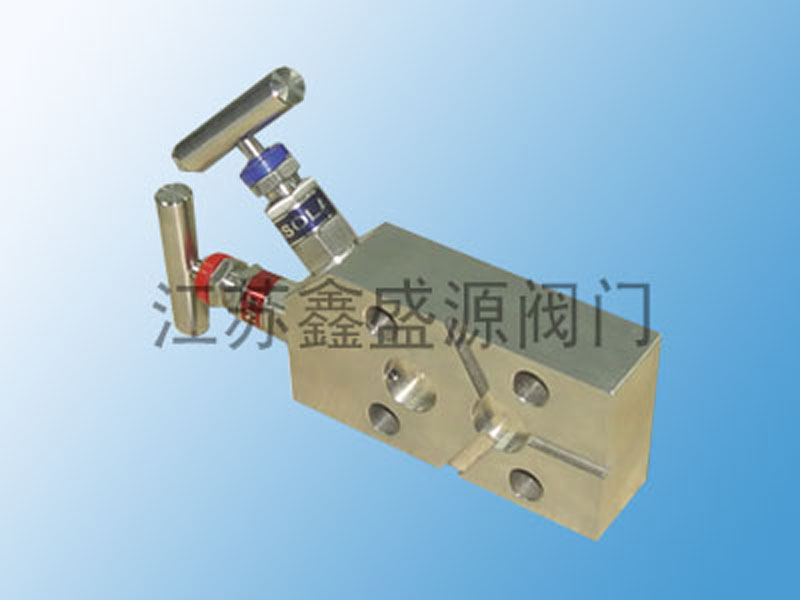

产品名称:共面型二阀组

产品型号:DRCC2

所属类别:仪表阀组 >> 两阀组

所属系列:DR

共面型二阀组安装尺寸图

| 订货信息 | ||||

| 代码 | 结构件材料 | |||

| 阀体 | 阀帽 | 阀杆 | 泄放/排污堵头 | |

| 1 | 304SST | 304SST | 304SST | 304SST |

| 2 | 316SST | 316SST | 316SST | 316SST |

| 代码 | 填料 | |||

| 1 | 四氟乙烯 | |||

| 2 | 石墨 | |||

| 代码 | DR阀组选项 | |||

| 共面型阀组支架 | ||||

| B4 | 用于2-in.管安装的不锈钢支架 300 不锈钢螺栓 | |||

| 清洗 | ||||

| P2 | 特殊清洗(禁油),仅适用填料为四氟乙烯的场合 | |||

| 接头(用于阀组类型代码C) | ||||

| CA | 1/2-14NPTM-Ф14×2对焊接头 | |||

| CB | 1/2-14NPTM-Ф1/2-in卡套接头 | |||

| CC | 1/2-14NPTM-Ф12卡套接头 | |||

| CD | 1/2-14NPTM-Ф6卡套接头 | |||

| CS | 定制接头 | |||

| 接头(用于阀组类型代码T) | ||||

| TA | 1/4-18NPTM-Ф14×2 对焊接头 | |||

| TB | 1/4-18NPTM-Ф1/2-in 卡套接头 | |||

| TC | 1/4-18NPTM-Ф12 卡套接头 | |||

| TD | 1/4-18NPTM-Ф6 卡套接头 | |||

| TS | 定制接头 | |||

| 转换法兰(用于阀组类型代码T) | ||||

| DF | 1/2-14 NPTF 转换法兰 | |||

| DS | 定制法兰 | |||

| 过程法兰连接孔规格(用于阀组类型代码T) | ||||

| HK | M10×1.5 内螺纹 | |||

| 组装 | ||||

| IA | 与仪表一体化组装并打压测试 | |||

共面型二阀组

共面型二阀组是一种高性能、高密封性的集成阀组,专为差压变送器(DP Transmitter)设计。其核心特点是两个截止阀的阀杆通道(阀座)位于同一个平面上,并通过一个共同的阀盖(Bonnet) 实现密封。这种设计确保了阀门在开关过程中,与变送器测量膜片直接接触的介质容积变化极小,从而极大限度地减小对测量精度的影响。

共面型二阀组主要功能与用途

该阀组是差压流量、液位测量系统中的关键组成部分,主要用于:

过程隔离:同时隔离差压变送器的高压(HP)和低压(LP)侧与过程管道。

仪表投用/停用:通过特定的操作顺序,安全地将变送器投入运行或从流程中切出。

零点校验与迁移:在投用前或维护时,通过平衡阀(通常为三阀组的一部分,但共面二阀组常与集成平衡阀的变送器配套)对变送器进行零点校验。

在线维护:允许在不停车的情况下,对差压变送器进行故障处理、更换或校准。

共面型二阀组主要特点

共面密封(Coplanar Sealing):这是其很明显的特点。两个阀门的阀杆通道在同一平面,共享一个阀盖和密封系统,结构极其紧凑,密封稳定性极高,极大降低了潜在泄漏点。

高精度测量:阀芯的特殊设计使其在开关过程中引起的“容积变化”极小,有效防止对差压变送器敏感膜片造成压力冲击,确保了测量系统的准确度和稳定性。

安全性高:整体锻造或棒材加工的阀体强度高,能承受更高压力;共面设计减少了连接点,降低了泄漏风险。

操作符合规程:阀组操作顺序(如:开阀时先开高压阀,再开低压阀;关阀时先关低压阀,再关高压阀)被集成到设计中,有助于规范操作,防止误操作导致仪表损坏。

材料与工艺:阀体通常采用316不锈钢、合金钢等材料;阀芯和阀座常进行硬化处理,密封件采用石墨、PTFE等,适用于高温、高压、腐蚀性等苛刻工况。

共面型二阀组与其它阀组(丁式、内外螺纹式)的区别

丁式二阀组:结构更简单,常用于单一压力测量,功能偏向隔离和泄压。

内外螺纹式二阀组:强调连接端的灵活性,功能通用,可用于压力或差压场合,但非共面设计。

共面型二阀组:是专为差压测量设计的产品,其共面设计、低容积变化和高密封性是其独特优势,通常用于对测量精度和安全性要求极高的场合。

共面型二阀组典型应用行业

石油与天然气(特别是上游开采和炼化)、化工、制药、核电等对过程控制精度和安全要求极高的行业。

Coplanar Two-Valve Manifold Product Overview

Product Definition

A coplanar two-valve manifold is a high-performance, high-integrity integrated valve manifold specifically designed for differential pressure (DP) transmitters. Its defining feature is that the valve stem passages (seats) for the two shut-off valves lie on the exact same plane are sealed by a common bonnet. This design ensures minimal change in the fluid volume contacting the transmitter's diaphragm during valve operation, thereby minimizing impact on measurement accuracy.

Primary Function & Application

This manifold is a critical component in differential pressure flow level measurement systems. Its primary uses include:

Process Isolation: To simultaneously isolate both the high-pressure (HP) low-pressure (LP) sides of the differential pressure transmitter the process piping.

Instrument Commissioning/Decommissioning: To safely put the transmitter into service take it out of service following a specific operating sequence.

Zero Checking & Span Adjustment: To check the transmitter's zero point before commissioning during maintenance (often facilitated by an integral equalizing valve on the transmitter itself when used with a two-valve manifold).

In-line Maintenance: To allow for troubleshooting, replacement, calibration of the DP transmitter without requiring a process shutdown.

Key Features

Coplanar Sealing: This is its most distinctive feature. The two valve seats are on a single plane with a shared bonnet sealing system. This results in an extremely compact design, exceptionally high sealing reliability, a significant reduction in potential leak paths.

High Measurement Accuracy: The specialized valve plug design creates minimal "volume shift" during operation, effectively preventing pressure shocks to the sensitive diaphragm of the DP transmitter ensuring measurement precision stability.

High Safety: The valve body, often forged machined bar stock, offers high strength can withstand higher pressures. The coplanar design reduces the number of connections, lowering the risk of leakage.

Procedural Operation: The design incorporates encourages the correct operating sequence (e.g., open the HP valve before the LP valve when commissioning; close the LP valve before the HP valve when isolating), helping to prevent misuse instrument damage.

Materials & Construction: Valve bodies are typically made high-quality materials like 316 stainless steel alloy steel. Valve plugs seats are often hardened, seals made materials like graphite PTFE make it suitable for harsh conditions including high temperature, high pressure, corrosive media.

Difference Other Manifolds (T-Pattern, Internal/External Thread)

T-Pattern Two-Valve Manifold: Simpler in structure, commonly used for single-pressure measurement, focusing on isolation venting.

Internal & External Thread Two-Valve Manifold: Emphasizes connection flexibility; it's a general-purpose manifold for pressure differential applications but lacks the coplanar design.

Coplanar Two-Valve Manifold: This is a premium product specifically engineered for differential pressure measurement. Its coplanar design, low volumetric change, high sealing integrity are unique advantages, typically reserved for applications demanding the highest measurement accuracy safety.

Typical Application Industries

Oil & Gas (particularly upstream production refining), Chemical Processing, Pharmaceuticals, Nuclear Power, other industries with extremely high demands for process control accuracy safety.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!