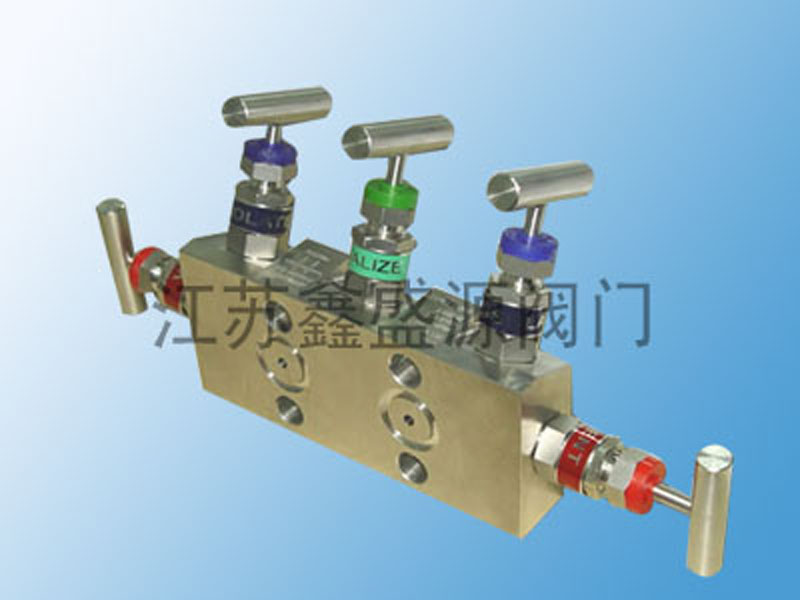

产品名称:W式五阀组

产品型号:DCCW5

所属类别:仪表阀组 >> 五阀组

所属系列:DC

安装尺寸图

| 订货信息 | ||||

| 代码 | 结构件材料 | |||

| 阀体 | 阀帽 | 阀杆 | 泄放/排污堵头 | |

| 1 | 304SST | 304SST | 304SST | 304SST |

| 2 | 316SST | 316SST | 316SST | 316SST |

| 代码 | 填料 | |||

| 1 | 四氟乙烯 | |||

| 2 | 石墨 | |||

| 代码 | 安装螺栓 | |||

| BA | 与传统型压力变送器直接安装 螺栓孔规格7/16UNF | |||

| BB | 与传统型压力变送器直接安装 螺栓孔规格M10×1.5 | |||

| BC | 与共面法兰型3051C 变送器直接安装 | |||

| BD | 与传统法兰型3051C 变送器直接安装 | |||

| BS | 定制螺栓 | |||

| 代码 | DC阀组选项 | |||

| 安装支架 | ||||

| B4 | 用于2-in.管安装的不锈钢支架 300 不锈钢螺栓,仅适用于阀组类型代码W | |||

| 排污泄放孔及堵头 | ||||

| PG | 带排污孔及堵头,仅适用于T型及H型三阀组 | |||

| 清洗 | ||||

| P2 | 特殊清洗(禁油),仅适用填料为四氟乙烯的场合 | |||

| 接头(用于阀组类型代码W和T) | ||||

| CA | 1/2-14NPTM-Ф14×2对焊接头 | |||

| CB | 1/2-14NPTM-Ф1/2-in卡套接头 | |||

| CC | 1/2-14NPTM-Ф12卡套接头 | |||

| CD | 1/2-14NPTM-Ф6卡套接头 | |||

| CS | 定制接头 | |||

| 转换法兰(用于阀组类型代码H) | ||||

| DF | 1/2-14NPTF 转换法兰 | |||

| DS | 定制法兰 | |||

| 组装 | ||||

| IA | 与仪表一体化组装并打压测试 | |||

W式五阀组

W式五阀组是一种集成度更高、功能更全面的过程仪表阀组,其名称源于阀体内部流道与外部连接端口整体布局呈“W”形或“双W”形态。它是三阀组功能的扩展,专为要求更高安全性、更多在线维护功能的关键测量点而设计,尤其是在高压、危险介质(如天然气、氢气、有毒化学品)或贸易计量场合。

W式五阀组将五个阀门(两个过程隔离阀、一个平衡阀、两个排污/校验阀)精密地集成在一个坚固的阀体内,为差压变送器提供全面的保护、隔离、在线校验和排污吹扫功能。

W式五阀组主要特点与功能:

双重密封与安全保障: 专为苛刻工况设计。通常采用双阀座密封(Double Block & Bleed)理念,通过两个隔离阀和一个排污阀的组合,可在两个隔离阀之间形成一道可见的泄放腔,彻底隔离工艺介质并验证密封性,实现零泄漏隔离,安全等级好。

在线校验与排污: 两个独立的排污/校验阀(通常位于阀组底部)功能强大:

W式五阀组在线校验: 可在不停车的情况下,连接校验设备,对压力或差压变送器进行在线精度校验。

排污吹扫: 可分别对正、负压引压管进行排污,清除积液、杂质或冷凝物,确保引压管畅通,保障长期测量精度。

泄压功能: 在隔离仪表前,可通过此阀安全地释放引压管内的压力。

核心平衡功能: 平衡阀用于在投运或停运差压变送器时,平衡其膜片两侧的压力,防止单向过压损坏,这是保护精密变送器的核心功能。

一体化紧凑设计: 将多个功能集成于一体,减少了大量的法兰、接头和泄漏点,结构紧凑,安装方便,稳定性远高于分散的单个阀门组合。

W式五阀组高标准应用: 主要应用于石油天然气贸易计量(Fiscal Metering)、化工过程关键控制点、高压系统、以及任何需要高安全性和在线维护能力的场合。

功能阀门说明 (Function of Valves):

一个典型的W式五阀组通常包括:

高压侧隔离阀 (High-Pressure Block Valve)

低压侧隔离阀 (Low-Pressure Block Valve)

平衡阀 (Equalizing Valve)

高压侧排污/校验阀 (High-Pressure Vent/Drain Valve)

低压侧排污/校验阀 (Low-Pressure Vent/Drain Valve)

Product Overview of a W-Pattern 5-Valve Manifold

A W-Pattern 5-Valve Manifold is a more highly integrated functionally comprehensive process instrument valve assembly. Its name derives the "W" "double-W" shape formed by the internal flow channels external connection ports. It is an evolution of the 3-valve manifold, specifically designed for critical measurement points that demand higher safety greater online maintenance capabilities, especially in high-pressure services, with hazardous media (e.g., natural gas, hydrogen, toxic chemicals), for fiscal metering applications.

This manifold integrates five valves (two process block valves, one equalizing valve, two vent/drain/calibration valves) precisely into a robust body, providing comprehensive protection, isolation, online calibration, purging/blowdown functions for differential pressure (DP) transmitters.

Key Features Functions:

Double Seal Safety Assurance: Engineered for severe service. It often incorporates a Double Block Bleed (DBB) philosophy. The combination of two block valves one bleed valve creates a visible bleed cavity between them, allowing for complete isolation of the process medium verification of seal integrity. This achieves zero leakage isolation the highest safety standard.

Online Calibration Blowdown: The two independent vent/drain valves (typically located at the bottom) are highly functional:

Online Calibration: Allows connection to calibration equipment to perform online accuracy checks on pressure DP transmitters without shutting down the process.

Purging/Blowdown: Enables independent purging draining of the high low-pressure impulse lines to remove accumulated liquid, contaminants, condensate, ensuring clear impulse lines maintaining long-term measurement accuracy.

Pressure Relief: Allows for the safe venting of pressure the impulse lines before isolating the instrument.

Core Equalizing Function: The equalizing valve is used to balance pressure on both sides of the transmitter's diaphragm during start-up shutdown, preventing damage over-pressure on one side. This is the core function for protecting the sensitive transmitter.

Integrated Compact Design: Integrating multiple functions into a single unit significantly reduces the number of flanges, fittings, potential leak points. Its compact structure simplifies installation offers far greater reliability than a configuration of individual valves.

High-Standard Application: Primarily used in oil gas fiscal metering stations, critical chemical process control points, high-pressure systems, any application requiring high safety integrity online maintenance capabilities.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!