KHP系列板式球阀图形符号:

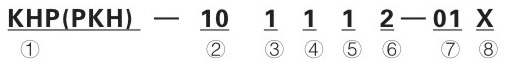

KHP系列板式球阀型号说明:

①系列代号:KHP(PKH)系列板式球阀

②公称通径:6、10、16、20、25、32、40、50mm

③阀体材料:1-钢

④球体材料:1-钢、2-黄铜

⑤工作温度:1、-25~+100℃ 2、-30~+170℃

⑥其他密封:2-丁腈橡胶、4-氟橡胶

⑦手柄形式:01-铝质直柄02-铝质曲柄03-铸锌直柄04-铸锌曲柄05-钢质直柄06-钢质曲柄09-不带手柄

⑧设计序号:由生产商定

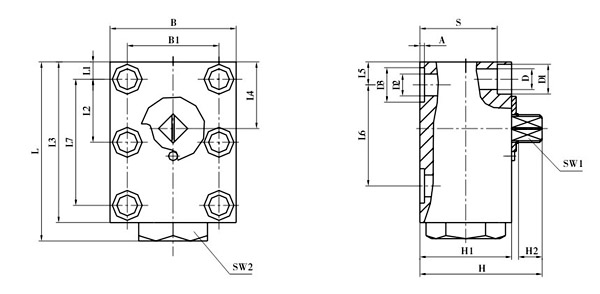

KHP系列板式球阀外形尺寸:

KHP系列板式球阀尺寸表:

| 简略型号 | DN | LW | L | L1 | L2 | L3 | L4 | L5 | L6 | L7 | B | B1 |

| KHP-06 | 06 | 06 | 64 | 8.5 | 17.5 | 59 | 25 | 8.5 | 35 | 35 | 40 | 27 |

| KHP-10 | 10 | 9.5 | 77 | 7.5 | 27.5 | 70 | 29 | 10 | 44 | 55 | 55 | 40 |

| KHP-16 | 16 | 16 | 110 | 8.5 | 41.5 | 100 | 43 | 17 | 58 | 83 | 60 | 45 |

| KHP-20 | 20 | 20 | 126 | 10 | 48.5 | 117 | 54 | 20 | 69 | 97 | 70 | 51 |

| KHP-25 | 25 | 23.5 | 145 | 10 | 57.5 | 135 | 64.5 | 24 | 81 | 115 | 80 | 60 |

| KHP-32 | 32 | 30 | 177 | 12 | 68 | 165 | 75.5 | 29 | 96 | 136 | 100 | 78 |

| KHP-40 | 40 | 38 | 200 | 30 | 56 | 185 | 80 | 30 | 112 | 112 | 130 | 95 |

| KHP-50 | 50 | 48 | 245 | 38 | 68 | 220 | 106 | 38 | 136 | 136 | 149 | 112 |

| 简略型号 | SW1 | SW2 | H | H1 | H2 | D | D1 | D2 | D3 | A | S | O 形圈 |

| KHP-06 | 09 | 22 | 37.5 | 30 | 7 | 6.6 | 11 | 6 | 11.7 | 1.6 | 23 | 8×2 |

| KHP-10 | 09 | 30 | 58 | 40 | 8.5 | 9 | 13 | 9.5 | 15 | 2 | 31 | 10×2.6 |

| KHP-16 | 09 | 41 | 72.5 | 52 | 11 | 9 | 13 | 16 | 25 | 2 | 43 | 20.29×2.62 |

| KHP-20 | 12 | 41 | 88.5 | 60 | 11 | 10.5 | 16.5 | 20 | 30 | 2.5 | 50 | 23.39×3.53 |

| KHP-25 | 12 | 46 | 97.5 | 65 | 11 | 10.5 | 17 | 23.5 | 35 | 2.5 | 55 | 28.17×3.53 |

| KHP-32 | 14 | 55 | 118.5 | 80 | 12 | 13 | 19 | 30 | 40 | 2.5 | 67 | 32.92×3.53 |

| KHP-40 | 14 | 65 | 118.5 | 93 | 12 | 17 | 25 | 38 | 48 | 3 | 77 | 42×3.5 |

| KHP-50 | 14 | / | 129 | 110 | 12 | 22 | 33 | 48 | 55.4 | 2.9 | 88.5 | 49×3.5 |

| 简略型号 | 内六角螺栓DIN912 | 扭距 Nm(摩擦系数μ=0.14时) |

| KHP-06 | M6-10.9 | 13 |

| KHP-10 | M8-10.9 | 30 |

| KHP-16 | M8-12.9 | 35 |

| KHP-20 | M8-12.9 | 60 |

| KHP-25 | M10-12.9 | 60 |

| KHP-32 | M12-12.9 | 110 |

| KHP-40 | M16-12.9 | 300 |

| KHP-50 | M20-12.9 | 600 |

KHP系列板式球阀

- KHP系列板式球阀基本信息[__LINK_ICON]:系列代号为KHP,公称通径为DN6-DN50,阀体材质有铸钢、不锈钢等,球体材料为钢或黄铜,制造标准包括国标GB、德国DIN、美国API等。

- KHP系列板式球阀性能特点[__LINK_ICON]:开关迅速、方便,流体阻力小,阀杆转动90°即可完成全开或全关动作。阀杆密封稳定,启闭时阀杆只作旋转运动,填料密封不易被破坏,且倒密封的密封力随介质压力增加而增大。

- KHP系列板式球阀技术参数:公称压力为25MPA-50MPA,工作温度为-20℃-170℃,密封材料有丁晴橡胶、氟橡胶等,手柄形式包括铝质直柄、铝质曲柄、铸锌直柄等多种类型,也可不带手柄。

- 应用领域:广泛应用于石油、化工、冶金、机械等行业,用于控制介质的流通和截止。

1. Product Overview

The KHP Series Flanged Ball Valve is a high-performance industrial valve designed for on-off throttling control of various fluid media. It features a flanged connection structure, which ensures reliable sealing easy installation in pipeline systems. With its compact design, excellent corrosion resistance, long service life, this series is widely used in petroleum, chemical, water treatment, power generation industries.

2. Core Features

- Robust Construction: Adopts high-quality metal materials (such as carbon steel, stainless steel) for valve body ball, ensuring resistance to high pressure, high temperature, mechanical wear.

- Superior Sealing Performance: Equipped with advanced sealing rings (PTFE, RPTFE, metal seals), achieving zero leakage even under harsh working conditions.

- Smooth Operation: The integrated valve stem ball design reduces friction, enabling light flexible operation, supports both manual automatic (electric/pneumatic) control modes.

- Wide Media Compatibility: Suitable for handling water, oil, gas, steam, corrosive chemical fluids, with customizable material options for specific media requirements.

3. Technical Specifications

- Model: KHP Series (e.g., KHP-16C, KHP-25P, etc., with suffixes indicating pressure rating material)

- Nominal Diameter (DN): Typically ranges DN15 to DN600 ( 1/2" to 24" in imperial units)

- Nominal Pressure (PN): PN10 to PN160 ( Class 150 to Class 900)

- Operating Temperature: -20℃ to 350℃ (varies by material seal type; low-temperature models can reach -196℃)

- Connection Standard: Complies with international standards such as GB/T, ANSI, DIN, JIS for flanged connections

- Control Mode: Manual (handwheel/lever), electric actuator, pneumatic actuator

- Valve Body Material: Carbon steel (WCB), stainless steel (304, 316, 316L), alloy steel, etc.

- Ball Material: Same as valve body hardened stainless steel (for wear resistance)

- Seal Material: PTFE (for general use), RPTFE (high temperature resistance), metal (for ultra-high temperature/pressure)

4. Application Fields

- Petroleum petrochemical industry: Pipeline systems for crude oil, refined oil, chemical intermediates

- Water treatment industry: Water supply, sewage treatment, desalination equipment

- Power generation industry: Steam cooling water pipelines in thermal power plants

- Chemical industry: Transportation of corrosive acids, alkalis, organic solvents

- Municipal engineering: Urban gas supply heating pipelines

5. Installation Maintenance

- Installation Notes: Ensure the valve is installed in the correct flow direction (marked on the valve body); the pipeline should be clean free of impurities to avoid damaging the seal.

- Maintenance Requirements: Regularly check the sealing performance operation flexibility; replace the seal ring lubricate the valve stem periodically to extend service life. Avoid over-tightening the valve stem to prevent deformation.

6. Quality Assurance

All KHP Series Flanged Ball Valves undergo strict quality testing before leaving the factory, including pressure testing (shell test, seat test), leakage testing, operation test. They comply with international quality standards such as ISO 9001, API 6D, GB/T 12237, ensuring stable reliable performance in long-term use.

I can further adjust the terminology accuracy of this translation according to your specific industry standards (e.g., API, DIN) add technical parameter details of a certain KHP model. Do you need me to optimize a particular part of the content?

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!