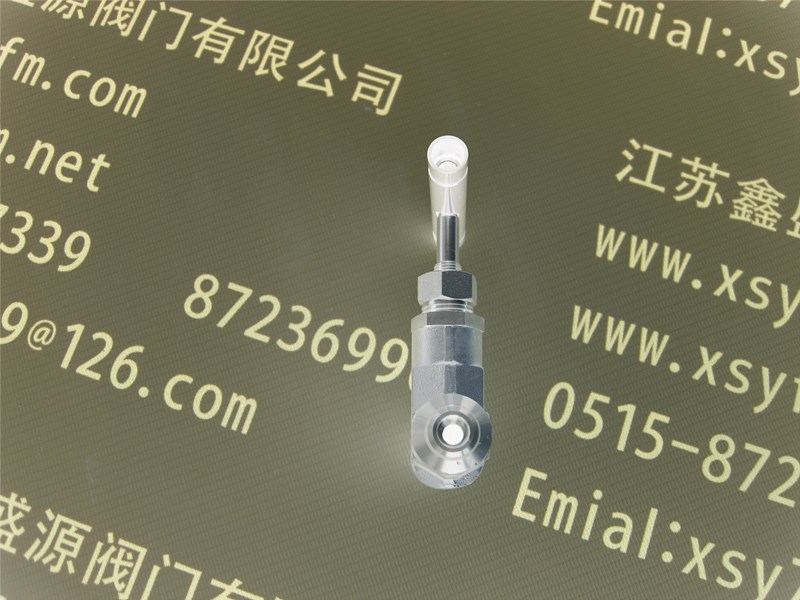

产品名称:模锻对焊针型阀

产品型号:J61Y

工作压力:3000PSI~6000PSI(413bar),高可达10000PSI(689bar)

工作温度:

PTFE填料:-38oC 至 180oC (-100oF 至 356oF)

PPL 填料:-38oC 至 280oC (-100oF 至 536oF)

石墨填料:-24oC 至 480oC (-75oF 至 896oF)

连接端口:进口螺纹:PZ27.8 出口螺纹:G5/8

适用介质:氧气、空气、氮气

鑫盛源模锻对焊针型阀优点:

1、两截阀杆设计,上阀杆螺纹淡化工艺处理

2、下阀杆表经经滚压硬化处理上阀杆螺纹的润滑脂与系统介质隔离

3、无旋转的下阀杆垂直运动代替旋转升降,减少阀杆行程对填料的磨擦,手感更轻便

4、阀门在全开位置具有背密封功能

5、可选面板安装

6、可安装手柄或者手轮操作,稳固耐用多种颜色手柄可供选择

7、每只阀门在出厂前均按设计压力的1.1倍进行氮气密封测试,并按额定工作压力的1.5倍水压进行壳体强度测试

模锻对焊针形阀

模锻对焊针形阀是一种采用一体式模锻工艺制造的高压阀门,具有结构紧凑、耐高压、密封性能好的特点。其阀体通过锻造工艺成型,避免了铸造缺陷,提升了承压能力和安全性,适用于高温、高压及腐蚀性流体控制场合,广泛应用于石油、化工、电站、实验室气体管路等领域2。

该类阀门通常采用手动驱动,连接方式为对焊(Butt Weld),可与管道直接焊接,确保无泄漏连接。阀杆设计为非旋转式升降结构,减少填料磨损,延长使用寿命。密封材料可选PTFE、柔性石墨等,适应不同介质和温度要求。主流材质包括不锈钢(如SS304、SS316)、合金钢等,工作压力可达6000 psi以上,部分型号可达80000 psi2。

英文翻译(Product Overview in English)

A forged butt-weld needle valve is a high-pressure valve manufactured using an integral forging process, featuring compact structure, high pressure resistance, excellent sealing performance. The body is formed through precision forging, eliminating casting defects enhancing structural integrity safety. It is suitable for high-temperature, high-pressure, corrosive fluid control applications, widely used in oil & gas, chemical plants, power stations, laboratory gas piping, instrumentation systems.2

Typically operated manually, the valve connects to pipelines via butt welding, ensuring a leak-tight joint. The non-rotating stem design reduces packing wear extends service life. Seal materials such as PTFE flexible graphite are available to suit various media temperature ranges. Common body materials include stainless steel (e.g., SS304, SS316) alloy steels, with working pressures up to 6000 psi higher (some models up to 80,000 psi).2

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!