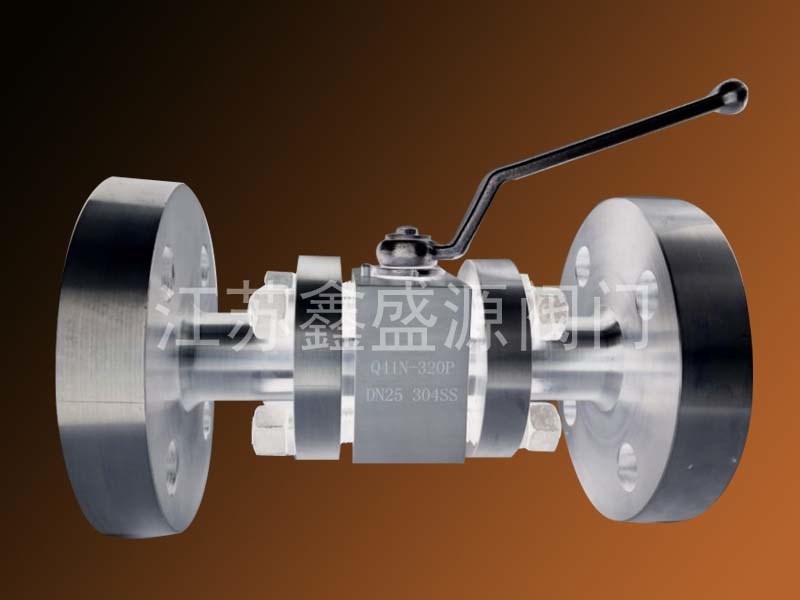

三段式法兰高压球阀

三段式法兰高压球阀是一种采用三段式阀体结构、通过法兰连接的高压流体控制阀门,兼具结构灵活性与高压耐受能力,广泛应用于石油、化工、天然气、电力等行业的高压管道系统。

三段式法兰高压球阀- 结构特点:阀体由左阀体、中阀体、右阀体三部分组成,通过螺栓连接为整体,便于拆卸和内部部件的维修更换;核心部件(如球体、阀座)多采用锻造合金钢材或不锈钢,经精密加工确保强度和密封性,能承受高压冲击;法兰接口符合行业标准(如ANSI、GB、DIN),可与对应规格的管道法兰紧密对接,安装稳固;阀座采用金属密封或高性能复合密封材料,适应高压工况下的密封需求,防止介质泄漏。

三段式法兰高压球阀- 工作原理:通过旋转阀杆带动球体旋转90°实现启闭。当球体通孔与管道通道中心线重合时,阀门全开,介质畅通无阻;当球体旋转至通孔与通道完全错开时,阀门关闭,截断介质流动。操作轻便,可配合手动、气动或电动执行器,满足不同场景的控制需求,尤其适合需要快速启闭的高压系统。

三段式法兰高压球阀- 性能优势:三段式结构设计使维修便捷,无需拆卸整个阀门即可更换密封件或球体,降低维护成本;高压耐受能力强,公称压力通常可达16MPa至100MPa,适用于严苛的高压工况;流体阻力小,全通径设计减少介质输送过程中的压力损失;密封性能好,在高压差下仍能保持良好的密封性,且具备抗冲刷、耐磨损特性,延长使用寿命;部分型号配备防静电、耐火结构,提升系统安全性。

三段式法兰高压球阀- 适用范围:适用于水、油、天然气、蒸汽、腐蚀性介质等多种高压流体,工作温度范围通常为-29℃至350℃(随材质变化),公称通径一般为DN15至DN300。广泛应用于高压管道的截断、接通或流向控制,是高压工业系统中的关键控制元件。

The three-piece flanged high-pressure ball valve is a high-pressure fluid control valve with a three-piece valve body structure flange connection. It combines structural flexibility high-pressure resistance, is widely used in high-pressure pipeline systems in petroleum, chemical, natural gas, electric power other industries.

The three-piece flanged high-pressure ball valve- Structural features: The valve body consists of three parts: left valve body, middle valve body right valve body, which are connected as a whole by bolts, facilitating disassembly maintenance of internal components. Core components (such as balls valve seats) are mostly made of forged alloy steel stainless steel, which are precision machined to ensure strength sealing performance, can withstand high-pressure impact. The flange interface complies with international industry standards (such as ANSI, GB, DIN), can be tightly connected with the pipeline flange of corresponding specifications, ensuring stable installation. The valve seat adopts metal sealing high-performance composite sealing materials to meet the sealing requirements under high-pressure working conditions prevent medium leakage.

The three-piece flanged high-pressure ball valve- Working principle: The valve is opened closed by rotating the valve stem to drive the ball to rotate 90°. When the through-hole of the ball coincides with the center line of the pipeline channel, the valve is fully open, allowing the medium to flow unimpeded; when the ball rotates until the through-hole is completely staggered the channel, the valve closes to cut off the medium flow. It is easy to operate can be equipped with manual, pneumatic electric actuators to meet the control needs of different scenarios, especially suitable for high-pressure systems requiring quick opening closing.

The three-piece flanged high-pressure ball valve- Performance advantages: The three-piece structure design makes maintenance convenient. Seals balls can be replaced without disassembling the entire valve, reducing maintenance costs. It has strong high-pressure resistance, with a nominal pressure usually ranging 16MPa to 100MPa, suitable for harsh high-pressure working conditions. It has low fluid resistance, the full-bore design reduces pressure loss during medium transportation. It has reliable sealing performance, which can maintain good sealing under high pressure difference, has anti-scouring wear-resistant characteristics, prolonging service life. Some models are equipped with anti-static fire-resistant structures to improve system safety.

The three-piece flanged high-pressure ball valve- Scope of application: It is suitable for various high-pressure fluids such as water, oil, natural gas, steam corrosive media. The working temperature range is usually -29℃ to 350℃ (varying with materials), the nominal diameter is generally DN15 to DN300. It is widely used for cutting off, connecting controlling the flow direction of high-pressure pipelines, is a key control component in high-pressure industrial systems.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!