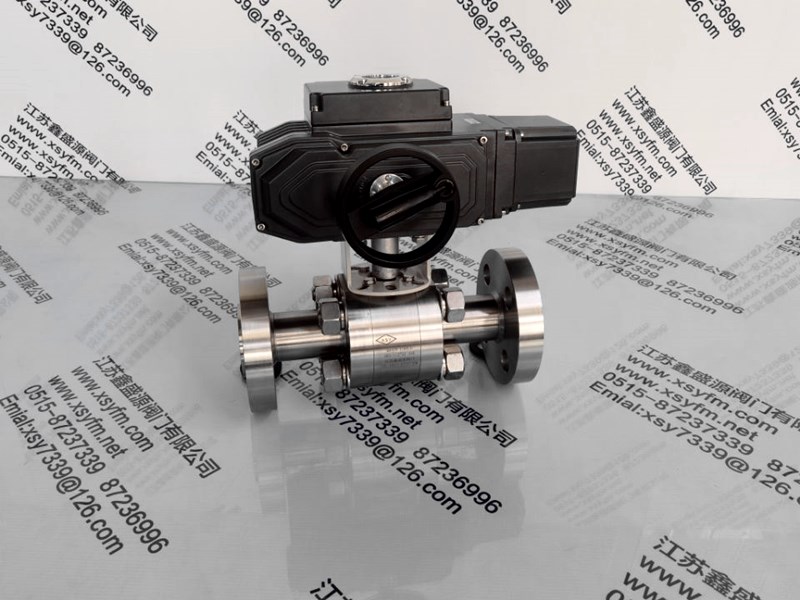

高压电动法兰球阀产品概述

高压电动法兰球阀是一种采用高性能电动执行机构驱动的高压管路控制装置,通过法兰端面连接方式实现管道系统的密封与流体控制。该产品采用精密加工的球体旋转结构,执行90°直角行程动作,专为石油天然气、化工、电力等工业领域的高压工况(PN16~PN420/Class 150~2500)设计。

高压电动法兰球阀核心技术特征:

超高压耐受性

阀体采用整体锻造工艺(ASTM A105/F316L等材料)

压力等级覆盖ANSI Class 150~2500(限42MPa)

符合API 6D、ASME B16.34等标准

高压电动法兰球阀零泄漏密封系统

球体表面超音速喷涂碳化钨(HVOF工艺)

双向金属密封结构(DBB设计)

密封等级达到API 598 VI级标准

高压电动法兰球阀智能驱动配置

一体化防爆电动执行器(Ex dⅡCT6/IP68)

支持Profibus-DP/Modbus RTU通讯协议

可选配智能定位器(定位精度±0.1%)

高压电动法兰球阀优化机械结构

低扭矩三体式阀体设计(比传统结构降低40%扭矩)

自润滑轴承系统(免维护周期达10,000次)

防火安全结构符合API 607/6FA标准

高压电动法兰球阀安全控制功能

ESD紧急切断响应时间<1秒

故障安全模式(FO/FC可选)

SIL2功能安全认证

中文术语英文对应整体锻造阀体Monoblock forged body超音速喷涂HVOF coating双向截断排放Double Block & Bleed (DBB)故障安全模式Fail-Safe (FO/FC)防火安全设计Fire-safe design智能定位器Smart positioner

备注:可根据具体项目要求补充NACE MR0175抗硫腐蚀认证、ISO 15848微泄漏测试等特殊标准。

High-Pressure Electric Flanged Ball Valve Product Overview

The high-pressure electric flanged ball valve is an advanced pipeline control device featuring motorized actuation flanged end connections, specifically engineered for critical high-pressure applications (PN16~PN420/Class 150~2500) in oil & gas, chemical power industries. Its precision-machined ball rotating mechanism performs 90° quarter-turn operation to ensure reliable fluid control.

Core Technical Features

Ultra-High Pressure Resistance

Monoblock forged body (ASTM A105/F316L materials)

Pressure ratings covering ANSI Class 150~2500 (up to 42MPa)

Compliant with API 6D, ASME B16.34 standards

Zero-Leakage Sealing System

Tungsten carbide coated ball (HVOF technology)

Double block & bleed (DBB) metal sealing

Meets API 598 VI class sealing standard

Smart Actuation Solution

Integrated explosion-proof actuator (Ex dⅡCT6/IP68)

Profibus-DP/Modbus RTU communication protocols

Optional smart positioner (±0.1% accuracy)

Optimized Mechanical Design

Low-torque trunnion-mounted structure (40% torque reduction)

Self-lubricating bearing system (10,000 cycles maintenance-free)

Fire-safe design per API 607/6FA

Safety Control Functions

ESD emergency shutdown (<1s response)

Fail-safe modes (FO/FC optional)

SIL2 functional safety certification

Key Technical Terms

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!