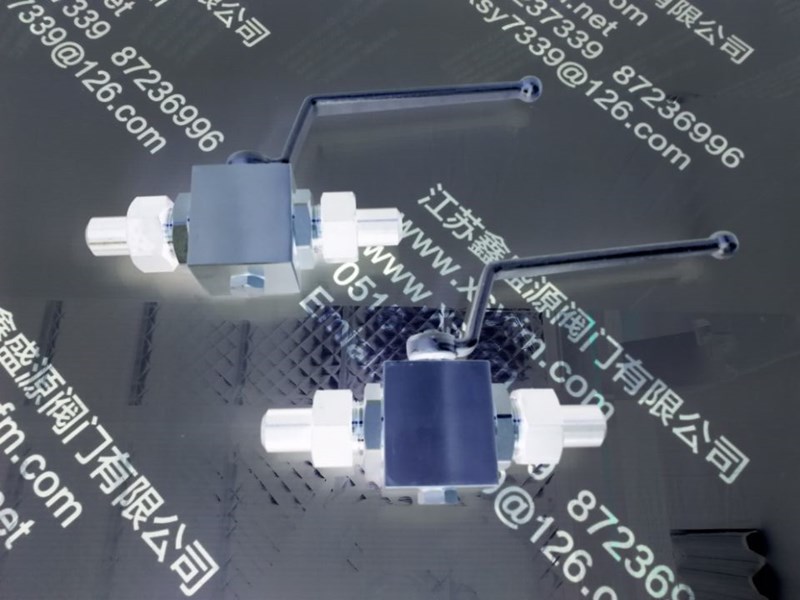

Q27Y固定式焊接球阀的球和阀座都是通过喷焊STL合金后进行配合研磨。可以耐高温到650℃,高压42MPa,可以通过颗粒状介质。它具有旋转90度的动作,旋塞体为球体,有圆形通孔或通道通过其轴线。球阀在管路中主要用来做切断、分配和改变介质的流动方向,它只需要用旋转90度的操作和很小的转动力矩就能关闭严密。球阀适宜做开关、切断阀使用,但近来的发展已将球阀设计成使它具有节流和控制流量之用,如V型球阀。

Q27Y固定式焊接球阀的主要特点是结构紧凑,密封稳定,结构简单,维修方便,密封面与球面常在闭合状态,不易被介质冲蚀,易于操作和维修,适用于水、溶剂、酸和天然气等一般工作介质,而且还适用于工作条件恶劣的介质,如氧气、过氧化氢、甲烷和乙烯等,在各行业得到广泛的应用。球阀阀体可以是整体的,也可以是组合式的。

Q27Y固定式焊接球阀优点:

1.流体阻力小,全通径的球阀基本没有流阻。

2.结构简单、体积小、重量轻。耐高温 耐高压 方便安装执行机构。

3.紧密稳定。它有两个密封面,而且目前球阀的密封面材料广泛使用各种塑料,密封性好,能实现完全密封。在真空系统中也已广泛使用。

4.操作方便,开闭迅速,从全开到全关只要旋转90°,便于远距离的控制。

5.维修方便,球阀结构简单,密封圈一般都是活动的,拆卸更换都比较方便。

6.在全开或全闭时,球体和阀座的密封面与介质隔离,介质通过时,不会引起阀门密封面的侵蚀。

7.适用范围广,通径从小到几毫米,大到几米,从高真空至高压力都可应用。

8.由于球阀在启闭过程中有擦拭性,所以可用于带悬浮固体颗粒的介质中。

固定式焊接球阀产品概述

固定式焊接球阀是一种球体位置固定且采用焊接连接方式的球阀,通过阀体两端与管道焊接相连,具有结构稳固、密封稳定的特点,适用于高压、高流速等对连接强度和密封性要求较高的工况。以下是其产品概述:

固定式焊接球阀- 结构组成:主要由阀体、固定球体、阀座、阀杆、焊接端及执行机构(手动、电动、气动等)组成。球体与阀杆连接牢固,工作时仅做旋转运动而无轴向位移,确保密封稳定性;阀体两端为焊接端,可与管道直接焊接,减少连接松动风险。

固定式焊接球阀- 工作原理:通过旋转阀杆带动球体旋转90度实现启闭。开启时,球体通孔与管道通道对齐,介质流通;关闭时,球体阻断通道,利用阀座与球体的紧密贴合形成密封,防止介质泄漏。

固定式焊接球阀- 特点优势:焊接连接强度高、密封性好,抗振动和抗冲击能力强,适用于高压、易燃易爆等严苛工况;球体固定设计减少密封面磨损,延长使用寿命;结构紧凑,流阻小,操作简便且启闭迅速;材质多选用碳钢、不锈钢等,耐腐蚀性和耐高温性较好。

固定式焊接球阀- 技术参数:公称通径常见DN15-DN300等规格,公称压力一般为PN16-PN250,适用温度范围根据材质不同约为-20℃至425℃(碳钢)或-196℃至540℃(不锈钢)。

固定式焊接球阀- 应用领域:广泛应用于石油化工、天然气输送、电力、冶金等行业,用于控制原油、天然气、蒸汽、高温油品等介质的通断。

The fixed welded ball valve is a type of ball valve with a fixed ball position welded connection. It is connected to pipelines by welding at both ends of the valve body, featuring a stable structure reliable sealing performance, suitable for working conditions with high requirements for connection strength tightness, such as high pressure high flow rate. The product overview is as follows:

The fixed welded ball- Structural composition: It mainly consists of a valve body, a fixed ball, a valve seat, a valve stem, welded ends an actuator (manual, electric, pneumatic, etc.). The ball is firmly connected to the valve stem, only rotates without axial displacement during operation, ensuring sealing stability; both ends of the valve body are welded ends, which can be directly welded to the pipeline to reduce the risk of connection loosening.

The fixed welded ball- Working principle: The valve is opened closed by rotating the valve stem to drive the ball to rotate 90 degrees. When opened, the through-hole of the ball is aligned with the pipeline channel, allowing medium to flow; when closed, the ball blocks the channel, a seal is formed by the close fit between the valve seat the ball to prevent medium leakage.

The fixed welded ball- Features advantages: The welded connection has high strength good sealing performance, with strong resistance to vibration impact, suitable for harsh working conditions such as high pressure, flammable explosive environments; the fixed ball design reduces wear on the sealing surface prolongs service life; it has a compact structure, low flow resistance, simple operation quick opening closing; materials such as carbon steel stainless steel are mostly used, with good corrosion resistance high temperature resistance.

The fixed welded ball- Technical parameters: The nominal diameter commonly includes specifications such as DN15-DN300; the nominal pressure is generally PN16-PN250; the applicable temperature range varies by material, approximately -20℃ to 425℃ (carbon steel) -196℃ to 540℃ (stainless steel).

The fixed welded ball- Application fields: Widely used in petrochemical, natural gas transmission, electric power, metallurgy other industries, for controlling the on-off of media such as crude oil, natural gas, steam, high-temperature oil products.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!