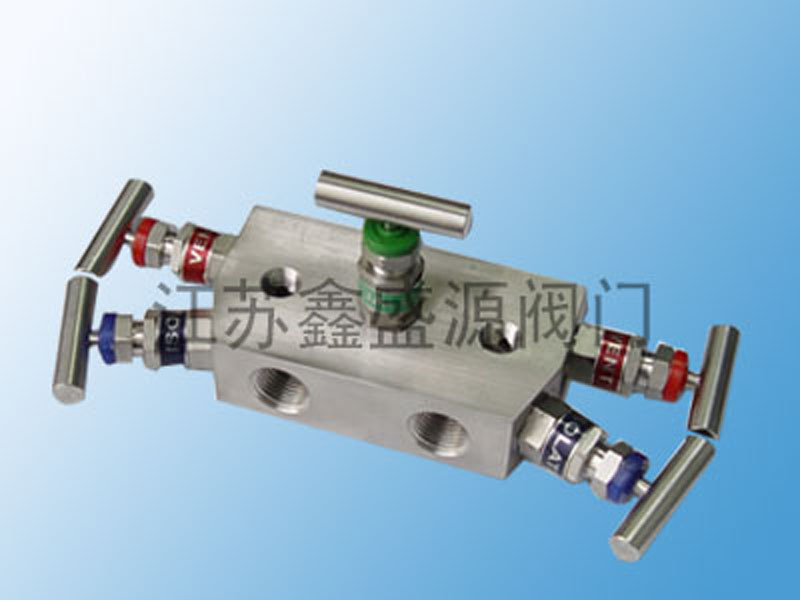

产品名称:分体安装五阀组

产品型号:RCCT5

所属类别:仪表阀组 >> 五阀组

所属系列:RC

| 订货信息 | ||||

| 代码 | 结构件材料 | |||

| 阀体 | 阀帽 | 阀杆 | 泄放/排污堵头 | |

| 1 | 304SST | 304SST | 304SST | 304SST |

| 2 | 316SST | 316SST | 316SST | 316SST |

| 代码 | 填料 | |||

| 1 | 四氟乙烯 | |||

| 2 | 石墨 | |||

| 代码 | DR阀组选项 | |||

| 共面型阀组支架 | ||||

| B4 | 用于2-in.管安装的不锈钢支架 300 不锈钢螺栓 | |||

| 清洗 | ||||

| P2 | 特殊清洗(禁油),仅适用填料为四氟乙烯的场合 | |||

| 接头(用于阀组类型代码C) | ||||

| CA | 1/2-14NPTM-Ф14×2对焊接头 | |||

| CB | 1/2-14NPTM-Ф1/2-in卡套接头 | |||

| CC | 1/2-14NPTM-Ф12卡套接头 | |||

| CD | 1/2-14NPTM-Ф6卡套接头 | |||

| CS | 定制接头 | |||

| 接头(用于阀组类型代码T) | ||||

| TA | 1/4-18NPTM-Ф14×2 对焊接头 | |||

| TB | 1/4-18NPTM-Ф1/2-in 卡套接头 | |||

| TC | 1/4-18NPTM-Ф12 卡套接头 | |||

| TD | 1/4-18NPTM-Ф6 卡套接头 | |||

| TS | 定制接头 | |||

| 转换法兰(用于阀组类型代码T) | ||||

| DF | 1/2-14 NPTF 转换法兰 | |||

| DS | 定制法兰 | |||

| 过程法兰连接孔规格(用于阀组类型代码T) | ||||

| HK | M10×1.5 内螺纹 | |||

| 组装 | ||||

| IA | 与仪表一体化组装并打压测试 | |||

分体安装五阀组

分体安装五阀组是一种专为差压变送器设计的高集成度、模块化的仪表阀门组件。其核心功能是为差压测量系统提供压力引导、过程隔离、在线校验和零点迁移。

分体安装五阀组“分体安装”是指该阀组的两个压力容室(高压侧和低压侧)是分离的,通过外部引压管线分别连接到过程管道的两个取压点。这种设计使其能够灵活地适应不同间距的取压口安装需求,尤其适用于大管径或取压点距离较远的差压测量场合(如大口径流量测量)。

分体安装五阀组标准的五阀功能包括:

两个高压/低压隔离阀:分别切断正负压侧与过程的连接。

一个平衡阀:连通正负压容室,用于保护变送器膜盒免受单侧过压冲击,并方便零点校验。

两个排污/泄放阀:分别用于正负压侧的引压管排污或气体介质泄放。

其核心优势在于集成化设计减少了安装接头和泄漏点,平衡阀有效保护了昂贵的变送器,并通过一体化结构实现了安全、便捷的在线操作和维护。

分体安装五阀组主要特点:

分体式结构: 高低压腔体分离,通过钢管或软管连接,安装布局灵活。

功能集成: 将五个阀的功能集于一体,结构紧凑,减少泄漏点。

安全维护: 可在不停车的情况下,对变送器进行隔离、校验、排污和零点调整。

分体安装五阀组保护变送器: 平衡阀能有效防止变送器膜盒因差压过载而损坏。

分体安装五阀组多种连接: 提供法兰、螺纹等多种过程接口和变送器接口选项。

分体安装五阀组典型应用:

主要用于石油、化工、电力、冶金等行业中,与差压变送器配套使用,进行流量、液位、密度的测量,特别适用于蒸汽、气体、高压及危险介质的大型管道流量测量系统。

Separately Mounted 5-Valve Manifold Product Overview

A Separately Mounted 5-Valve Manifold is a highly integrated modular instrumentation valve package specifically designed for differential pressure (DP) transmitters. Its core functions are to provide pressure guidance, process isolation, in-line calibration, zero migration for differential pressure measurement systems.

"Separately Mounted" means that the two pressure chambers (high-pressure low-pressure sides) of the manifold are physically separated. They are connected to the two process pressure taps via external impulse lines. This design offers flexibility to adapt to various distances between pressure taps, making it particularly suitable for differential pressure applications with large pipe diameters widely spaced tap locations (e.g., large diameter flow measurement).

The standard five-valve functionality includes:

Two Block Valves (HP/LP): Isolate the positive negative pressure sides the process.

One Equalizing Valve: Connects the HP LP chambers to protect the transmitter diaphragm overrange pressure facilitate zero checking.

Two Vent/Drain Valves: Used for venting (gas services) draining (liquid services) on the HP LP impulse lines.

Its core advantages are that the integrated design reduces installation fittings potential leak points, the equalizing valve effectively protects the expensive transmitter, the unified structure enables safe convenient online operation maintenance.

Key Features:

Split Body Design: Separate HP LP chambers connected by tubing hoses, allowing for flexible installation layout.

Integrated Functionality: Combines the functions of five valves into one compact unit, minimizing leak points.

Safe Maintenance: Allows for transmitter isolation, calibration, venting/draining, zero adjustment without process shutdown.

Transmitter Protection: The equalizing valve prevents damage to the transmitter's diaphragm differential pressure overrange.

Multiple Connections: Offers various process connections (flanged, threaded) transmitter interface options.

典型应用 (Typical Applications):

Primarily used in industries such as oil & gas, chemical, power generation, metallurgy. It is paired with DP transmitters for measuring flow, level, density, especially in large pipeline flow measurement systems for steam, gas, high-pressure, hazardous media.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!