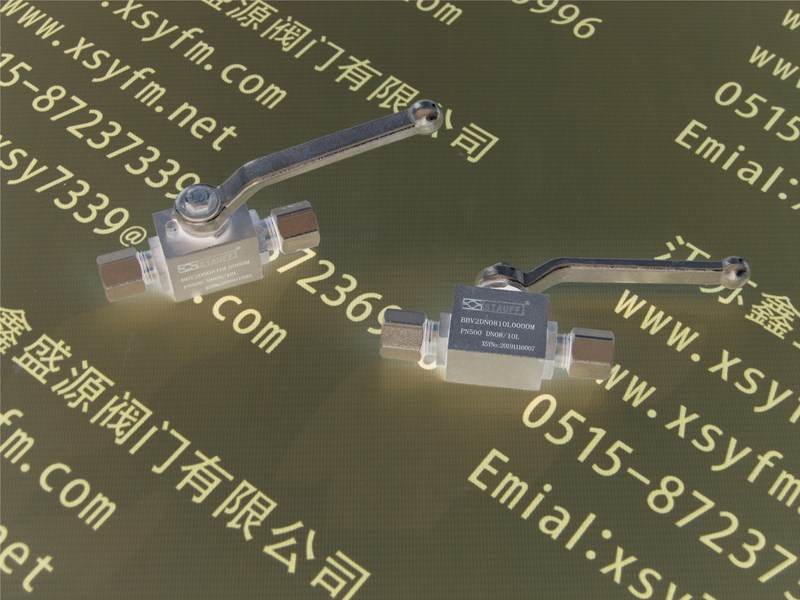

BBV2卡套高压球阀它具有旋转90度的动作,旋塞体为球体,有圆形通孔或通道通过其轴线。球阀在管路中主要用来做切断、分配和改变介质的流动方向,它只需要用旋转90度的操作和很小的转动力矩就能关闭严密。球阀适宜做开关、切断阀使用,但近来的发展已将球阀设计成使它具有节流和控制流量之用,如V型球阀。

BBV2卡套高压球阀采用卡套连接具有结构紧凑,密封度好,手感轻便,维修方便,密封面与球面常在闭合状态,不易被介质冲蚀,易于操作和维修,适用于水、溶剂、酸和天然气等一般工作介质,而且还适用于工作条件恶劣的介质,如氧气、过氧化氢、甲烷和乙烯等,在各行业得到广泛的应用。球阀阀体可以是整体的,也可以是组合式的。

BBV2卡套高压球阀优点:

1.流体阻力小,全通径的球阀基本没有流阻。

2.结构简单、体积小、重量轻。

3.紧密度好。它有两个密封面,而且目前球阀的密封面材料广泛使用各种塑料,密封性好,能实现完全密封。在真空系统中也已广泛使用。

4.操作方便,开闭迅速,从全开到全关只要旋转90°,便于远距离的控制。

5.维修方便,球阀结构简单,密封圈一般都是活动的,拆卸更换都比较方便。

6.在全开或全闭时,球体和阀座的密封面与介质隔离,介质通过时,不会引起阀门密封面的侵蚀。

7.适用范围广,通径从小到几毫米,大到几米,从高真空至高压力都可应用。

8.由于球阀在启闭过程中有擦拭性,所以可用于带悬浮固体颗粒的介质中。

碳钢卡套高压球阀

碳钢卡套高压球阀是一种结合碳钢阀体与卡套连接结构的高压控制阀门,专为高压工况设计,适用于需要稳定密封和高强度承压的管路系统。其核心特点在于:阀体采用好的碳钢(如A105)制造,具备很好的力学性能和耐压能力,可适应高压介质输送;连接方式采用卡套结构,通过卡套与管道外壁的机械咬合实现密封,无需焊接或螺纹紧固,安装便捷且密封度好,能有效抵抗振动和压力波动。

碳钢卡套高压球阀由球体、阀座、碳钢阀体、卡套组件(卡套、螺母)、阀杆及操作机构等构成,工作原理基于球体旋转90°实现介质通断:球体通道与管路对齐时全开,旋转至垂直状态时,球体与阀座紧密贴合截断介质。阀座多采用耐高压、耐磨损的材料(如金属或增强聚四氟乙烯),适配油、气、水等非腐蚀性介质。

碳钢卡套高压球阀其主要优势包括:1. 高压耐受能力强,公称压力通常可达31.5MPa及以上,满足高压系统需求;2. 碳钢材质成本适中,强度高,适合一般工业环境;3. 卡套连接安装速度好,后期维护拆装方便,密封性能稳定;4. 流通阻力小,介质输送效率高。

碳钢卡套高压球阀适用领域涵盖石油化工、液压系统、工程机械、能源传输等行业,尤其适用于高压、非腐蚀性介质且需要快速安装维护的管路控制场景。

Product Overview of Carbon Steel Ferrule High-Pressure Ball Valve The carbon steel ferrule high-pressure ball valve is a high-pressure control valve combining a carbon steel valve body with a ferrule connection structure, designed specifically for high-pressure working conditions. It is suitable for pipeline systems requiring reliable sealing high-strength pressure resistance. Its core features are: the valve body is made of high-quality carbon steel (e.g., A105), which has excellent mechanical properties pressure resistance, enabling it to adapt to high-pressure medium transmission; the connection adopts a ferrule structure, achieving sealing through mechanical engagement between the ferrule the outer wall of the pipeline. No welding thread fastening is needed, ensuring convenient installation reliable sealing, with strong resistance to vibration pressure fluctuations.

The valve consists of components such as a ball, valve seat, carbon steel valve body, ferrule assembly (ferrule, nut), valve stem, operating mechanism. Its working principle is based on the 90° rotation of the ball to control the medium's on-off: when the ball's channel is aligned with the pipeline, the valve is fully open; when rotated to a vertical state, the ball fits tightly with the valve seat to shut off the medium. The valve seat is mostly made of high-pressure wear-resistant materials (such as metal reinforced polytetrafluoroethylene), suitable for non-corrosive media like oil, gas, water.

Its main advantages include: 1. Strong high-pressure resistance, with a nominal pressure usually reaching 31.5MPa higher, meeting the needs of high-pressure systems; 2. Moderate cost of carbon steel material, high strength, suitable for general industrial environments; 3. Efficient installation with ferrule connection, convenient disassembly maintenance in later stages, stable sealing performance; 4. Low flow resistance, ensuring high efficiency in medium transmission.

It is widely used in industries such as petrochemicals, hydraulic systems, engineering machinery, energy transmission, especially suitable for pipeline control scenarios involving high-pressure, non-corrosive media that require quick installation maintenance.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!