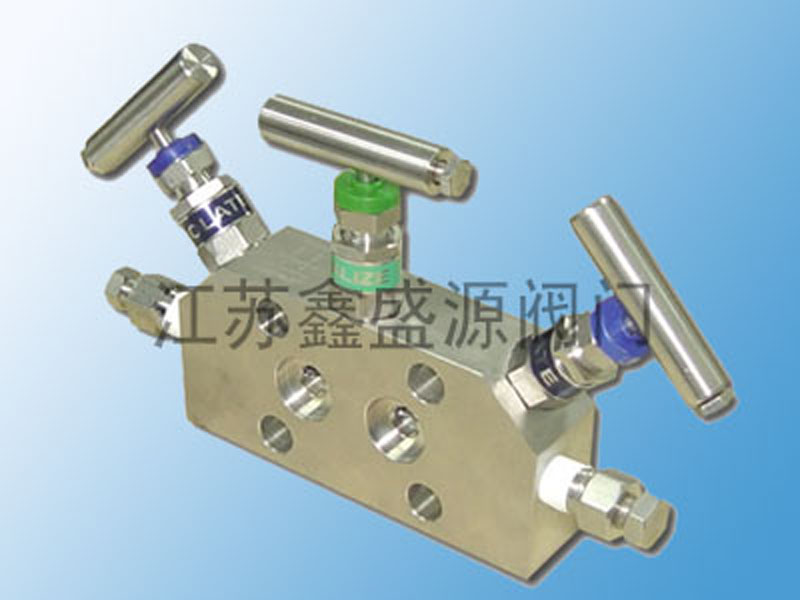

产品名称:共面型三阀组

产品型号:DRCC3

所属类别:仪表阀组 >> 三阀组

所属系列:DR

共面型三阀组安装尺寸图

| 订货信息 | ||||

| 代码 | 结构件材料 | |||

| 阀体 | 阀帽 | 阀杆 | 泄放/排污堵头 | |

| 1 | 304SST | 304SST | 304SST | 304SST |

| 2 | 316SST | 316SST | 316SST | 316SST |

| 代码 | 填料 | |||

| 1 | 四氟乙烯 | |||

| 2 | 石墨 | |||

| 代码 | DR阀组选项 | |||

| 共面型阀组支架 | ||||

| B4 | 用于2-in.管安装的不锈钢支架 300 不锈钢螺栓 | |||

| 清洗 | ||||

| P2 | 特殊清洗(禁油),仅适用填料为四氟乙烯的场合 | |||

| 接头(用于阀组类型代码C) | ||||

| CA | 1/2-14NPTM-Ф14×2对焊接头 | |||

| CB | 1/2-14NPTM-Ф1/2-in卡套接头 | |||

| CC | 1/2-14NPTM-Ф12卡套接头 | |||

| CD | 1/2-14NPTM-Ф6卡套接头 | |||

| CS | 定制接头 | |||

| 接头(用于阀组类型代码T) | ||||

| TA | 1/4-18NPTM-Ф14×2 对焊接头 | |||

| TB | 1/4-18NPTM-Ф1/2-in 卡套接头 | |||

| TC | 1/4-18NPTM-Ф12 卡套接头 | |||

| TD | 1/4-18NPTM-Ф6 卡套接头 | |||

| TS | 定制接头 | |||

| 转换法兰(用于阀组类型代码T) | ||||

| DF | 1/2-14 NPTF 转换法兰 | |||

| DS | 定制法兰 | |||

| 过程法兰连接孔规格(用于阀组类型代码T) | ||||

| HK | M10×1.5 内螺纹 | |||

| 组装 | ||||

| IA | 与仪表一体化组装并打压测试 | |||

共面型三阀组

共面型三阀组是一种与差压变送器配套使用的高集成度阀门组件,其核心特征是三个阀门(两个隔离阀和一个平衡阀)的操作端口(阀杆或手轮)位于同一平面。这种设计使其结构异常紧凑,操作空间集中,便于安装和维护。

共面型三阀组专为差压测量系统设计,主要功能包括过程隔离、零点校验/迁移和过压保护。其标准操作流程(先开平衡阀,再同开/关隔离阀,之后关平衡阀)能有效避免差压变送器的敏感膜盒在投运或停运时承受单向过压而损坏。

共面型三阀组“共面”设计是其区别于传统错位布置三阀组的主要特点。所有阀杆轴线平行且端部齐平,不仅节省了安装空间,尤其适用于空间受限的场合,也使操作更加方便顺手。

共面型三阀组主要特点:

共面设计: 所有阀杆/手轮位于同一平面,结构紧凑,操作空间集中。

集成化高: 三阀一体,减少了连接点和潜在的泄漏点。

保护变送器: 内置平衡阀是保护差压变送器膜盒的核心安全部件。

操作便捷: 优化的空间布局使操作更顺手,标准流程确保安全。

安装方便: 通常直接安装在变送器本体上,节省管路和空间。

共面型三阀组典型应用:

广泛应用于石油、化工、电力、冶金等行业的流程中,与差压变送器配套,用于测量管道或容器内流体的流量、液位和密度。

Coplanar 3-Valve Manifold Product Overview

The Coplanar 3-Valve Manifold is a highly integrated valve package used with differential pressure (DP) transmitters. Its defining feature is that the operating ports (stems handwheels) of all three valves (two block valves one equalizing valve) are located on the same plane. This design results in an exceptionally compact structure with centralized operation space, facilitating easy installation maintenance.

Designed specifically for differential pressure measurement systems, its primary functions include process isolation, zero checking/migration, overpressure protection. The standard operating procedure (open equalizing valve first, then open/close both block valves simultaneously, finally close equalizing valve) effectively prevents the sensitive diaphragm of the DP transmitter being damaged by unilateral overpressure during startup shutdown.

The "Coplanar" design is its main distinguishing feature compared to traditional manifolds with staggered valve arrangements. All valve stem axes are parallel their ends are flush, which only saves installation space (particularly valuable in confined areas) but also makes operation more convenient ergonomic.

Key Features:

Coplanar Design: All valve stems/handwheels are on the same plane, offering a compact structure centralized operation space.

High Integration: Three valves in one body, reducing connection points potential leaks.

Transmitter Protection: The internal equalizing valve is the core safety component that protects the DP transmitter's diaphragm.

Operational Convenience: The optimized spatial layout allows for ergonomic operation, the standard procedure ensures safety.

Easy Installation: Typically mounted directly onto the transmitter body, saving piping space.

Typical Applications:

Widely used in process industries such as oil & gas, chemical, power generation, metallurgy. It is paired with DP transmitters for measuring flow, level, density of fluids in pipelines vessels.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!