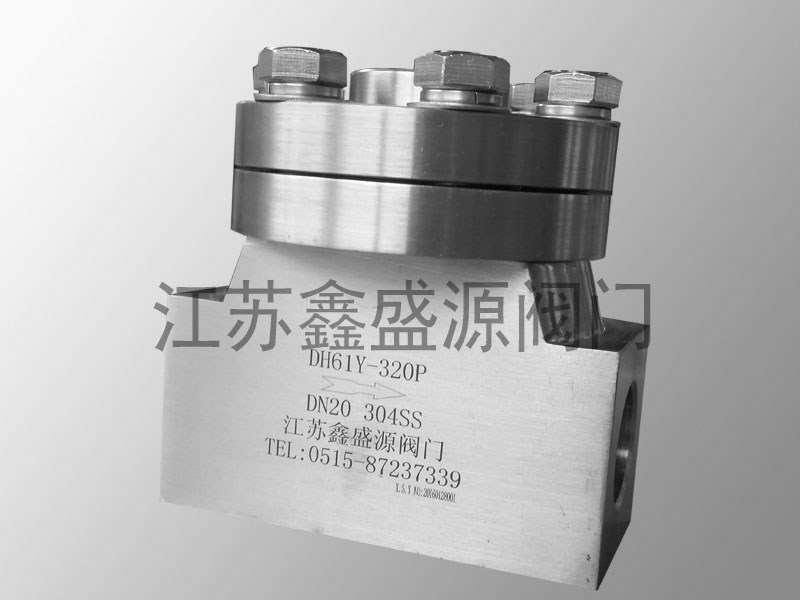

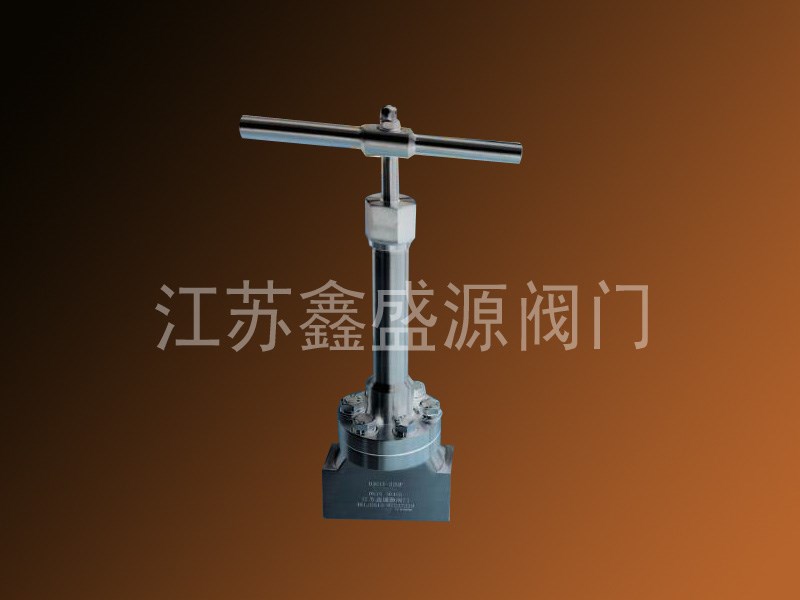

DQ21低温高压焊接球阀用于超低温高压的工矿下,可以在-196℃,42MPa的情况下正常工作。特殊的低温环境下设计了加长阀杆,有效的保护操控的安全。主要适合LNG 液氧 液氮 乙二胺等低温和超低温管线着起闭用。DQ21低温高压焊接球阀它具有旋转90度的动作,旋塞体为球体,有圆形通孔或通道通过其轴线。球阀在管路中主要用来做切断、分配和改变介质的流动方向,它只需要用旋转90度的操作和很小的转动力矩就能关闭严密。球阀适宜做开关、切断阀使用。

DQ21低温高压焊接球阀优点:

1.流体阻力小,全通径的球阀基本没有流阻。

2.结构简单、体积小、重量轻、耐高压。

3.紧密稳定。它有两个密封面,而且目前球阀的密封面材料广泛使用各种塑料,密封性好,能实现完全密封。在真空系统中也已广泛使用。

4.操作方便,开闭迅速,从全开到全关只要旋转90°,便于远距离的控制。

5.维修方便,球阀结构简单,密封圈一般都是活动的,拆卸更换都比较方便。

6.在全开或全闭时,球体和阀座的密封面与介质隔离,介质通过时,不会引起阀门密封面的侵蚀。

7.适用范围广,通径从小到几毫米,大到几米,从高真空至高压力都可应用。

8.由于球阀在启闭过程中有擦拭性,所以可用于带悬浮固体颗粒的介质中。

低温高压焊接球阀产品概述

低温高压焊接球阀是一种适用于低温且高压工况的阀门,专为在极端环境下控制流体介质而设计。以下是其产品概述:

低温高压焊接球阀 - 工况适应性:能在极低温度(如-196℃及以下)和高压(通常可达Class 900及以上压力等级)环境中稳定工作,可耐受液氮、液化天然气(LNG)等低温介质的冲击。

低温高压焊接球阀 - 结构特点:采用焊接连接方式,阀体与管道焊接为一体,密封性能强,能有效防止低温介质泄漏。阀芯多为浮动式或固定式设计,阀杆配备低温专用填料,避免因温度变化导致的密封失效。部分型号设有防结霜结构,减少低温对操作部件的影响。

低温高压焊接球阀 - 材质选择:阀体常用低温钢(如304L、316L不锈钢)或镍基合金,耐低温冲击性好;密封材料选用耐低温的增强聚四氟乙烯(PTFE)或金属密封,确保在低温下不脆化、不泄漏。

低温高压焊接球阀 - 性能优势:具备耐低温高压性能,开关灵活,操作扭矩稳定。焊接结构抗振动、抗冲击性强,适用于移动设备或管道振动频繁的场景。维护周期长,可减少极端环境下的检修次数。

低温高压焊接球阀 - 应用领域:广泛用于LNG储存与运输、低温化工、航空航天燃料系统、超导实验装置等领域,是低温高压流体控制系统的关键部件。

Product Overview of Cryogenic High-pressure Welded Ball Valve

The cryogenic high-pressure welded ball valve is a type of valve designed for low-temperature high-pressure working conditions, specifically engineered to control fluid media in extreme environments. The product overview is as follows:

Product Overview of Cryogenic High-pressure Welded Ball Valve- Working Condition Adaptability: It can work stably in extremely low temperatures (e.g., -196℃ below) high pressures (usually up to Class 900 higher pressure classes), can withstand the impact of cryogenic media such as liquid nitrogen liquefied natural gas (LNG).

Product Overview of Cryogenic High-pressure Welded Ball Valve- Structural Features: It adopts a welded connection method, with the valve body welded integrally with the pipeline, ensuring strong sealing performance effectively preventing leakage of cryogenic media. The valve core is mostly of floating fixed design, the valve stem is equipped with cryogenic-specific packing to avoid seal failure caused by temperature changes. Some models are equipped with anti-frosting structures to reduce the impact of low temperatures on operating components.

Product Overview of Cryogenic High-pressure Welded Ball Valve- Material Selection: The valve body is commonly made of cryogenic steel (such as 304L, 316L stainless steel) nickel-based alloys, which have good low-temperature impact resistance; the sealing material is low-temperature-resistant enhanced polytetrafluoroethylene (PTFE) metal seals, ensuring no embrittlement leakage at low temperatures.

Product Overview of Cryogenic High-pressure Welded Ball Valve- Performance Advantages: It has excellent resistance to low-temperature high-pressure, with flexible opening closing stable operating torque. The welded structure has strong anti-vibration impact resistance, suitable for mobile equipment scenarios with frequent pipeline vibrations. The maintenance cycle is long, reducing the number of overhauls in extreme environments.

Product Overview of Cryogenic High-pressure Welded Ball Valve- Application Fields: Widely used in LNG storage transportation, cryogenic chemical industry, aerospace fuel systems, superconducting experimental devices other fields, it is a key component of cryogenic high-pressure fluid control systems.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!