Parker拖车内丝球阀球体处特殊密封(防止内漏):

阀座填料:聚甲醛密封,很好的承受高压性能,为适应低温恶劣天气,可在聚甲醛中加入一定比例二氧化锰,可使温度范围达到 -40℃~+200℃。

防腐蚀金属保护圈:在压缩气体行业,阀门在开启时压力非常高,尤其是压缩天然气,通常都含有杂质(天然气在过滤后,杂质含量依然偏高),气体在球阀流通的过程中,在高压的作用下,气体温度会快速升高使聚甲醛阀体密封变软,这使气体中的杂质在高压的冲击下,很容易在通过阀体密封时,划伤密封,并造成气体泄漏。

所以聚甲醛密封加上防腐蚀金属保护圈的特殊设计,能使在以上情况出现时,避免了气体直接接触聚甲醛阀体密封(气体接触的是上面的金属密封),从而尽可能的促使球阀的密封效果,防止内漏情况出现。

Parker拖车内丝球阀阀杆处特殊密封(防止外漏):

主要应用于加气机行业,由于开关频率过高,一般至少为150-200次每天,普通的NBR,FPM,PTFE等密封不能达到要求,球阀寿命大大降低,采用特殊阀杆填料密封,使球阀可以达到至少20万次的使用寿命。气动球阀采用直接连接球阀和执行器装置的结构,通过特殊连接件连接,以减少磨擦力,从而达到延长球阀使用寿命的效果。

Parker拖车内丝球阀接头处特殊密封 (防止外漏):

由于CNG运输挂车的特殊应用,在工作过程中会伴随震动,球阀接头处的O型圈易被挤压而造成破损现象。原因为:球阀在受力的作用下,O型圈被挤压到球阀接头和阀体处的缝隙中,而发生变形,导致O型圈被损坏,球阀发生接头处外漏。

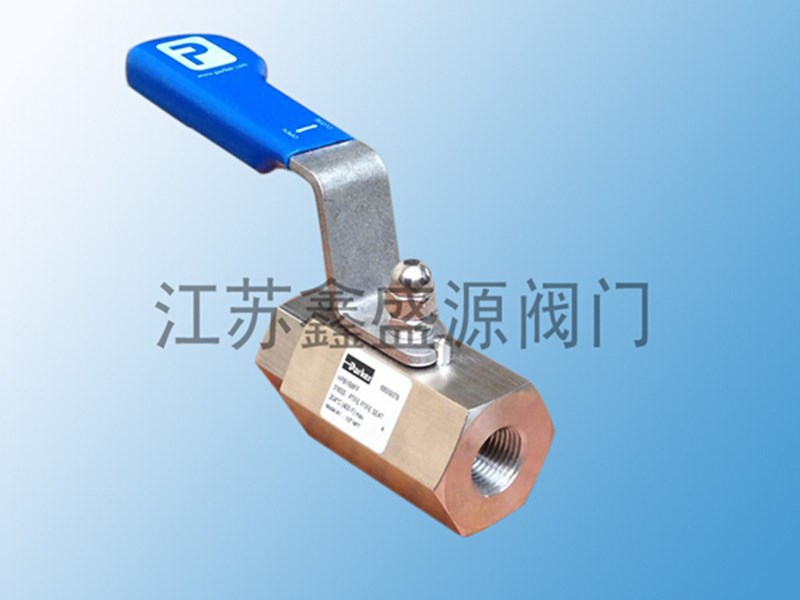

拖车内丝球阀

拖车内丝球阀是一种专为罐车、拖车、集装箱等移动式压力容器设计的管道控制阀门。其名称中的“内丝”指的是阀门的连接端为内螺纹(通常是NPT或BSP螺纹),这种设计便于与外部管道或软管接头进行快速、紧凑的连接,是槽车装卸环节的关键部件之一。

拖车内丝球阀主要特点:

内螺纹连接: 阀门端口加工有内螺纹,无需额外的法兰或外接接头,结构紧凑,连接方便快捷,非常适合空间有限的移动设备。

快速启闭: 采用球阀结构,只需将手柄旋转90度即可实现全开或全关,操作迅速,能有效满足槽车快速装卸的需求。

密封稳定: 阀座通常采用聚四氟乙烯(PTFE)、增强聚四氟乙烯(RPTFE)或尼龙等材料,确保阀门在输送石油、化工介质、液化气体等时具有很好的密封性能,防止泄漏。

结构坚固: 阀体多采用不锈钢(如304、316)、碳钢或 brass 等坚固材料制造,能够承受道路运输中的振动和冲击,并具有较高的耐压能力。

拖车内丝球阀防火安全设计: 许多高标准的内丝球阀采用防火结构设计。在发生火灾时,软密封阀座烧损后,金属阀座能与球体形成金属对金属的密封,从而阻止火灾蔓延。

操作方式多样: 除常见的手柄操作外,还可根据需求配备齿轮箱、气动或电动执行器,实现远程或自动化控制。

拖车内丝球阀应用领域:

主要用于石油化工、燃气、食品工业等领域中的罐式汽车、铁路罐车、可移动压力容器罐柜(ISO TANK)等设备上,作为流体(如燃油、化学品、液化气、食品原料)装载和卸载的开关控制阀。

Tank Trailer BSPP/NPT Female Thread Ball Valve Product Overview

A Tank Trailer Female Thread Ball Valve is a pipeline control valve specifically designed for mobile pressure vessels such as tank trucks, trailers, ISO containers. The term "female thread" in its name indicates that the valve's connection ends are internal threads (typically NPT BSPP threads). This design facilitates quick compact connection to external pipes hose fittings, making it a key component in the loading unloading process of tankers.

Key Features:

Female Threaded Connections: The valve ports are machined with internal threads, eliminating the need for additional flanges external adapters. This compact structure allows for convenient rapid connection, making it ideal for mobile equipment with limited space.

Quick Operation: Utilizing a ball valve design, it only requires a 90-degree turn of the handle to achieve full open full closed positions. This rapid operation efficiently meets the demands of fast loading unloading for tank trucks.

Reliable Sealing: The valve seats are typically made materials like PTFE, reinforced PTFE (RPTFE), nylon, ensuring excellent sealing performance when transporting petroleum, chemical media, liquefied gases, etc., preventing leaks.

Robust Construction: The valve body is often manufactured sturdy materials such as stainless steel (e.g., 304, 316), carbon steel, brass, enabling it to withstand vibrations impacts during road transport offering high pressure resistance.

Fire-Safe Design: Many high-standard female thread ball valves incorporate a fire-safe design. In the event of a fire, if the soft seal seat is damaged by flames, the metal seat can form a metal-to-metal seal with the ball, preventing the spread of fire.

Various Actuation Options: Besides common manual handle operation, they can be equipped with gear operators, pneumatic, electric actuators based on requirements to enable remote automated control.

Applications:

Primarily used on equipment such as tank trucks, railway tank cars, portable pressure container tanks (ISO Tanks) in the petrochemical, gas, food industries. It serves as an on/off control valve for loading unloading fluids (e.g., fuel, chemicals, liquefied gas, food ingredients).

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!