Q11N内螺纹锻钢球阀应用规范:

公称压力:10-50MPa

适用温度范围:-20~550℃

适用介质:水、油、气及某些腐蚀性液体。

螺纹类型:G·NPT BSPT.BSP.DIN259/2999

Q11N内螺纹锻钢球阀主要零件材料:

| 零件名称 | 阀体 | 球体 | 阀杆 | 密封圈 |

| Q11N-100C Q11N-160C Q11N-320C | 35/45 | 1Cr18 | 1Cr18Ni9Ti | 尼龙 |

| Q11N-100P Q11N-160P Q11N-320P | 304/1Cr18Ni9Ti | 304/1Cr18Ni9Ti | ||

| Q11N-100R Q11N-160R Q11N-320R | 316/Cr18Ni12Mo2Ti | 316/1Cr18Ni9Ti | ||

Q11N内螺纹锻钢球阀美标主要尺寸:

| 口径 | d | L | L1 | H | W | D | L3 |

| 流量 | 总长 | 中段瓣总长 | 中心高度 | 手柄长度 | 半插口 | 有效长度 | |

| NPT3/8″ | 10 | 100 | 60 | 62 | 150 | 1780 | 10 |

| NPT1/2″ | 14 | 100 | 60 | 65 | 150 | 21.85 | 10 |

| NPT3/4″ | 19 | 140 | 80 | 74 | 180 | 27.30 | 13 |

| NPT1″ | 24 | 140 | 80 | 80 | 180 | 34.05 | 13 |

| NPT11/4″ | 31 | 160 | 90 | 95 | 255 | 42.80 | 13 |

| NPT11/2″ | 39 | 180 | 100 | 98 | 255 | 48.80 | 13 |

| NPT2″ | 48 | 200 | 110 | 108 | 255 | 61.35 | 16 |

| NPT21/2″ | 63 | - | - | - | - | 74.20 | 16 |

| NPT3″ | 78 | - | - | - | - | 90.15 | 16 |

| NPT4″ | 98 | - | - | - | - | 115.80 | 19 |

采用:ASME、B16.11-1991标准。

Q11N内螺纹锻钢球阀国标主要尺寸:

| 公称通径 DN(mm) | Q11N-100/160、Q11N-100/160P | Q11N-320、Q11N-320P | |||||||||

| 管螺纹 | 尺寸(mm) | 管螺纹 | 尺寸(mm) | ||||||||

| d | L | H | W | E | H | W | SW | L | |||

| 5 | 1/4 | 11 | 70 | 43 | 108 | 42.5 | - | - | - | - | 70 |

| 10 | 3/8 | 11 | 70 | 43 | 108 | 42.5 | - | - | - | - | - |

| 15 | 1/2 | 11 | 85 | 43 | 108 | 42.5 | 1/2 | 68 | 130 | 41 | 85 |

| 20 | 3/4 | 14 | 95 | 45.5 | 146 | 47.5 | 3/4 | 77 | 180 | 46 | 95 |

| 25 | 1 | 21 | 105 | 59.5 | 146 | 52.5 | 1 | 82 | 180 | 55 | 105 |

| 32 | 11/4 | 25 | 120 | 64.5 | 146 | 60 | 11/4 | 115 | 300 | 70 | 120 |

| 40 | 11/2 | 32 | 130 | 76 | 254 | 65 | 11/2 | 120 | 300 | 80 | 130 |

| 50 | 2 | 38 | 150 | 81 | 254 | 75 | 2 | 130 | 300 | 100 | 15 |

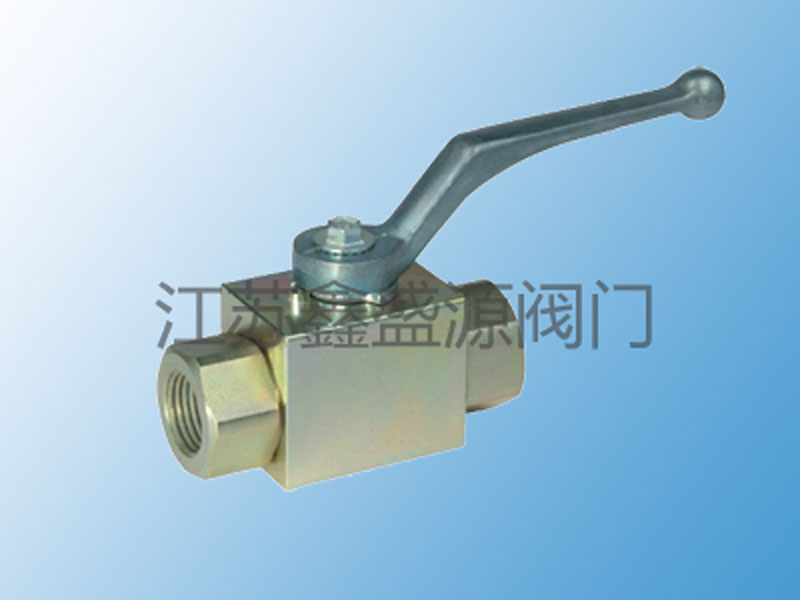

内螺纹锻钢球阀产品概述

内螺纹锻钢球阀是一种采用锻造工艺生产阀体(材质以钢材为主)、通过内螺纹连接的球阀,具有结构强度高、密封性好、耐高压的特点,主要用于工业管路系统中控制介质的通断,尤其适用于对阀门强度和连接性有较高要求的场景。

内螺纹锻钢球阀- 结构与材质:阀体采用整体锻造工艺,无铸造缺陷,材质多为碳钢、不锈钢或合金钢材(如A105、F304、F316等),机械强度高,抗冲击和耐高压性能好,能适应中高压工况(通常压力等级可达PN16~PN420或Class 150~Class 2500)。

内螺纹锻钢球阀- 连接方式:采用内螺纹连接(如NPT、BSPT等标准螺纹),可直接与外螺纹管道或设备对接,连接紧密,安装拆卸便捷,无需额外密封件,适合中小口径管道(一般DN15~DN50)。

内螺纹锻钢球阀- 密封性能:阀座采用耐温、耐腐材料(如增强聚四氟乙烯、金属密封件等),配合球体的高精度研磨,密封稳定,可实现低泄漏甚至零泄漏,满足高压下的密封要求。

内螺纹锻钢球阀- 操作与安全:多为手动操作,手柄旋转90°即可完成全开或全关,操作轻便;阀杆采用防吹出结构和填料密封设计,防止高压介质泄漏,提升操作安全性。

内螺纹锻钢球阀- 应用领域:广泛应用于石油化工、天然气、电力、冶金、液压系统等工业领域,尤其适用于高压、高温或有振动的管路系统,适配水、油、气体、腐蚀性介质等多种流体。

The internal thread forged steel ball valve is a type of ball valve with a valve body produced by forging process (mainly made of steel) connected via internal threads. It features high structural strength, good sealing performance, high-pressure resistance, mainly used to control the on-off of media in industrial pipeline systems, especially suitable for scenarios with high requirements for valve strength connection reliability.

The internal thread forged steel ball valve- Structure material: The valve body is manufactured by integral forging process without casting defects. The material is mostly high-quality carbon steel, stainless steel, alloy steel (such as A105, F304, F316, etc.), with high mechanical strength, excellent impact resistance high-pressure resistance, capable of adapting to medium high-pressure working conditions (usually with pressure ratings up to PN16~PN420 Class 150~Class 2500).

The internal thread forged steel ball valve- Connection method: Adopts internal thread connection (such as NPT, BSPT other standard threads), which can be directly connected to external thread pipelines equipment. The connection is tight, installation disassembly are convenient without additional seals, suitable for small medium-diameter pipelines (generally DN15~DN50).

The internal thread forged steel ball valve-Sealing performance: The valve seat is made of temperature-resistant corrosion-resistant materials (such as reinforced PSeE, metal seals, etc.). Combined with high-precision grinding of the ball, it provides reliable sealing, achieving low leakage even zero leakage, meeting the sealing requirements under high pressure.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!