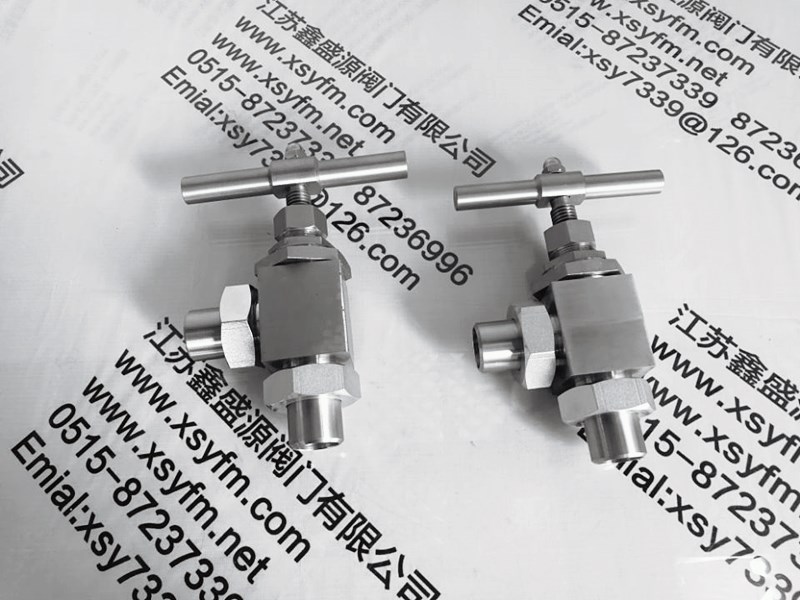

角式焊接截止阀

角式焊接截止阀(Angle Pattern Welding Stop Valve)是一种采用角式结构设计的截止阀,阀体进出口呈90°直角,适用于管道方向需要改变的工况。其阀体与管道采用焊接连接(对焊或承插焊),具有密封性好、耐高压、耐高温等特点,广泛应用于石油、化工、电力、制药等行业的高压管路系统。

角式焊接截止阀主要特点:

角式结构:进出口呈90°直角,便于管道转向安装,节省空间。

焊接连接:采用对焊(BW)或承插焊(SW),确保高强度密封,适用于高压、高温工况。

角式焊接截止阀密封稳定:阀瓣与阀座采用硬质合金或金属密封,耐磨损,使用寿命长。

角式焊接截止阀低流阻设计:优化流道结构,减少介质流动阻力。

适用介质:水、蒸汽、油品、腐蚀性气体/液体等。

角式焊接截止阀典型结构:

阀体、阀盖、阀瓣、阀杆、密封圈(石墨/PTFE)、手轮/执行机构等。

注:可根据具体标准(如API、ASME)补充技术参数(压力等级、材质等)。

Angle Pattern Welding Stop Valve is a type of globe valve with a 90° angled body design, suitable for pipeline systems requiring directional changes. It features welded connections (Butt Welding Socket Welding) for high-pressure high-temperature applications, widely used in petroleum, chemical, power, pharmaceutical industries.

Key Features:

Angular Design: 90° inlet outlet for compact pipeline routing.

Welded Connection: Butt Weld (BW) Socket Weld (SW) ensures leak-proof performance under extreme conditions.

Reliable Sealing: Hardened metal alloy seat/disc for wear resistance long service life.

Low Flow Resistance: Optimized flow path reduces pressure drop.

Compatible Media: Water, steam, oil, corrosive gases/liquids, etc.

Typical Structure:

Valve body, bonnet, disc, stem, sealing ring (graphite/PTFE), handwheel/actuator, etc.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!