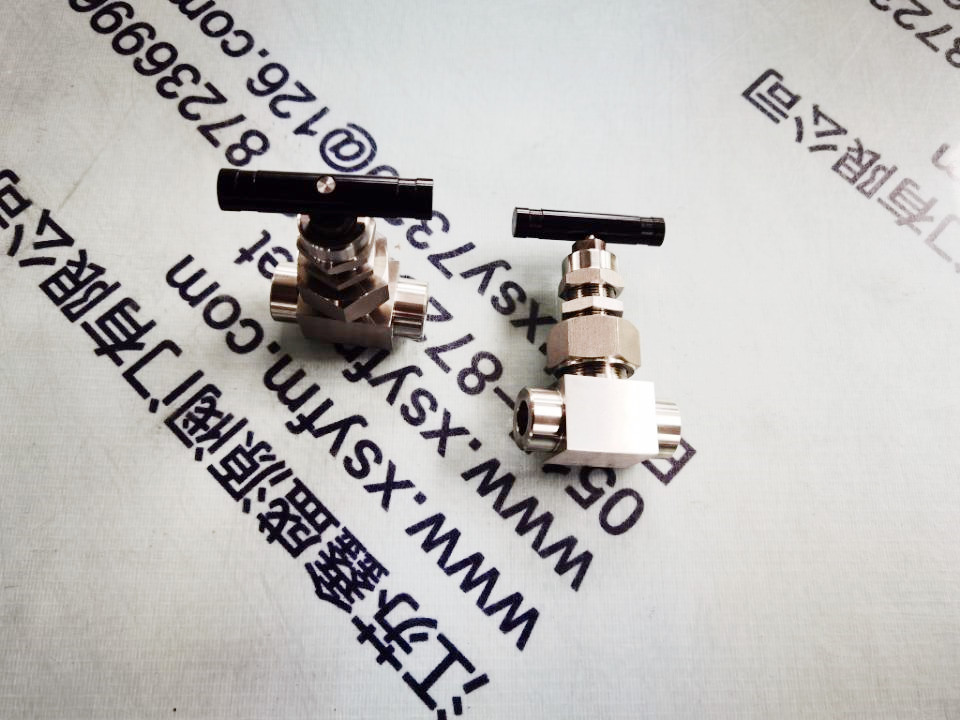

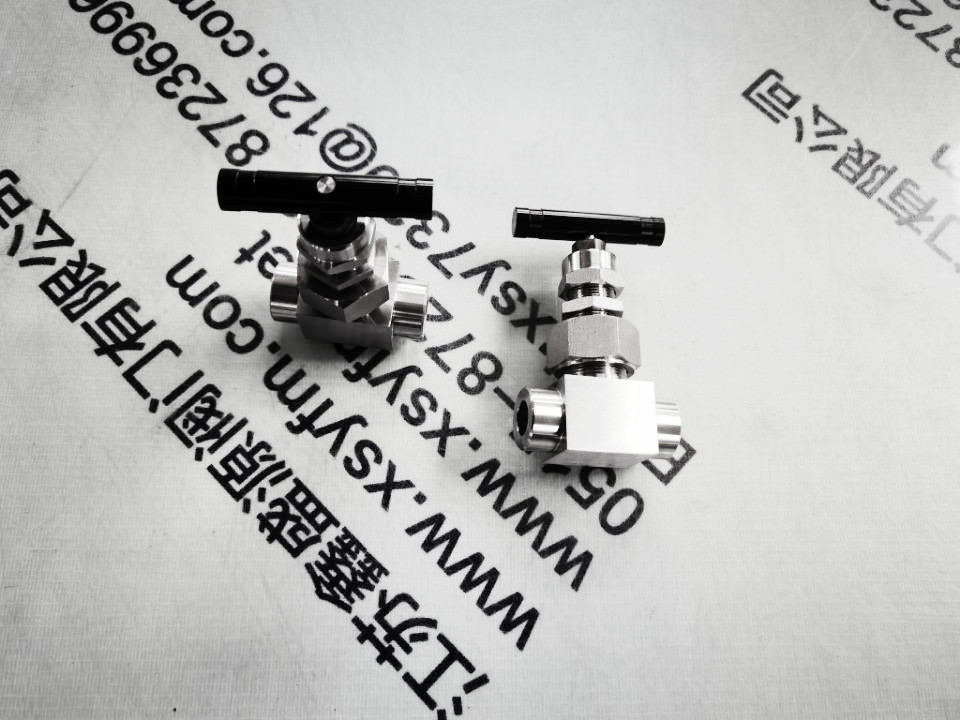

高温高压截止阀结构设计:

阀体结构:通常采用锻造工艺制造,具有高强度和良好的密封性。阀体形状根据不同的类型有所差异,常见的有直通式、直角式及直流式斜截止阀。内腔设计光滑,以减少流体阻力。

阀瓣与阀座:阀瓣是截止阀的启闭件,密封面呈平面或锥面,与阀座紧密配合实现密封。阀瓣沿流体的中心线作直线运动,阀座固定在阀体上,其密封面通常采用硬质合金堆焊而成,如司太立(stellite)钴基硬质合金,具有耐磨、耐高温、抗擦伤性能好、使用寿命长等特点。

阀杆与手轮:阀杆的运动形式有升降杆式和升降旋转杆式两种。阀杆经调质和表面氮化处理,有良好的耐腐蚀性和抗擦伤性,连接阀瓣和手轮,通过手轮的旋转带动阀杆上下移动,从而控制阀瓣的启闭。

密封结构:采用压力自紧式密封结构,随着介质压力的增加,密封性能更好。此外,阀盖填料函深度合理,填料加缓蚀剂,进一步确保密封安全,防止介质泄漏。

高温高压截止阀工作原理:

依靠阀杆压力,使阀瓣密封面与阀座密封面紧密贴合,阻止介质流通,从而实现截止功能。当介质由阀瓣下方进入阀腔时,操作力需克服阀杆和填料的摩擦力与介质压力产生的推力,关阀力比开阀力大;而自密封阀门出现后,介质流向改由阀瓣上方进入阀腔,此时关阀力小,开阀力大,阀杆直径可相应减小,且这种形式的阀门密封性更好。

高温高压截止阀材料选择:

阀体材料:根据不同的使用工况和介质要求,可选用碳钢、合金钢、不锈钢等材料,如 ZG20CrMoV、WCB、25Cr1MoV 等,以满足耐高温、耐高压和耐腐蚀的性能需求。

阀杆材料:一般采用铬不锈钢、铬钼铝钢等,如 40Cr、12Cr1MoV 等,经过特殊处理后,具有良好的强度、硬度和耐腐蚀性,确保在高温高压环境下正常工作。

密封材料:阀瓣与阀座的密封面采用硬质合金,如司太立合金,填料通常选用柔性石墨等耐高温、耐高压的材料,具有良好的密封性能和抗老化性能,能够适应阀门在长期使用过程中的密封性。

高温高压截止阀性能特点:

耐高温高压:能够承受高温高压的工作环境,适用于各种高温高压的管道系统,如石油、化工、电力、冶金等行业的蒸汽、油品、水等介质的输送。

密封性好:密封面间摩擦力小,依靠阀杆压力使阀瓣与阀座紧密贴合,密封性能优良,有效防止介质泄漏,确保系统的安全运行。

结构简单:整体结构相对简单,制造和维修比较方便,降低了生产成本和维护难度,便于用户进行安装、调试和日常维护。

工作行程小:阀瓣的开启高度一般为公称直径的 25%~30% 时,流量已达到通径尺寸,即阀门已达全开位置,启闭时间短,能够快速实现截断或接通介质的功能。

高温高压截止阀应用领域:

石油和天然气行业:用于管道系统中控制流体的流动,实现流体的切断或调节,承受较高的压力。

化工行业:在化工生产过程中,用于各种腐蚀性或磨蚀性流体的控制,适应高压和腐蚀性环境。

发电行业:特别是火电厂和核电站,用于高温、高压管路上,控制锅炉进水、蒸汽和其他流体的流动。水处理和供水行业:用于控制水流,实现流量调节和压力控制,满足水质要求。

制药和生物技术行业:因其结构简单、易于清洁和消毒的特点,满足对流体控制系统的卫生和无菌条件的严格要求。

高温高压截止阀操作与维护:

安装要求:手轮、手柄操作的截止阀可安装在管道的任何位置上,但手轮、手柄及传动机构不允许作起吊用,介质的流向应与阀体所示箭头方向一致。

操作方式:有手动、齿轮传动、电动等多种操作方式,可根据实际需求进行选择。电动截止阀通常配有相应的电动装置,可实现远程控制和自动化操作。

维护要点:定期检查阀门的密封性能、阀杆的磨损情况以及填料的老化程度,及时更换损坏的部件,确保阀门的正常运行。同时,对阀门进行清洁和润滑,以减少摩擦,延长使用寿命。

Structural Design of High-temperature High-pressure Globe Valve:

Valve Body Structure: It is usually manufactured by casting forging processes, featuring high strength good sealing performance. The shape of the valve body varies according to different types, common ones include straight-through type, right-angle type, DC type oblique globe valve. The inner cavity is designed to be smooth to reduce fluid resistance.

Disc Seat: The disc is the opening closing part of the globe valve. The sealing surface is flat conical, it closely cooperates with the seat to achieve sealing. The disc moves linearly along the centerline of the fluid, the seat is fixed on the valve body. Its sealing surface is usually made by surfacing hard alloy, such as Stellite cobalt-based hard alloy, which has the characteristics of wear resistance, high-temperature resistance, good anti-scuffing performance, long service life.

Stem Handwheel: The movement forms of the stem include the rising stem type the rising rotating stem type. The stem is quenched tempered surface nitrided, good corrosion resistance anti-scuffing performance. It connects the disc the handwheel. By rotating the handwheel, the stem moves up down, thus controlling the opening closing of the disc.

Sealing Structure: A pressure self-tightening sealing structure is adopted. As the medium pressure increases, the sealing performance becomes better. In addition, the depth of the stuffing box of the valve cover is reasonable, a corrosion inhibitor is added to the packing, further ensuring reliable sealing preventing the leakage of the medium.

Working Principle of High-temperature High-pressure Globe Valve:

Relying on the pressure of the stem, the sealing surface of the disc is closely attached to the sealing surface of the seat to prevent the flow of the medium, thus realizing the shut-off function. When the medium enters the valve cavity below the disc, the operating force needs to overcome the friction between the stem the packing the thrust generated by the medium pressure. The closing force of the valve is greater than the opening force. After the self-sealing valve appears, the direction of the medium flow is changed to enter the valve cavity above the disc. At this time, the closing force of the valve is small, the opening force is large, the diameter of the stem can be reduced accordingly, the sealing performance of this type of valve is better.

Material Selection of High-temperature High-pressure Globe Valve:

Valve Body Material: According to different operating conditions medium requirements, materials such as cast steel, carbon steel, alloy steel, stainless steel can be selected, such as ZG20CrMoV, WCB, 25Cr1MoV, etc., to meet the performance requirements of high-temperature resistance, high-pressure resistance, corrosion resistance.

Stem Material: Generally, chrome stainless steel, chrome-molybdenum-aluminum steel, etc. are used, such as 40Cr, 12Cr1MoV, etc. After special treatment, they have good strength, hardness, corrosion resistance, ensuring normal operation in a high-temperature high-pressure environment.

Sealing Material: The sealing surfaces of the disc the seat use hard alloy, such as Stellite alloy. The packing usually selects materials with high-temperature resistance high-pressure resistance, such as flexible graphite, which has good sealing performance anti-aging performance can ensure the sealing performance of the valve during long-term use.

Performance Characteristics of High-temperature High-pressure Globe Valve:

High-temperature High-pressure Resistance: It can withstand the working environment of high temperature high pressure is suitable for various high-temperature high-pressure pipeline systems, such as the transportation of media like steam, oil products, water in industries such as petroleum, chemical, electric power, metallurgy.

Good Sealing Performance: The friction between the sealing surfaces is small. Relying on the pressure of the stem, the disc is closely attached to the seat, the sealing performance is excellent, effectively preventing the leakage of the medium ensuring the safe operation of the system.

Simple Structure: The overall structure is relatively simple, the manufacturing maintenance are relatively convenient, reducing the production cost maintenance difficulty, facilitating the installation, debugging, daily maintenance by users.

Small Working Stroke: When the opening height of the disc is generally 25% to 30% of the nominal diameter, the flow rate has reached the maximum, that is, the valve has reached the fully open position. The opening closing time is short, it can quickly realize the function of cutting off connecting the medium.

Application Fields of High-temperature High-pressure Globe Valve:

Petroleum Natural Gas Industry: It is used to control the flow of fluid in the pipeline system, realize the cutting off regulation of the fluid, withstand relatively high pressure.

Chemical Industry: In the chemical production process, it is used to control various corrosive abrasive fluids adapt to high-pressure corrosive environments.

Power Generation Industry: Especially in thermal power plants nuclear power plants, it is used on high-temperature high-pressure pipelines to control the flow of boiler feed water, steam, other fluids.

Water Treatment Water Supply Industry: It is used to control the water flow, realize flow regulation pressure control, meet the water quality requirements.

Pharmaceutical Biotechnology Industry: Due to its simple structure, easy cleaning, disinfection characteristics, it meets the strict requirements for the hygiene sterility conditions of the fluid control system.

Operation Maintenance of High-temperature High-pressure Globe Valve:

Installation Requirements: The globe valve operated by a handwheel handle can be installed at any position on the pipeline, but the handwheel, handle, transmission mechanism are allowed to be used for lifting. The flow direction of the medium should be consistent with the arrow direction indicated on the valve body.

Operation Mode: There are various operation modes such as manual, gear drive, electric, the selection can be made according to actual needs. The electric globe valve is usually equipped with a corresponding electric device, which can realize remote control automatic operation.

Maintenance Key Points: Regularly check the sealing performance of the valve, the wear condition of the stem, the aging degree of the packing, replace the damaged parts in a timely manner to ensure the normal operation of the valve. At the same time, clean lubricate the valve to reduce friction extend the service life.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!