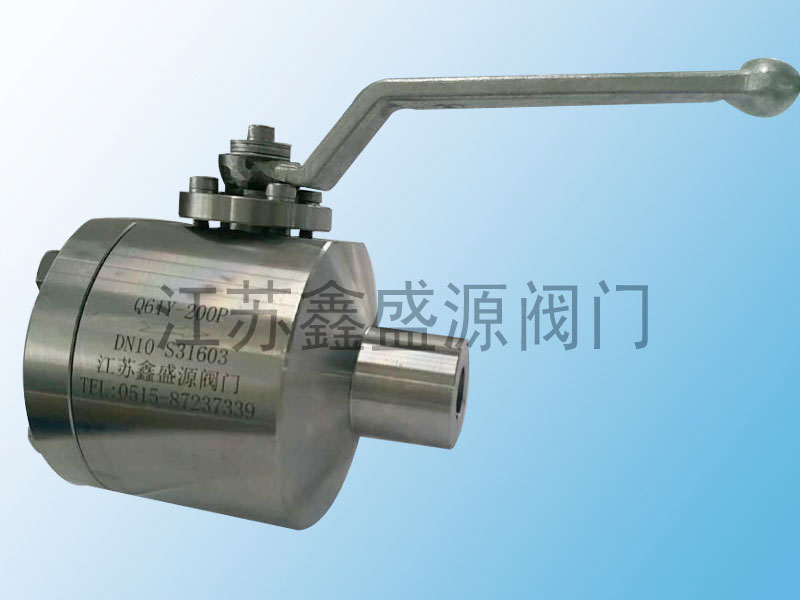

Q61Y硬密封高压球阀它具有旋转90度的动作,旋塞体为球体,有圆形通孔或通道通过其轴线。球阀在管路中主要用来做切断、分配和改变介质的流动方向,它只需要用旋转90度的操作和很小的转动力矩就能关闭严密。球阀适宜做开关、切断阀使用,但近来的发展已将球阀设计成使它具有节流和控制流量之用,如V型球阀。

Q61Y硬密封高压球阀的球体和阀座都是喷焊STL合金的,主体和附件也是锻造后再精加工,可以耐压42MPa,耐温630℃。可以安装气动 电动 液动等执行机构。Q61Y硬密封高压球阀本身结构紧凑,密封稳定,结构简单,维修方便,密封面与球面常在闭合状态,不易被介质冲蚀,易于操作和维修,适用于水、溶剂、酸和天然气等一般工作介质,而且还适用于工作条件恶劣的介质,如氧气、过氧化氢、甲烷和乙烯等,在各行业得到广泛的应用。球阀阀体可以是整体的,也可以是组合式的。

Q61Y硬密封高压球阀优点:

1.流体阻力小,全通径的球阀基本没有流阻。

2.结构简单、体积小、重量轻。

3.紧密度好。它有两个密封面,而且目前球阀的密封面材料广泛使用各种塑料,密封性好,能实现完全密封。在真空系统中也已广泛使用。

4.操作方便,开闭迅速,从全开到全关只要旋转90°,便于远距离的控制。

5.维修方便,球阀结构简单,密封圈一般都是活动的,拆卸更换都比较方便。

6.在全开或全闭时,球体和阀座的密封面与介质隔离,介质通过时,不会引起阀门密封面的侵蚀。

7.适用范围广,通径从小到几毫米,大到几米,从高真空至高压力都可应用。

8.由于球阀在启闭过程中有擦拭性,所以可用于带悬浮固体颗粒的介质中。

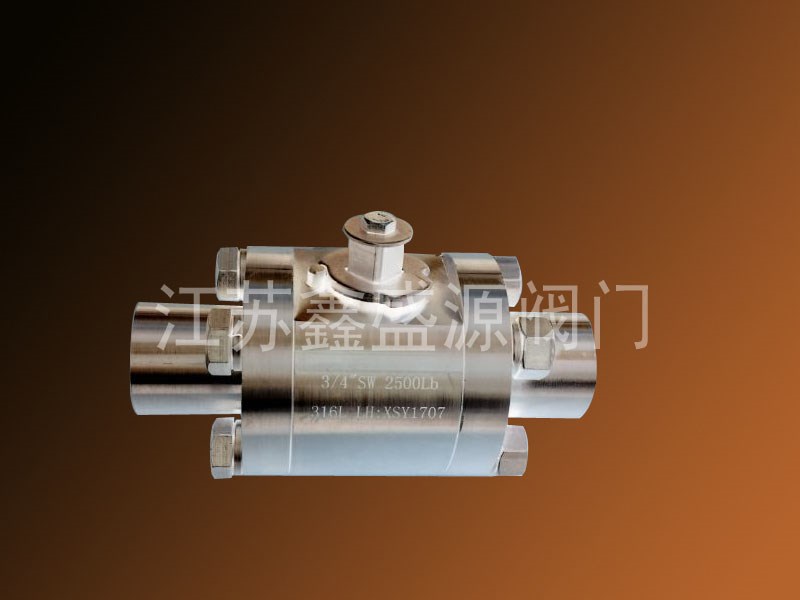

硬密封高压球阀

硬密封高压球阀是一种采用金属与金属密封结构的高压阀门,适用于高温、高压及含颗粒介质的严苛工况,凭借其优势耐压性、耐磨性和耐高温性,广泛应用于石油、化工、电力、冶金等行业的高压管道系统。

硬密封高压球阀- 结构特点:阀体、球体、阀座等核心部件多采用高强度合金钢材(如铬钼钢、不锈钢等),经锻造和精密加工而成,确保结构强度以承受高压;密封副采用金属硬密封设计(如球体与阀座均为金属材质),通过研磨形成紧密配合,具备良好的耐磨性和抗冲刷性;阀杆采用防吹出结构,配合高温高压填料,确保轴封;部分型号配备自润滑轴承,减少启闭摩擦,延长使用寿命。

硬密封高压球阀- 工作原理:通过旋转阀杆带动球体旋转90°实现启闭。当球体通孔与管道通道对齐时,阀门全开,介质流通;旋转90°后,球体与阀座的金属密封面紧密贴合,截断介质流动。硬密封结构在高压下可通过金属的弹性变形增强密封效果,适应高压差工况。

硬密封高压球阀- 性能优势:耐压能力强,公称压力通常可达PN16-PN420(或Class 150-Class 2500),能适应超高压管道系统;耐高温性能好,工作温度范围可达-29℃至600℃,适用于高温蒸汽、热油等介质;抗磨损、抗腐蚀,可输送含固体颗粒、粉尘等介质而不易损坏;密封性能稳定,长期使用后仍能保持稳妥密封,维护周期长。

硬密封高压球阀- 适用范围:适用于蒸汽、高温油、天然气、含颗粒浆液、腐蚀性气体等介质,公称通径一般为DN15-DN300。广泛应用于高压蒸汽管道、炼化装置、电厂锅炉系统、矿山冶金管道等,作为截断或控制设备使用。

Hard-seal high-pressure ball valve is a type of high-pressure valve with metal-to-metal sealing structure, suitable for harsh working conditions involving high temperature, high pressure, particle-containing media. With its excellent pressure resistance, wear resistance, high-temperature resistance, it is widely used in high-pressure pipeline systems in petroleum, chemical, electric power, metallurgy other industries.

Hard-seal high-pressure ball valve- Structural features: Core components such as valve body, ball, valve seat are mostly made of high-strength alloy steel (e.g., chrome-molybdenum steel, stainless steel, etc.), formed by forging precision machining to ensure structural strength for withstanding high pressure. The sealing pair adopts a metal hard-seal design (e.g., both ball valve seat are made of metal), forming a tight fit through grinding, with good wear resistance erosion resistance. The valve stem is equipped with a blow-out proof structure, combined with high-temperature high-pressure packing to ensure reliable shaft sealing. Some models are equipped with self-lubricating bearings to reduce opening-closing friction extend service life.

Hard-seal high-pressure ball valve- Working principle: The valve is opened closed by rotating the valve stem to drive the ball to rotate 90°. When the through-hole of the ball aligns with the pipeline channel, the valve is fully open, allowing medium flow; after rotating 90°, the metal sealing surfaces of the ball valve seat fit tightly to cut off medium flow. The hard-seal structure can enhance sealing effect through elastic deformation of metal under high pressure, adapting to high-pressure difference conditions.

Hard-seal high-pressure ball valve- Performance advantages: It has strong pressure resistance, with a nominal pressure usually up to PN16-PN420 ( Class 150-Class 2500), suitable for ultra-high pressure pipeline systems; it has excellent high-temperature resistance, with a working temperature range of -29℃ to 600℃, applicable to high-temperature steam, hot oil other media; it is wear-resistant corrosion-resistant, capable of conveying media containing solid particles dust without easy damage; the sealing performance is stable, maintaining reliable sealing after long-term use, with a long maintenance cycle.

Hard-seal high-pressure ball valve- Scope of application: Suitable for media such as steam, high-temperature oil, natural gas, particle-containing slurry, corrosive gas, with a nominal diameter generally of DN15-DN300. It is widely used in high-pressure steam pipelines, refining chemical plants, power plant boiler systems, mining metallurgy pipelines, etc., as a shut-off control device.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!