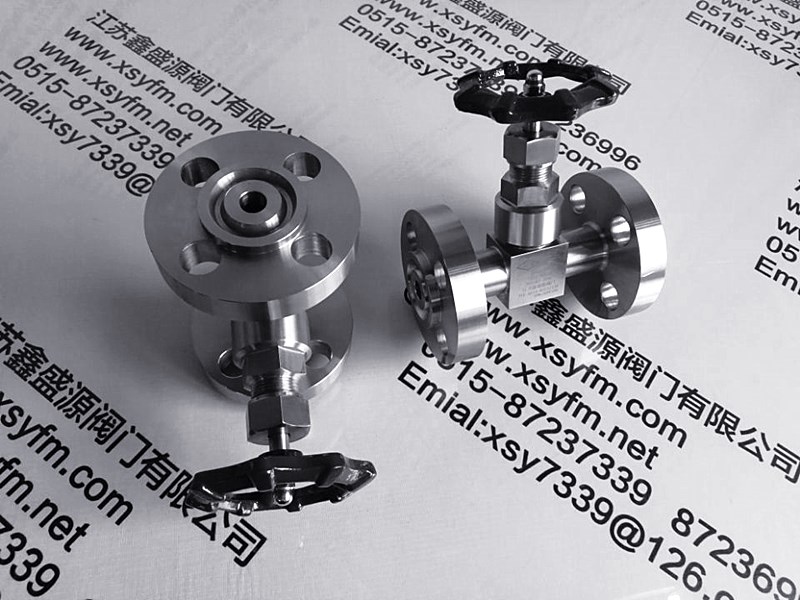

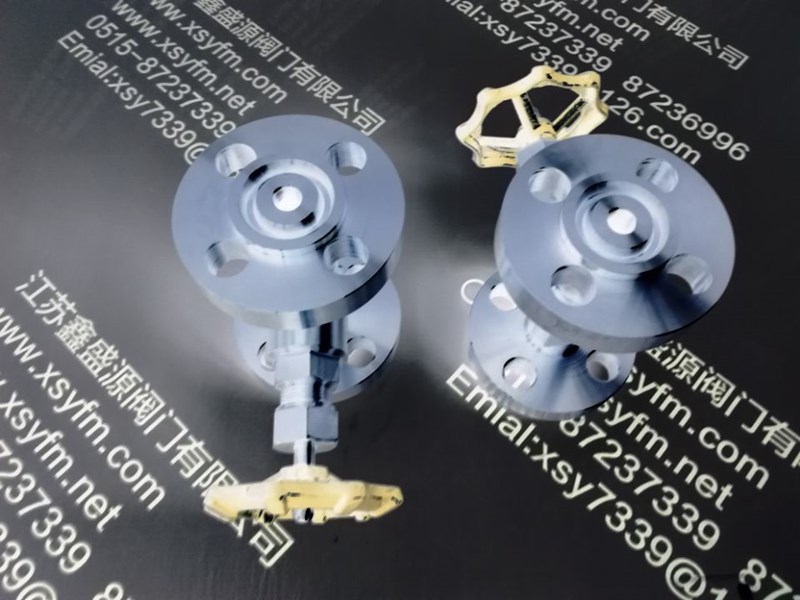

高压法兰闸阀

高压法兰闸阀是专门设计用于承受极高压力工况的法兰连接闸阀。通常指用于公称压力PN100(Class 600)及以上等级管道系统的闸阀。其采用特殊的结构设计、好材料的制造工艺,确保阀门在高压、高温、高冲击等极端条件下仍能实现稳定密封和稳定操作,是石油、天然气、化工、电力、军事等行业关键高压装置中的核心切断设备。

高压法兰闸阀主要特点

1. 极高的承压能力:阀体通常采用好的合金钢锻造而成,壁厚经过准确计算和加强设计,能安全承受数十兆帕甚至上百兆帕的内部压力。

2. 高压法兰闸阀增强的密封系统:

· 阀座密封:采用硬质合金(如司太立Stellite)堆焊或整体烧结的阀座,形成超硬的金属密封副,耐磨、耐冲刷、耐高温。

· 阀杆密封:采用多道柔性石墨填料或增强型PTFE填料,并配有碟形弹簧自紧式填料压盖,确保在压力波动下阀杆密封的长期有效性。

· 中法兰密封:使用金属缠绕垫片或齿形垫片,让阀体与阀盖连接处在高压下的密封稳定性。

3. 高压法兰闸阀刚性结构设计:采用刚性楔式闸板或弹性闸板,避免在高压下因变形而导致的卡阻或泄漏。阀盖通常采用压力自紧式密封结构或螺栓连接式,结构更稳固。

4. 操作力矩大:为应对高压介质对闸板产生的巨大推力,通常配备推力轴承和加长杆伞齿轮传动装置,以明显减小操作力矩,实现轻松启闭。

5.高压法兰闸阀 严格的材料与检验:遵循API、ASME、GB等严格标准,材料需进行冲击韧性测试。阀门成品须经过高达1.5倍公称压力的强度试验和1.1倍的密封试验。

典型结构形式

· 高压法兰闸阀压力自紧式阀盖(Pressure Seal Bonnet):这是高压阀门的标志性结构。内部压力越高,阀盖与阀体间的密封力越大,密封效果越好,特别适用于超高压(如Class 1500及以上)工况。

· 螺栓连接阀盖(Bolted Bonnet):适用于中高压力等级(如Class 600 - Class 900),结构成熟稳定。

· 闸板形式:以刚性楔式闸板和弹性闸板为主,确保在高压下的密封贴合度。

高压法兰闸阀主要应用领域

· 石油化工:加氢裂化、加氢精制、高压聚乙烯等装置的反应进料管线。

· 油气开采:井口装置、采油树、高压集输管线。

· 电力工业:电站锅炉的主蒸汽切断阀、给水系统。

· 化肥工业:合成氨、尿素装置的高压管线。

Product Overview of High-Pressure Flange Gate Valve

I. Product Introduction

A High-Pressure Flange Gate Valve is specifically engineered to withstand extremely high-pressure service conditions.It typically refers to gate valves designed for piping systems with nominal pressures of PN100 (Class 600) above. Featuring special structural designs, high-quality materials, advanced manufacturing processes, these valves ensure reliable sealing stable operation under extreme conditions such as high pressure, high temperature, high shock. They serve as critical shut-off devices in key high-pressure units within industries like oil gas, petrochemical, power generation, defense.

Main Features

1. Exceptional Pressure Containment: The body is usually forged high-quality alloy steel, with wall thickness precisely calculated reinforced to safely withstand internal pressures of tens even hundreds of MPa.

2. Enhanced Sealing Systems:

· Seat Sealing: Utilizes hard-faced (e.g., Stellite) fully hardened seats to create ultra-hard metal sealing pairs, resistant to wear, erosion, high temperatures.

· Stem Sealing: Employs multiple rings of flexible graphite reinforced PTFE packing, often with a Belleville spring-loaded gland follower to maintain long-term stem sealing integrity under fluctuating pressures.

· Body-Bonnet Seal: Uses spiral-wound gaskets ring-type joint gaskets to ensure reliability of the body-bonnet joint under high pressure.

3. Rigid Structural Design: Incorporates a solid wedge flexible wedge design to prevent sticking leakage caused by deformation under high pressure. The bonnet often features a pressure-seal bolted design for enhanced stability.

4. High Torque Operation: To counteract the significant thrust on the gate high-pressure media, these valves are typically equipped with thrust bearings an extended stem with a bevel gear operator to drastically reduce operating torque, enabling smooth operation.

5. Stringent Material Testing Standards: Manufactured in compliance with strict standards like API, ASME, GB. Materials undergo impact toughness testing. Finished valves must pass rigorous hydrostatic shell tests (at 1.5x nominal pressure) seat tests (at 1.1x nominal pressure).

Typical Structural Types

· Pressure-Seal Bonnet: A hallmark design for high-pressure valves. The sealing force between the bonnet body increases with internal pressure, making it ideal for ultra-high pressure services (e.g., Class 1500 above).

· Bolted Bonnet: A mature reliable design commonly used for medium to high-pressure classes (e.g., Class 600 - Class 900).

· Gate Design: Primarily solid wedge flexible wedge types are used to ensure optimal sealing contact under high pressure.

Primary Applications

.Petrochemicals: Reactor feed lines in hydrocracking, hydrotreating, high-pressure polyethylene units.

.Oil & Gas Production: Wellhead equipment, Christmas trees, high-pressure gathering pipelines.

· Power Generation: Main steam isolation valves for power station boilers, feedwater systems.

· Fertilizer Industry: High-pressure pipelines in synthetic ammonia urea plants.

高压法兰闸阀核心术语中英对照:

· 高压法兰闸阀:High-Pressure Flange Gate Valve

· 公称压力:Nominal Pressure

· 压力等级:Pressure Class (e.g., Class 600, Class 1500)

· 压力自紧式阀盖:Pressure-Seal Bonnet

· 螺栓连接阀盖:Bolted Bonnet

· 刚性楔式闸板:Solid Wedge

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!