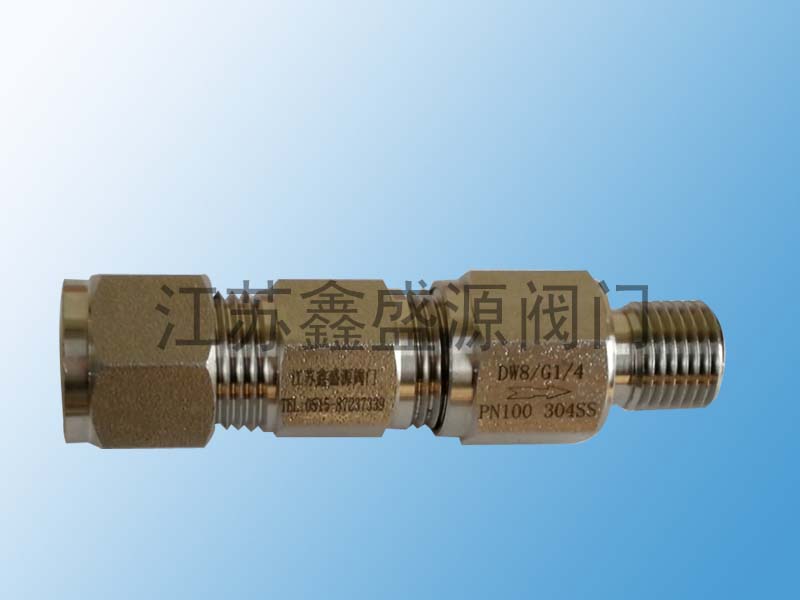

卡套终端止回阀的工作原理是在一个方向流动的流体压力作用下,阀瓣打开;流体反方向流动时,由流体压力和阀瓣的自重合阀瓣作用于阀座,从而切断流动。H91X卡套终端止回阀又称为逆流阀、逆止阀、背压阀、单向阀。这类阀门是靠管路中介质本身的流动产生的力而自动开启和关闭的,属于一种自动阀门。止回阀用于管路系统,其主要作用是防止介质倒流、防止泵及其驱动电机机反转,以及容器内介质的泄放。H91X卡套终端止回阀是通过一端卡套连接另外一端螺纹连接,具有安装方便 连接牢固 方便更换等优点。卡套形式又分为双卡套和单卡套2种,螺纹可以根据要求做成内螺纹或者外螺纹。螺纹形式用户可根据各自情况选购。

卡套终端止回阀

卡套终端止回阀是一种专为管路终端或支线末端设计的特殊止回阀,其采用卡套式连接,便于快速安装和拆卸。它集成了止回功能与终端堵头的作用,不仅能防止介质倒流,还能在检修或系统测试时方便地排放或连接设备。

卡套终端止回阀通常为弹簧辅助的升降式止回阀。在系统压力下,介质顶开阀芯,实现流动;当上游压力下降或消失时,弹簧力迅速推动阀芯复位,密封阀口,防止介质回流。其末端的卡套接口(通常是阴螺纹或快插接头)可以连接压力表、传感器、软管或用作排放口。

卡套终端止回阀主要特点:

终端设计: 专为管路末端设计,提供密封和连接点,一阀多用。

卡套式连接: 安装简便快捷,无需复杂的焊接或螺纹密封作业,维护方便。

卡套终端止回阀弹簧加载: 内置弹簧确保快速响应和紧密关闭,即使在安装位置多变(如水平、垂直向上/向下)或低压工况下也能稳定工作。

卡套终端止回阀紧凑结构: 体积小,重量轻,节省空间,非常适合在紧凑的液压和气动系统中使用。

卡套终端止回阀排放/测压功能: 末端口可用于系统排气、介质取样、连接仪表或临时排放,功能灵活。

卡套终端止回阀密封稳定: 金属与软密封材料(如PTFE、NBR)的组合,确保阀芯密封和卡套接口处的零泄漏。

卡套终端止回阀多种材质: 阀体、阀芯和弹簧可根据介质(液压油、润滑油、压缩空气、水等)特性选用碳钢、不锈钢、黄铜等材料。

卡套终端止回阀典型应用:

广泛应用于液压系统测试点、润滑系统支线末端、气动工具供气管路、压缩机系统、冷却系统以及各种工业设备中需要终端密封、测压、取样或防止卸荷时介质倒流的场合。

Sleeve-Type End Check Valve Product Overview

The Sleeve-Type End Check Valve is a specialized check valve designed for pipeline terminals branch line ends. It features a sleeve-type ( compression fitting) connection for quick installation disassembly. It combines the check function with the role of an end cap, only preventing media backflow but also facilitating media discharge equipment connection during maintenance system testing.

This valve is typically a spring-assisted poppet check valve. Under system pressure, the media pushes the poppet open to allow flow. When the upstream pressure drops ceases, the spring force promptly returns the poppet to its seat, sealing the port preventing backflow. Its end port (usually a female thread quick-connect coupling) can be used to connect pressure gauges, sensors, hoses, serve as a drain point.

Key Features:

End-Port Design: Specifically designed for pipeline terminals, providing both sealing a connection point, making it a multi-functional component.

Sleeve-Type Connection: Simple quick installation, eliminating the need for complex welding thread sealing procedures, facilitating easy maintenance.

Spring-Loaded: The internal spring ensures fast response tight sealing, enabling reliable operation even in various installation orientations (horizontal, vertical up/down) under low-pressure conditions.

Compact Structure: Small size light weight save space, making it ideal for use in compact hydraulic pneumatic systems.

Bleeding/Testing Function: The end port can be used for system venting, media sampling, instrument connection, temporary drainage, offering flexible functionality.

Reliable Sealing: A combination of metal soft sealing materials (e.g., PTFE, NBR) ensures zero leakage at both the poppet seal the sleeve connection interface.

Various Materials: The body, poppet, spring can be manufactured materials like carbon steel, stainless steel, brass to suit different media properties (hydraulic oil, lubricant, compressed air, water, etc.).

Typical Applications:

Widely used at test points in hydraulic systems, at the ends of lubrication system branches, in pneumatic tool supply lines, compressor systems, cooling systems, various industrial equipment requiring terminal sealing, pressure testing, sampling, prevention of media backflow during unloading.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!