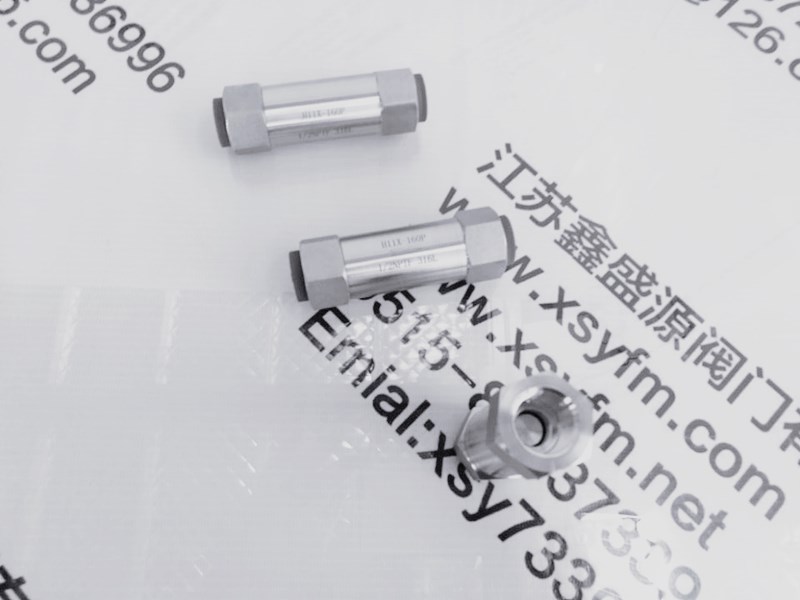

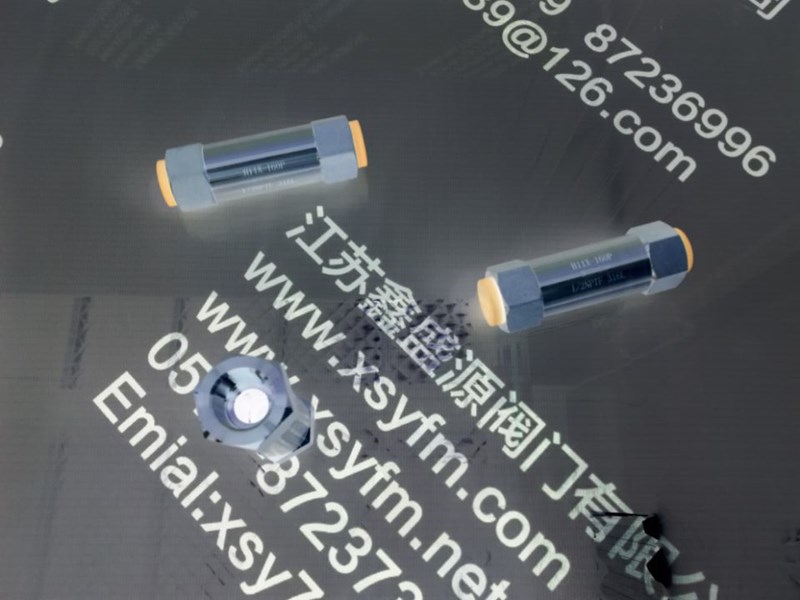

内螺纹高压止回阀的工作原理是在一个方向流动的流体压力作用下,阀瓣打开;流体反方向流动时,由流体压力和阀瓣的自重合阀瓣作用于阀座,从而切断流动。H11Y内螺纹高压止回阀又称为逆流阀、逆止阀、背压阀、单向阀。这类阀门是靠管路中介质本身的流动产生的力而自动开启和关闭的,属于一种自动阀门。止回阀用于管路系统,其主要作用是防止介质倒流、防止泵及其驱动电机机反转,以及容器内介质的泄放。H11Y内螺纹高压止回阀是通过螺纹连接管道,金属硬密封形式,可以达到零泄漏等级,具有安装方便 连接牢固 方便更换等优点。内螺纹形式有M G ZG NPT等。用户可根据各自情况选购。

内螺纹高压止回阀

内螺纹高压止回阀是一种阀体端部加工有内螺纹(Female Thread),并设计用于高压工况的止回阀。其核心功能是强制流体单向流动,并自动、稳定地阻止任何形式的介质反向倒流,是石油、化工、电力等行业高压系统中确保安全的关键部件。

内螺纹高压止回阀通过其内螺纹接口直接与带有外螺纹的管道或设备接口旋合连接。为承受高压,其阀体通常采用高强度合金钢或不锈钢锻件制造,内部密封副(如阀瓣与阀座)经过特殊硬化处理(如堆焊司太立合金),并配备重型弹簧,以确保在高压、高压差及流体脉动工况下能够迅速、严密地关闭。螺纹类型通常为美标NPT螺纹或公制细牙螺纹,以确保连接的强度和密封性。

内螺纹高压止回阀主要特点:

高压力等级: 设计承压能力高,通常用于Class 800、Class 1500、Class 2500及以上压力级别的管路系统。

结构紧凑: 相较于同压力等级的法兰阀门,螺纹连接结构更为紧凑,重量更轻,节省安装空间。

内螺纹高压止回阀高压密封性: 金属-to-金属硬密封或配合密封剂,确保在高压下仍具有密封性能,实现零泄漏。

耐冲刷与耐腐蚀: 内部元件常进行表面硬化处理,以耐受高压流体的冲刷和腐蚀。

内螺纹高压止回阀高强度结构: 锻件阀体能承受极高的管道应力及压力冲击。

内螺纹高压止回阀安装便捷: 螺纹连接方式简单,但需确保足够的拧紧力矩以达到密封要求。

内螺纹高压止回阀典型应用:

内螺纹高压止回阀石油与天然气行业:高压井口装置、节流管汇、压裂设备。

内螺纹高压止回阀高压注水系统:油田注水泵出口。

内螺纹高压止回阀化工与石化过程:高压反应器进出口、物料输送管线。

内螺纹高压止回阀能源电力:高压锅炉给水系统、蒸汽管道。

内螺纹高压止回阀高压测试设备、液压动力系统。

Product Overview of High-Pressure Female Threaded Check Valves

Product Overview:

A High-Pressure Female Threaded Check Valve is a type of check valve with internal female threads on its body ends, designed for high-pressure services. Its core function is to enforce unidirectional fluid flow automatically reliably prevent any form of media backflow. It is a critical safety component in high-pressure systems in industries such as oil, chemical, power.

The valve connects by screwing its female threaded port directly onto a male-threaded pipe equipment interface. To withstand high pressure, the valve body is typically manufactured high-strength alloy steel stainless steel forgings. The internal sealing pair (e.g., disc seat) is specially hardened (e.g., with Stellite overlay) paired with a heavy-duty spring to ensure rapid tight closing under high pressure, high pressure differential, fluid pulsation conditions. The thread type is usually NPT (National Pipe Taper) thread metric fine pitch thread to ensure connection strength sealing.

Key Features:

High Pressure Rating: Designed for high pressure containment, commonly used in Class 800, Class 1500, Class 2500, higher piping systems.

Compact Structure: Compared to flanged valves of the same pressure class, the threaded connection structure is more compact, lighter, saves installation space.

High-Pressure Sealing: Metal-to-metal hard sealing used with high-quality sealant ensures excellent sealing performance under high pressure, achieving zero leakage.

Erosion & Corrosion Resistance: Internal components are often surface-hardened to withstand erosion corrosion high-pressure fluids.

High-Strength Construction: The forged body can withstand extreme pipe stress pressure shocks.

Convenient Installation: The threaded connection is simple, but sufficient tightening torque must be ensured to meet sealing requirements.

Typical Applications:

Oil & Gas Industry: High-pressure wellhead equipment, choke kill manifolds, fracturing equipment.

High-Pressure Water Injection Systems: Outlet of oilfield water injection pumps.

Chemical & Petrochemical Processes: Inlet/outlet of high-pressure reactors, process transfer lines.

Power Industry: High-pressure boiler feedwater systems, steam lines.

High-pressure test equipment, hydraulic power systems.

关键术语翻译 (Key Terminology Translation):

内螺纹高压止回阀: High-Pressure Female Threaded Check Valve

内螺纹: Female Thread / Internal Thread

高压工况: High-Pressure Service

锻件: Forging / Forged Body

硬化处理: Hardening / Hard-Facing

司太立合金: Stellite

NPT螺纹: NPT Thread (National Pipe Taper Thread)

零泄漏: Zero Leakage

压力等级: Pressure Class (e.g., ASME Class 2500)

耐冲刷: Erosion Resistance

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!