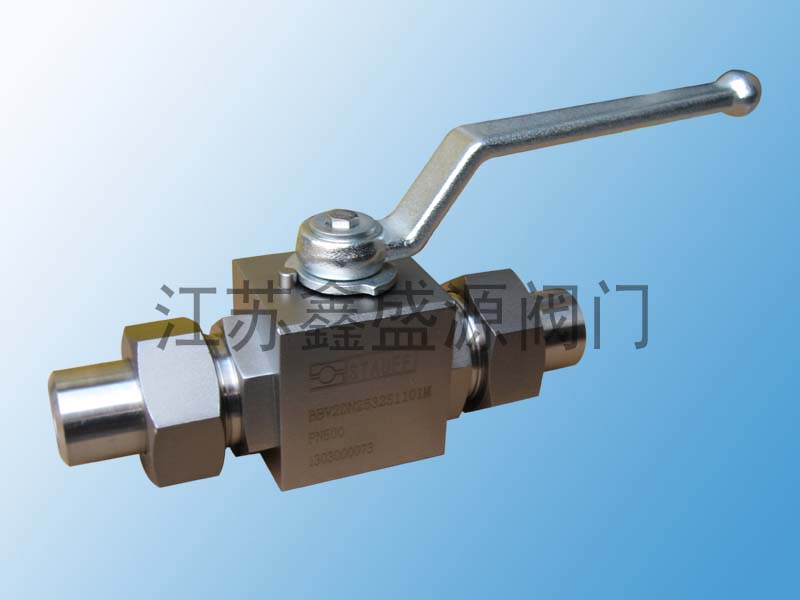

西德福(STAUFF)是德国的专业阀门设计和制造商,其高压球阀以其坚固的结构、密封性能和广泛的应用领域而闻名。焊接式高压球阀是西德福产品线中的重要一员,它通过焊接方式与管道系统连接,旨在提供一种长久性、无泄漏的解决方案,特别适用于高压、高要求或空间受限的工况。

焊接式西德福高压球阀这类阀门通常采用不锈钢阀体、不锈钢球体和阀杆,并配备特殊的阀座和密封材料,以适应高压和严苛介质。西德福公司已获得 ISO9001认证,其产品质量和性能有可信保障。

焊接式西德福高压球阀技术详情与应用

西德福焊接式高压球阀的主要技术参数和应用信息汇总如下:

焊接式西德福高压球阀项目 详细信息

代表性型号 BBVF 型 (带焊接端的高压圆形阀体球阀)

压力范围 高达 345 bar / 5000 PSI (取决于尺寸和材料组合),特殊定制压力可达 800 bar / 12000 PSI

温度范围 标准工作温度 -20°C 至 +100°C,特殊设计可达 +500°C / +930°F

阀体材质 不锈钢 (标准),碳钢 (镀锌处理)

球体与阀杆 不锈钢

阀座材料 Delrin (POM) 或其他特殊材料 (适用于低/高温或腐蚀性介质)

密封材料 FPM (Viton) O型圈

焊接式西德福高压球阀连接方式 焊接端 (如 DIN 法兰连接带焊接端)

驱动方式 手动 (配备可移动可调节手柄)

安全系数 工作压力安全系数 3:1

适用介质 液压油、水、气体 (包括天然气)、腐蚀性介质等

行业应用 工程机械、矿山机械、石油化工、能源技术、轨道交通、船舶海洋

焊接式西德福高压球阀产品特点:

· 焊接连接:提供牢固的管道连接,很大限度地减少泄漏风险。

· 高压耐受:专为高压工况设计,部分型号压力等级高达6000 PSI。

· 耐腐蚀性:不锈钢阀体及特殊表面处理(如碳钢阀体的锌镍镀层,盐雾试验超过720小时),提供良好的耐腐蚀性。

· 低操作扭矩:精加工的部件减小了操作扭矩,启闭方便。

· 密封稳定:浮动式球体设计确保密封无泄漏,并能自动补偿阀座磨损,泄漏等级符合EN12266 A级标准。

· 焊接式西德福高压球阀长使用寿命:阀座材料耐磨且具有自润滑功能,不锈钢抛光球体减少了摩擦和阀座磨损。

焊接式西德福高压球阀使用建议

· 焊接式西德福高压球阀型号确认:以上信息主要以BBVF等型号为例。西德福球阀系列繁多(例如BKH, MKH等),请根据具体应用需求确认合适的型号。

· 专业安装:焊接式球阀对安装工艺要求较高,建议由专业人员进行安装和焊接,以确保系统完整性。

· 焊接式西德福高压球阀使用注意:对于手动操作型号,在工作状态下手柄必须固定在中间位置,以防在震动中自行转动。

German STAUFF Welded High-Pressure Ball Valve Product Overview

Company Profile:

STAUFF is a German professional valve designer manufacturer.Its high-pressure ball valves are renowned for their robust construction, excellent sealing performance, wide range of applications. The welded high-pressure ball valve is an important part of STAUFF's product line. It connects to the pipeline system via welding, aiming to provide a permanent, leak-free solution, especially suitable for high-pressure, demanding, space-constrained working conditions.

These valves typically feature a stainless steel body, stainless steel ball stem, are equipped with special seat sealing materials to withstand high pressure harsh media. STAUFF has obtained ISO9001 certification, ensuring reliable quality performance of its products.

Technical Details Applications

Representative Models:

BBVF Type(High-Pressure Round Body Ball Valve with welding ends)

Key Technical Parameters:

· Pressure Rating: Up to 345 bar / 5000 PSI (depending on size material combination). Special customizations can achieve pressures up to 800 bar / 12000 PSI.

· Temperature Range: Standard operating temperature -20°C to +100°C. Special designs can reach +500°C / +930°F.

· Body Material: Stainless steel (standard), Carbon steel (zinc-nickel plated).

· Ball Stem: Stainless steel.

· Seat Material: Delrin (POM) other special materials (for low/high temperatures corrosive media).

· Sealing Material: FPM (Viton) O-rings.

· Connection Type: Welding ends (e.g., with DIN flange connections welding ends).

· Actuation Method: Manual (equipped with removable adjustable handle).

· Safety Factor: Working pressure safety factor 3:1.

· Suitable Media: Hydraulic oil, water, gases (including natural gas), corrosive media, etc..

· Industry Applications: Construction machinery, Mining machinery, Petrochemical, Energy technology, Rail transportation, Marine offshore.

Product Features:

· Welded Connection: Provides a secure pipeline connection, minimizing leakage risk.

· High-Pressure Resistance: Designed for high-pressure conditions, some models rated up to 6000 PSI.

· Corrosion Resistance: Stainless steel body special surface treatments (e.g., zinc-nickel plating for carbon steel bodies, salt spray test over 720 hours) offer good corrosion resistance.

· Low Operating Torque: Precision-machined components reduce operating torque, enabling easy operation.

· Reliable Sealing: Floating ball design ensures tight sealing without leakage can automatically compensate for seat wear. Leakage rate conforms to standard EN12266 A.

· Long Service Life: Wear-resistant self-lubricating seat material, polished stainless steel ball reduces friction seat wear.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!