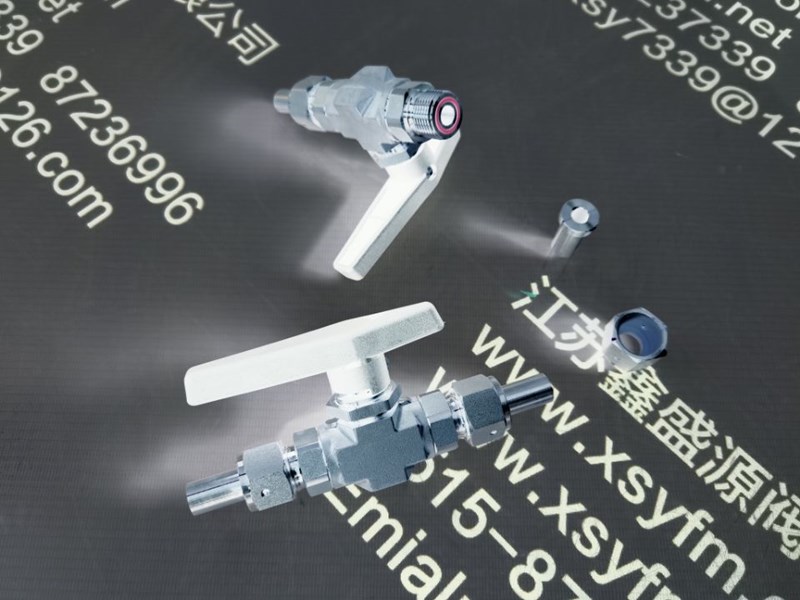

VCO外螺纹焊接球阀也叫活接式球阀,两端带活接连接方式,带焊接短管,主要为外螺纹式,它具有旋转90度的动作,旋塞体为球体,有圆形通孔或通道通过其轴线。球阀在管路中主要用来做切断、分配和改变介质的流动方向,它只需要用旋转90度的操作和很小的转动力矩就能关闭严密。球阀适宜做开关、切断阀使用,但近来的发展已将球阀设计成使它具有节流和控制流量之用,如V型球阀。

VCO外螺纹焊接球阀本身结构紧凑,密封,结构简单,维修方便,密封面与球面常在闭合状态,不易被介质冲蚀,易于操作和维修,适用于水、溶剂、酸和天然气等一般工作介质,而且还适用于工作条件恶劣的介质,如氧气、过氧化氢、甲烷和乙烯等,在各行业得到广泛的应用。球阀阀体可以是整体的,也可以是组合式的。

Q21F外螺纹焊接球阀优点:

1.流体阻力小,全通径的球阀基本没有流阻。

2.结构简单、体积小、重量轻。

3.紧密完好。它有两个密封面,而且目前球阀的密封面材料广泛使用各种塑料,密封性好,能实现完全密封。在真空系统中也已广泛使用。

4.操作方便,开闭迅速,从全开到全关只要旋转90°,便于远距离的控制。

5.维修方便,球阀结构简单,密封圈一般都是活动的,拆卸更换都比较方便。

6.在全开或全闭时,球体和阀座的密封面与介质隔离,介质通过时,不会引起阀门密封面的侵蚀。

7.适用范围广,通径从小到几毫米,大到几米,从高真空至高压力都可应用。

8.由于球阀在启闭过程中有擦拭性,所以可用于带悬浮固体颗粒的介质中。

焊接球阀产品概述

VCO焊接球阀是一种采用焊接方式连接,具有高密封性能和稳定性的阀门,常用于对流体控制有较高要求的管道系统。

VCO焊接球阀- 连接方式:采用焊接连接,将阀体与管道焊接为一体,有效阻断介质向环境泄漏的通道,减少外漏点,提高使用稳定性 。

VCO焊接球阀- 结构特点:通常为整体式焊接结构,阀体由板材锻压后焊接而成或采用碳钢无缝钢管压制成型,结构紧凑,体积小、重量轻。阀杆多采用不锈钢材质,具有良好的耐腐蚀性。球体加工精度高,有计算机检测仪跟踪检测,操作轻便,无不良干涉 。

VCO焊接球阀- 密封性能:阀座一般由PTFE密封环及弹簧组成,对压力和温度的变化适应能力强,可实现零泄漏。阀杆底部有PTFE自封密封垫和O型密封圈,上面也有O型密封圈和PTFE密封垫,进一步确保无泄漏 。

VCO焊接球阀- 驱动方式:可采用手柄、涡轮、气动、电动等传动结构,开关灵活轻便,能满足不同工况的控制要求 。

VCO焊接球阀- 性能优势:流体阻力小,能承受较高压力,抗外力安全性能好。阀体材料与管道材质相同,不会出现应力不均,不易因地震或车辆经过地面而变形,管道耐老化 。

VCO焊接球阀- 应用领域:广泛应用于城市燃气、城市供热、石油化工、造船、钢铁、调压站、发电厂等各类管道设备上,尤其适用于含硫化氢等腐蚀严重的天然气长输管线及埋地管线 。

VCO welding ball - valve is a kind of valve that adopts welding connection, featuring high - sealing performance reliable stability, which is often used in pipeline systems with high - requirements for fluid control. The product overview is as follows:

VCO welding ball - valve is- Connection mode: It adopts welding connection, welding the valve body the pipeline into one, effectively blocking the passage of medium leakage to the environment, reducing external leakage points improving the use reliability .

VCO welding ball - valve is- Structural features: Usually, it has an integral welding structure. The valve body is welded after being forged sheet metal formed by pressing carbon steel seamless steel pipes, with a compact structure, small volume light weight. The valve stem is mostly made of stainless - steel, which has good corrosion resistance. The ball has a high - processing accuracy, is tracked detected by an advanced computer detector, so it is easy to operate without poor interference .

VCO welding ball - valve is- Sealing performance: The valve seat is generally composed of a PSeE sealing ring a spring, which has a strong adaptability to pressure temperature changes, can achieve zero leakage. There is a PTFE self - sealing gasket an O - ring at the bottom of the valve stem, there are also O - rings PTFE gaskets on the top, further ensuring no leakage .

VCO welding ball - valve is- Driving mode: It can adopt driving structures such as handles, turbines, pneumatics electrics, with flexible light - weight switching, which can meet the control requirements of different working conditions .

VCO welding ball - valve is- Performance advantages: It has small fluid resistance, can bear high pressure, has good safety performance against external forces. The material of the valve body is the same as that of the pipeline, so there will be no uneven stress, it is easy to deform due to earthquakes vehicles passing through the ground, the pipeline is resistant to aging .

VCO welding ball - valve is- Application fields: It is widely used in various pipeline equipment such as urban gas, urban heating, petro - chemical, ship - building, steel, pressure - regulating stations power plants, especially suitable for natural gas long - distance transmission pipelines with serious corrosion such as hydrogen sulfide buried pipelines.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!