CNG高压过滤器是输送介质的管道系统不可缺少的一种过滤装置,CNG高压过滤器通常安装在减压阀、泄压阀、定水位阀或其它设备的进口端,用来清除介质中的杂质,以保护阀门及设备的正常使用。

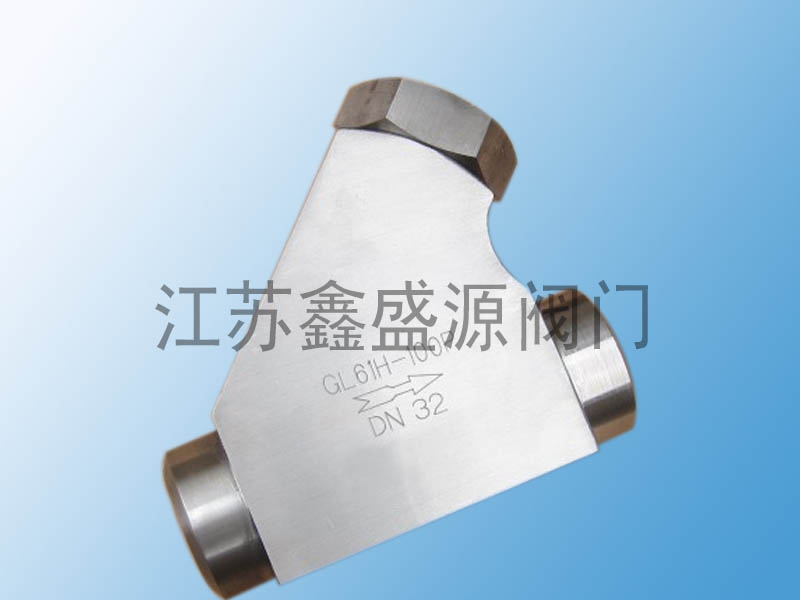

CNG高压过滤器具有结构,阻力小,排污方便等特点。CNG高压过滤器适用介质可为水、油、气。一般通水网为18~30目,通气网为10~100目,通油网为100~480目。

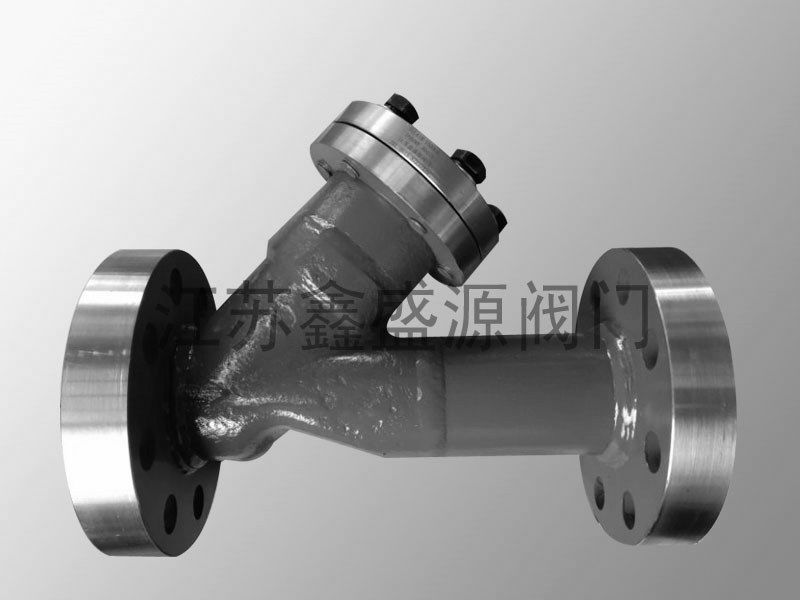

篮式过滤器主要由接管、主管、滤蓝、法兰、法兰盖及紧固件等组成。当液体通过主管进入滤蓝后,固体杂质颗粒被阻挡在滤蓝内,而洁净的流体通过滤蓝、由过滤器出口排出。

CNG高压过滤器广泛用于CNG设备入口段过滤,后端设备使用寿命,适用液化气、天然气、空气等介质。

产品特点:

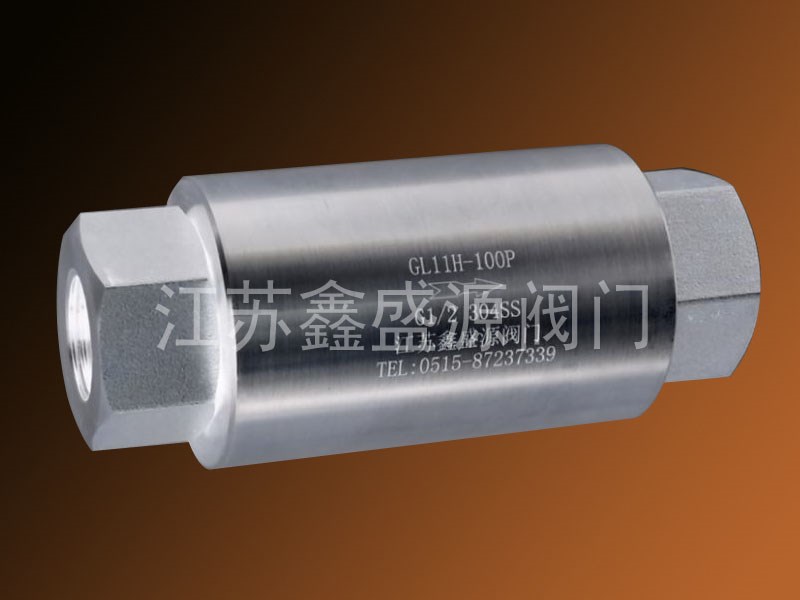

1.CNG高压过滤器适用于压缩天然气系统高压过滤单元;

2.过滤高、流通能力大、结构紧凑;

3.流通能力大,始于200-2500方CNG减压撬;

4.结构简单,可在线维修;

5.流通能力大,结构紧凑;密封严密,无气体渗漏;

6.安装省力,经济实惠;

7.连接方式:螺纹连接;

8.可用于天然气、人工煤气、液化石油气、空气等多种气体。

CNG高压过滤器

CNG高压过滤器是压缩天然气(CNG)输送系统、加气站及终端应用中的关键净化设备。其核心功能是滤除天然气中的固体颗粒物、液滴、油分等杂质,确保下游设备(如储气井、顺序控制盘、加气机、车辆气瓶等)免受污染和磨损,保障整个CNG系统的安全、稳定、运行。

CNG高压过滤器核心特点与功能:

CNG高压过滤器高压耐受性:专为CNG系统的高压环境设计(通常工作压力为20-25MPa,可达30MPa或更高),采用高强度材料(如碳钢、不锈钢)和符合压力容器标准的制造工艺。

过滤:内置单级或多级高精度滤芯(如不锈钢金属烧结网、玻璃纤维等),能有效拦截微米级(如1μm, 3μm, 10μm)的颗粒物和气溶胶。

CNG高压过滤器聚结分离:许多过滤器兼具聚结功能,能 coalesce 微小的液滴和油雾,使其聚集成大液滴,并通过排污口排出,实现气液分离。

CNG高压过滤器大流量设计:优化设计的内部流道和过滤面积,确保在高压下具有高流通能力,压力损失小,减少对加气效率的影响。

CNG高压过滤器结构坚固安全:阀体通常为无缝钢管或锻件制造,符合ASME、GB等国家压力容器标准,配备安全阀和排污阀。

CNG高压过滤器维护简便:滤芯采用可更换式设计,压差计或视觉指示器可显示滤芯堵塞情况,提醒及时更换。

CNG高压过滤器典型应用:

CNG加气站(母站、子站、标准站)的进气预处理和出口净化

CNG长管拖车或管束式集装箱的输气系统

CNG储气设施(群)的配套净化

CNG车辆燃料系统的进气过滤

天然气液压减压站(CNG减压站)的前置保护

Product Overview of High-Pressure CNG Filters

A high-pressure CNG (Compressed Natural Gas) filter is a critical purification unit within CNG transmission systems, refueling stations, end-use applications. Its core function is to efficiently remove solid particulates, liquid droplets, oil contaminants, other impurities the natural gas stream. This protects downstream equipment (such as storage vessels, priority panels, dispensers, vehicle fuel cylinders) contamination abrasion, ensuring the safe, stable, efficient operation of the entire CNG system.

Key Features Functions:

High-Pressure Resistance: Specifically designed for the high-pressure environment of CNG systems (typical operating pressures of 20-25 MPa, up to 30 MPa higher). Constructed with high-strength materials (e.g., carbon steel, stainless steel) manufactured according to pressure vessel standards.

High-Efficiency Filtration: Equipped with single multi-stage high-precision filter elements (e.g., sintered stainless steel mesh, glass fiber) capable of trapping micron-sized (e.g., 1μm, 3μm, 10μm) particulates aerosols.

Coalescing Separation: Many filters incorporate a coalescing function, which merges fine liquid droplets oil mist into larger droplets. These are then separated the gas stream discharged through a drain port, achieving effective gas-liquid separation.

High-Flow Capacity: Features an optimized internal flow path filtration area to ensure high flow capacity under pressure with minimal pressure drop, thus minimizing impact on refueling speed.

Robust Safe Construction: The vessel is typically manufactured seamless steel pipe forgings, complying with international national pressure vessel codes such as ASME GB. Equipped with safety valves drain valves.

Easy Maintenance: Designed with replaceable filter elements. A differential pressure gauge visual indicator signals when the element is clogged requires replacement.

Typical Applications:

CNG refueling stations (mother, daughter, standard stations) for inlet pre-filtration outlet purification.

Gas transmission systems for CNG tube trailers skids.

Associated purification for CNG storage facilities (banks).

Inlet filtration for CNG vehicle fuel systems.

Pre-filtration protection in CNG pressure reduction stations.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!