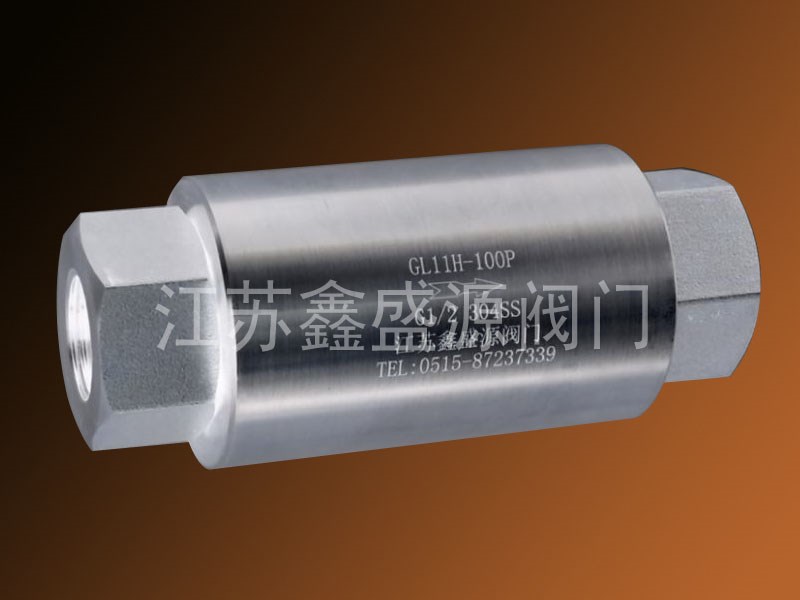

LNG低温高压过滤器是输送介质的管道系统不可缺少的一种过滤装置,通常安装在减压阀、泄压阀、定水位阀或其它设备的进口端,用来清除介质中的杂质,以保护阀门及设备的正常使用。

具有结构靠前,阻力小,排污方便等特点。

适用介质可为水、油、气。一般通水网为18~30目,通气网为10~100目,通油网为100~480目。

篮式过滤器主要由接管、主管、滤蓝、法兰、法兰盖及紧固件等组成。当液体通过主管进入滤篮后,固体杂质颗粒被阻挡在滤篮内,而洁净的流体通过滤篮、由过滤器出口排出。

广泛用于LNG CNG设备入口段过滤,后端设备使用寿命,适用液化气、天然气、空气等介质。

LNG CNG低温高压过滤器说明

1.适用于压缩天然气系统高压过滤单元;

2.过滤高、流通能力大、结构紧凑;

3.流通能力大,始于200-2500方CNG减压撬;

4.结构简单,可在线维修;

5.流通能力大,结构紧凑;密封严密,无气体渗漏;

6.安装省力,经济实惠;

7.连接方式:螺纹连接 对焊连接 插焊连接 活接焊接等;

8.适用介质:天然气、人工煤气、液化石油气、空气等多种气体

9.适用压力:1.0~100.0MPa

10.适用温度:-196~600℃

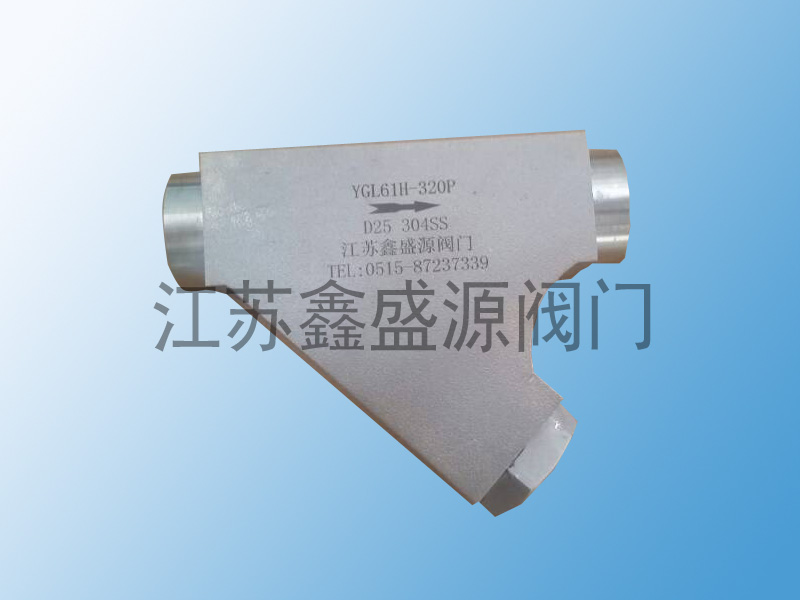

Y型加气站焊接过滤器

Y型加气站焊接过滤器是一种专门为天然气(CNG/LNG)、氢气(H₂)等气体加气站管道系统设计的特种过滤设备。其采用Y型结构和焊接连接方式,核心功能是有效滤除输送气体中的固体颗粒物、水分油雾等杂质,确保加气站核心设备(如压缩机、储气瓶组、加气机)的安全、稳定、有效运行。

2. Y型加气站焊接过滤器核心特点

高洁净度保障: 内置高精度滤芯(如烧结网、纤维毡),能有效过滤超细颗粒,提供极高洁净度的气体,满足燃料气体质量要求。

焊接连接,密封: 采用对焊(Butt Weld)或承插焊(Socket Weld)方式,实现与管道长久性连接,彻底杜绝外泄漏,安全等级。

结构紧凑,压降小: Y型结构设计流畅,流体阻力小,压力损失低,加气效率。

耐高压设计: 严格遵循高压管道设计规范(如ASME B31.3),阀体通常为锻件,能承受加气站系统的高工作压力(通常为25MPa以上乃至45MPa、100MPa)。

专用材料与表面处理: 与介质接触的部件通常采用奥氏体不锈钢(如304、316L),确保材料兼容性,防止腐蚀污染气体。内外表面进行抛光处理(如电解抛光),减少吸附、易于清洁。

维护便捷: 通常设计有可开启的滤罐(Pot),方便快速更换或清洗滤芯。

3. Y型加气站焊接过滤器工作原理

带杂质的气体从过滤器进口进入,流经Y型腔体内的过滤元件。杂质被滤材拦截并积聚在滤壳内,洁净的气体则从出口流出,进入下游的干燥器、压缩机或储气装置。当压差达到设定值(表明滤芯堵塞)时,需停机更换滤芯。

4. Y型加气站焊接过滤器关键应用点

安装在加气站工艺流程中的多个关键位置:

进站过滤: 在站入口总管上,过滤来自管网或运输槽车的原始气体。

压缩机前过滤: 保护压缩机缸体、活塞环、密封件免受颗粒磨损。

储气瓶组前/后过滤: 防止杂质进入储气设施或随气体进入加气机。

加气机前过滤(过滤): 作为后一道保障,确保加注到车辆的气体洁净,保护车辆燃料系统。

5. Y型加气站焊接过滤器行业标准

设计制造常遵循以下标准:

压力管道规范: ASME B31.3

阀门标准: ASME B16.34

焊接端标准: ASME B16.25

相关安全规范: NFPA 52(天然气车辆燃料系统规范)等。

Y-Type Welded Strainer for Fueling Station Product Overview

1. Product Definition

A Y-Type Welded Strainer for Fueling Stations is a specialized filtration device designed for the piping systems of natural gas (CNG/LNG) hydrogen (H₂) fueling stations. It features a Y-type configuration welded connections. Its core function is to efficiently remove solid particulates, moisture, oil mist, other contaminants the conveyed gas, ensuring the safe, stable, efficient operation of critical station equipment such as compressors, storage vessel banks, dispensers.

2. Key Features

High Cleanliness Assurance: Equipped with high-efficiency filter elements (e.g., sintered mesh, fiber felt) that remove fine particles, delivering high-purity gas that meets fuel quality specifications.

Welded Connection, Absolute Sealing: Utilizes butt weld socket weld connections to create a permanent, leak-tight joint with the pipeline, eliminating external leakage providing the highest level of safety.

Compact Design, Low Pressure Drop: The Y-type design offers a streamlined flow path with minimal fluid resistance low-pressure loss, ensuring fueling efficiency.

High-Pressure Resistance: Designed manufactured in strict compliance with high-pressure piping codes (e.g., ASME B31.3). The body is often a forging, capable of withstanding the high operating pressures common in fueling stations (typically 25MPa above, up to 45MPa 100MPa).

Dedicated Materials & Surface Treatment: Wetted parts are typically made of austenitic stainless steel (e.g., 304, 316L) to ensure material compatibility prevent corrosive contamination of the gas. Internal external surfaces receive high-level finishing (e.g., electropolishing) to reduce adsorption facilitate cleaning.

Easy Maintenance: Often designed with an openable filter pot for quick replacement cleaning of the filter element.

3. Working Principle

Contaminated gas enters the strainer through the inlet passes through the filter element housed in the Y-shaped chamber. Contaminants are trapped by the filter media accumulate in the housing, while clean gas exits through the outlet to downstream equipment (dryers, compressors, storage). The filter element requires replacement when the differential pressure across it reaches a set value (indicating clogging).

4. Critical Application Points

Installed at multiple key locations within the fueling station process:

Station Inlet Filtration: On the main incoming header to filter raw gas the pipeline transport trailers.

Pre-Compressor Filtration: Protects compressor cylinders, piston rings, seals particulate abrasion.

Pre/Post Storage Bank Filtration: Prevents contaminants entering storage vessels being carried over into the dispensers.

Pre-Dispenser Filtration (Final Filtration): Serves as the final barrier, ensuring the gas dispensed into vehicles is clean, protecting the vehicle's fuel system.

5. Industry Standards

Design manufacturing often adhere to the following standards:

Piping Code: ASME B31.3

Valve Standard: ASME B16.34

Welding End Standard: ASME B16.25

Safety Code: NFPA 52 (Vehicular Natural Gas Fuel Systems Code), etc.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!