J44Y/L44Y法兰角式截止阀/截流阀属于强制密封式阀门,所以在阀门关闭时,必须向阀瓣施加压力,以强制密封面不泄漏。当介质由阀瓣下方进入阀门时,操作力所需要克服的阻力,是阀杆和填料的摩擦力与由介质的压力所产生的推力,关阀门的力比开阀门的力大,所以阀杆的直径要大,否则会发生阀杆顶弯的故障。近年来,从自密封的阀门出现后,截止阀的介质流向就改由阀瓣上方进入阀腔,这时在介质压力作用下,关阀门的力小,而开阀门的力大,阀杆的直径可以相应地减少。同时,在介质作用下,这种形式的阀门也较严密。我国阀门“三化给”曾规定,截止阀的流向,一律采用自上而下。

法兰角式截止阀/截流阀设计与制造标准:

设计与制造:GB12233

法兰尺寸:GB9113

结构长度:GB12221

检验与实验:GB/T13927性能与规范

法兰角式截止阀/截流阀性能与规范:

| 公称压力 | 16 | 32 | Mpa |

| 壳体试验 | 24 | 48 | |

| 密封试验 | 17.6 | 35.2 | |

| 气密封试验 | 0.5-0.7 | ||

| 适用介质 | C | P | R |

| 水、油品、蒸汽 | 氮氢混合气 | 碱液、液氨 | |

| 适用温度(℃) | ≤200 | ||

法兰角式截止阀/截流阀主要连接与外形尺寸:

| 型 号 | 通径 DN(mm) | 主要连接尺寸 | 外形尺寸 | ||||||||

| L | D | D1 | M | D2 | b | Z-фd | LO | H | H1 | ||

| AJ44H-320 AL44H-320 | 3 | 60 | 70 | 42 | M14×1.5 | 10 | 15 | 3-16 | 100 | 71 | 77 |

| 6 | 60 | 70 | 42 | M14×1.5 | 10 | 15 | 3-16 | 150 | 80 | 94 | |

| J44Y-160 L44Y-160 | 10 | 90 | 95 | 60 | M24×2 | 10 | 20 | 3-18 | 200 | 260 | 275 |

| 15 | 105 | 95 | 60 | M24×2 | 16 | 20 | 3-18 | 200 | 268 | 288 | |

| J44Y-320 L44Y-320 | 10 | 90 | 95 | 60 | M24×2 | 10 | 20 | 3-18 | 200 | 268 | 275 |

| 15 | 105 | 105 | 68 | M33×2 | 17 | 20 | 3-18 | 200 | 268 | 288 | |

| J44Y-160 L44Y-160 | 25 | 120 | 102 | 68 | M33×2 | 28 | 20 | 3-18 | 300 | 225 | 245 |

| 32 | 135 | 115 | 80 | M42×2 | 37 | 22 | 4-18 | 300 | 222 | 248 | |

| 40 | 165 | 165 | 115 | M52×2 | 47 | 28 | 6-26 | 350 | 265 | 300 | |

| 50 | 190 | 165 | 115 | M64×3 | 59 | 32 | 6-26 | 400 | 303 | 345 | |

| J44Y-320 L44Y-320 | 25 | 120 | 115 | 80 | M42×2 | 35 | 22 | 4-18 | 300 | 225 | 245 |

| 32 | 135 | 135 | 95 | M48×2 | 41 | 25 | 4-22 | 300 | 222 | 248 | |

| 40 | 165 | 165 | 115 | M64×3 | 58 | 32 | 6-26 | 350 | 265 | 300 | |

| 50 | 190 | 200 | 145 | M80×3 | 70 | 40 | 6-29 | 400 | 303 | 345 | |

| GJ44H-160 GL44H-160 | 65 | 215 | 200 | 145 | M80×3 | 73 | 40 | 6-29 | 710 | 430 | 490 |

| 80 | 260 | 225 | 170 | M100×3 | 93 | 50 | 6-33 | 810 | 520 | 600 | |

| 100 | 290 | 260 | 195 | M125×4 | 115 | 60 | 6-36 | 850 | 595 | 685 | |

| GJ44H-320 GHJ44H-320 | 65 | 215 | 225 | 170 | M100×3 | 90 | 50 | 6-33 | 710 | 430 | 490 |

| 80 | 260 | 260 | 195 | M125×4 | 112 | 60 | 6-36 | 810 | 520 | 600 | |

| 100 | 290 | 300 | 235 | M155×4 | 130 | 75 | 8-39 | 850 | 595 | 285 | |

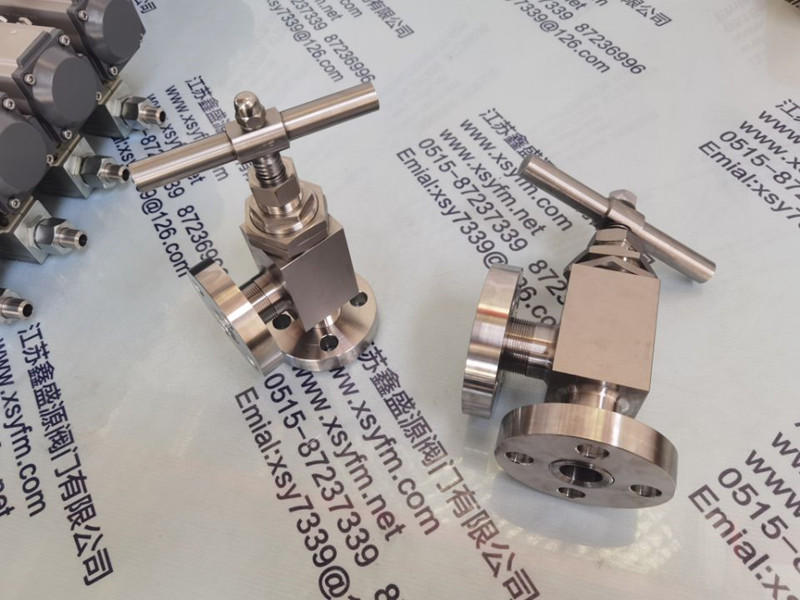

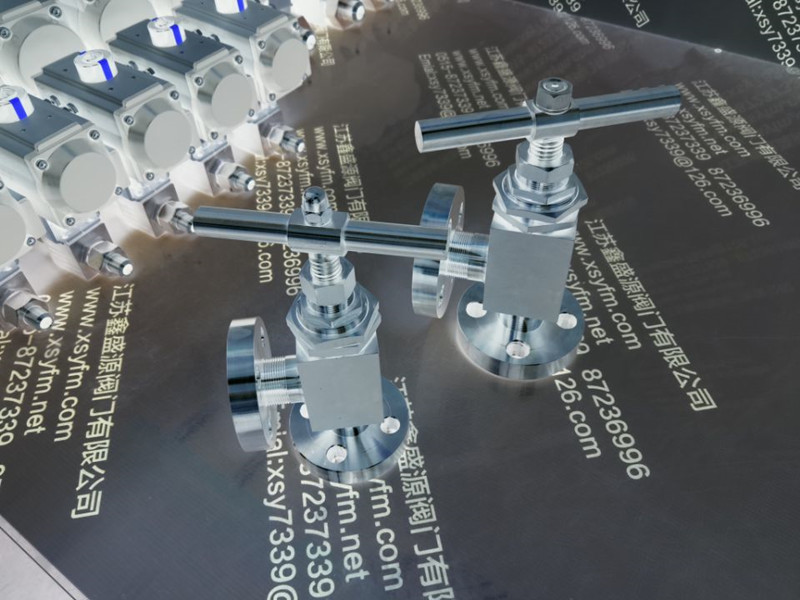

法兰角式截止阀 / 法兰角式节流阀

法兰角式截止阀和节流阀是一种采用角式流道(进口与出口成90°直角)和法兰连接方式的阀门。其核心区别在于阀瓣(关闭件)的设计:截止阀主要用于稳定的切断或接通流体,要求严格的密封性;而节流阀主要用于调节流量或压力,要求阀瓣能对流量进行精准且平稳的控制。

法兰角式截止阀和节流阀其核心设计特点和关键技术包括:

角式流道设计 (Angular Flow Path): 与直通式截止阀不同,角式阀门的进口与出口管道成90°直角。这种设计允许流体方向实现90°的自然改变,能有效降低流阻系数(流阻较直通式小),减少对阀内件的直接冲刷,特别适用于节流工况。同时,它可以直接安装在管道的弯头处,节省安装空间和管道配件。

截止与节流功能 (Shut-off & Throttling):

截止阀 (Globe Valve): 阀瓣通常为平顶或锥形设计,与阀座形成面密封或线密封,当阀门完全关闭时,能实现良好的密封和极低的泄漏率。

节流阀 (Throttle Valve): 阀瓣设计呈抛物线、针形或窗形等特殊形状,其特点是开启过程平稳,能够对流量进行精细、准确的线性调节,避免高速流体对密封面的气蚀和冲蚀。

法兰连接 (Flanged Connection): 阀体两端带有标准法兰面,通过螺栓与管道法兰连接。这种连接方式结构坚固、密封稳定、可承受高压力,便于阀门的安装、拆卸和维护,是中高压管道系统的首选连接方式。

法兰角式截止阀和节流阀阀瓣与阀杆结构: 阀瓣通常与阀杆采用活动连接(如T形头),称为旋转阀杆式。此设计使得阀瓣在关闭过程中能自动调整位置,与阀座实现最佳吻合,确保密封效果,同时减少磨损。

法兰角式截止阀和节流阀应用领域:

广泛应用于石油、化工、电力、制药、水处理等行业的管道系统中,特别适用于:

角式截止阀: 需要稳定切断的场合,如锅炉给水、蒸汽系统、高压流体。

角式节流阀: 需要精准调节流量或压力的场合,如冷却水调节、锅炉排污、减压装置。

法兰角式截止阀和节流阀核心价值:

提供了一种既能改变流体方向,又能实现稳定切断或精准调节的高效阀门解决方案,兼具低流阻、高密封性和调节精度的特点。

Product Name: Flanged Angle Globe Valve / Flanged Angle Throttle Valve

Product Overview:

The Flanged Angle Globe Valve Flanged Angle Throttle Valve are types of valves featuring an angular flow path (inlet outlet are oriented at a 90-degree angle) flanged connections. The core difference lies in the design of the disc (closure member): The Globe Valve is primarily used for reliable shut-off on/off service, requiring tight sealing, while the Throttle Valve is designed for flow pressure regulation, requiring the disc to provide precise smooth control of flow rate.

Their core design features key technologies include:

Angular Flow Path Design: Unlike straight-through globe valves, the angle valve's inlet outlet pipes are at a 90-degree right angle. This design allows for a natural 90-degree change in fluid direction, effectively reducing the flow resistance coefficient (lower than straight-through type) minimizing direct impingement on the trim. It is particularly suitable for throttling services. Additionally, it can be installed directly at a pipeline elbow, saving installation space pipe fittings.

Shut-off & Throttling Function:

Globe Valve: The disc is typically flat-faced conical, forming a surface line seal with the seat. When fully closed, it achieves excellent sealing very low leakage rates.

Throttle Valve: The disc is designed with a special shape, such as parabolic, needle, characterized (cage). It features a smooth opening process, enabling fine accurate linear modulation of flow rate, helps avoid cavitation erosion of the sealing surfaces by high-velocity fluid.

Flanged Connection: The valve body has standard flanges at both ends, connected to the pipeline flanges via bolts. This connection method offers robust structure, reliable sealing, high-pressure capability. It facilitates easy installation, removal, maintenance of the valve, making it the preferred connection method for medium high-pressure piping systems.

Disc Stem Structure: The disc is often connected to the stem with a movable joint (e.g., a T-head), known as a non-rotating stem design. This allows the disc to self-align with the seat during the closing operation, ensuring optimal sealing contact reducing wear.

Applications:

Widely used in piping systems across industries such as oil & gas, chemical, power generation, pharmaceuticals, water treatment. Particularly suitable for:

Angle Globe Valve: Applications requiring reliable shut-off, e.g., boiler feedwater, steam systems, high-pressure fluids.

Angle Throttle Valve: Applications requiring precise flow pressure regulation, e.g., cooling water control, boiler blowdown, pressure reduction devices.

Core Value:

It provides an efficient valve solution that combines the ability to change flow direction with reliable shut-off precise regulation, featuring low flow resistance, high sealing integrity, control accuracy.

关键术语翻译 (Key Term Translation)

法兰角式截止阀: Flanged Angle Globe Valve

法兰角式节流阀: Flanged Angle Throttle Valve

角式流道: Angular Flow Path

阀瓣: Disc

阀座: Seat

节流: Throttling / Regulation

调节: Modulation / Control

流量: Flow Rate

法兰连接: Flanged Connection

旋转阀杆式: Non-rotating Stem (或 Rising Stem with Non-rotating Disc)

密封面: Sealing Surface / Face

流阻: Flow Resistance

气蚀: Cavitation

冲蚀: Erosion

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!