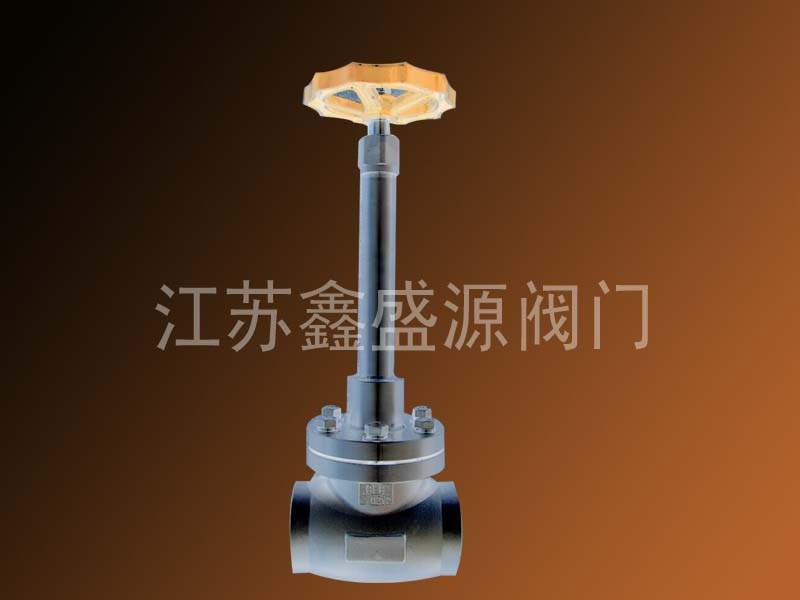

DJ61F美标低温焊接截止阀此类型低温截止阀主要用于低温液体贮运设备、液化天然气LNG的加气、转运系统,具有开关灵活、密封稳定的特点,也可用于其他低温和深冷介质的管理系统。

适用温度:-196℃~+200℃

阀体:不锈钢

阀盖:不锈钢

阀杆:不锈钢

密封圈:聚四氟乙烯

适用介质:氧气、氮气、氩气、二氧化碳、惰性气体等.

美标低温焊接截止阀主要外形及连接尺寸:

| 产品代号 | H(开) | H(关) | A | L | D | D1 | D2 |

| 10 DJ61F-40P | 253 | 248 | 65 | 8 | Ф60 | Ф10 | Ф14.5 |

| 15 DJ61F-40P | 253 | 248 | 65 | 8 | Ф60 | Ф15 | Ф18.5 |

| 20 DJ61F-40P | 308 | 300 | 80 | 10 | Ф90 | Ф20 | Ф25.5 |

| 25 DJ61F-40P | 308 | 300 | 80 | 10 | Ф90 | Ф25 | Ф28.5 |

| 32 DJ61F-40P | 352 | 340 | 100 | 10 | Ф110 | Ф32 | Ф38.5 |

| 40 DJ61F-40P | 352 | 340 | 100 | 12 | Ф110 | Ф40 | Ф45.5 |

| 50 DJ61F-40P | 430 | 413 | 160 | 15 | Ф160 | Ф50 | Ф57.5 |

| 65 DJ61F-40P | 435 | 418 | 180 | 20 | Ф160 | Ф65 | Ф70.5 |

| 80 DJ61F-40P | 480 | 460 | 200 | 30 | Ф240 | Ф80 | Ф89.5 |

| 100 DJ61F-40P | 480 | 460 | 220 | 30 | Ф240 | Ф100 | Ф108.5 |

美标低温焊接截止阀

美标低温焊接截止阀是按照美国标准设计和制造的专用阀门,采用焊接端连接方式,适用于-46℃至-196℃的低温工况。该阀门通过焊接方式与管道系统形成长久性连接,确保在低温高压环境下实现零泄漏密封,广泛应用于LNG、液氮、液氧等低温介质的输送系统。

美标低温焊接截止阀核心特点:

美标低温焊接截止阀美标规范设计

符合ASME B16.34压力温度等级

材料认证符合ASTM标准

焊接端符合ASME B16.25坡口标准

焊接连接优势

消除法兰泄漏点

提高系统密封稳定性

减少维护需求

低温性能稳定

美标低温焊接截止阀主体材料经深冷处理

加长阀盖设计(小150mm)

低温专用填料系统

高压密封性能

压力等级Class 800-1500

波纹管密封+石墨填料双重保障

通过API 598密封试验

美标低温焊接截止阀典型应用:

LNG液化工厂工艺管道

空分装置低温液体管道

低温储罐进出口管道

航天燃料输送系统

低温试验装置

Product Overview of American Standard Cryogenic Welded Globe Valves

American Standard Cryogenic Welded Globe Valves are specialized valves designed manufactured according to US standards, featuring welded end connections for applications in cryogenic service -46℃ to -196℃. These valves form permanent connections with piping systems through welding, ensuring zero-leakage sealing under cryogenic high-pressure conditions, widely used in transmission systems for LNG, liquid nitrogen, liquid oxygen other cryogenic media.

Key Features:

US Standard Design

Complies with ASME B16.34 pressure-temperature ratings

Material certifications per ASTM standards

Welding ends per ASME B16.25 bevel standards

Welded Connection Advantages

Eliminates flange leakage points

Enhances system sealing reliability

Reduces maintenance requirements

Cryogenic Performance Assurance

Deep-cryo treated body materials

Extended bonnet design (min. 150mm)

Cryogenic-specific packing system

High-Pressure Sealing Performance

Pressure Class 800-1500

Bellows seal + graphite packing double protection

API 598 seal test certified

Typical Applications:

LNG liquefaction plant process piping

Cryogenic liquid pipelines in air separation units

Storage tank inlet/outlet pipelines

Aerospace fuel delivery systems

Cryogenic test facilities

Technical Specifications:

Size Range: 1/2" to 8"

Pressure Class: Class 800-1500

Temperature Range: -196℃ to +80℃

End Connections: BW (Butt Weld), SW (Socket Weld)

Body Materials: LF2, A352 LCB, A351 CF8/CF8M

Standards Compliance:

Design: ASME B16.34

Testing: API 598, MSS SP-117

Fire Safe: API 607

Materials: ASTM A352, A351, A182

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!