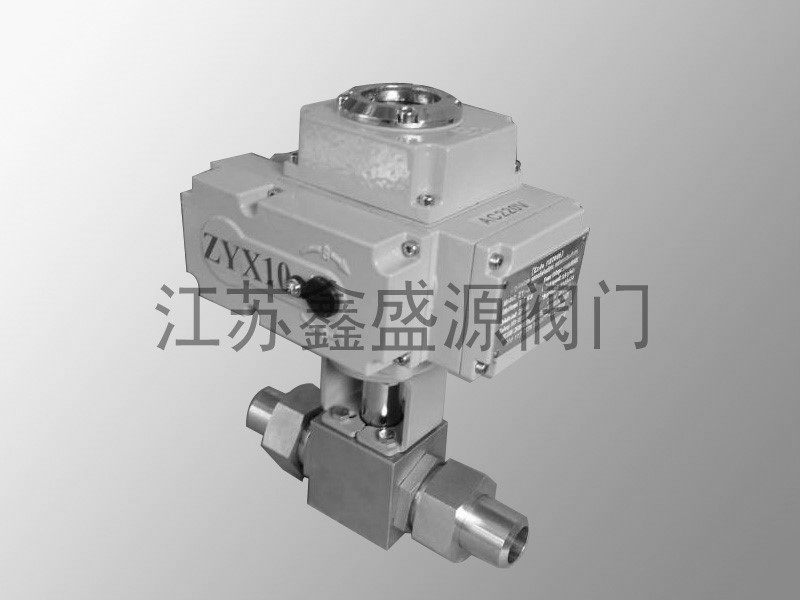

Q921N电动高压球阀,此球阀的执行机构是全电子式电动执行机构,采有机电一体化结构,具有机内伺服操作和开度信号位置反馈、位置指示、手动操作等功能,功能强、性能稳定、连线简单。在工作方面有了很大的提高和改善,防爆型电动球阀用途在工作方面有了很大的提高和改善,可以广泛应用于石油、化工、水处理、造纸、电站、供热、轻工等各行业中。

Q921N电动高压球阀优点:

1、壳体:壳体为硬质铝合金,经阳极氧化处理和聚酯粉末涂层,耐腐蚀性强,防护等级为IP67。

2、电机:全封闭式鼠笼式电机,体积小,扭距大,惯性力小,绝缘等级为F级,内置热保护开关,可防止损坏电机。

3、手动结构:手轮的设计保持安全稳定、省力、体积小。不通电时,扳动离合器手柄可进行手动操作。

4、指示器:指示器安装在中心轴上,采用凸出镜设计,不积水,观察方便。

5、干燥器:可防止由于温度和天气变化导致执行器内部水分凝结,保持内部电气元件的干燥。

6、限位开关:机械、电子双重限位。旋转螺钉即可调整机械限位,安全稳定;凸轮机构来控制电子限位开关,调整机构调整简单,定位。

7、扭距开关:可提供过载保护,防止损坏电机。

8、自锁:采用精密的双蜗轮蜗杆机构,传输效能,扭距大,效率高,噪音低(50分贝以下),防止反转,传动部分稳定,无需再加油。

9、蜗轮:采用凹轮设计确保与蜗杆的接触面大,传输扭距大,平衡且耐磨,寿命长。当然此球阀的驱动方式和连接方式不仅仅只局限于蜗轮,还有法兰式、手动式等。

电动高压球阀

电动高压球阀是一种专为高压力管路系统设计的自动化阀门,主要由电动执行机构和高压球阀阀体两部分组成。其核心特点是阀体通常采用锻钢材料及强化结构设计,使其能够承受通常PN10.0 MPa及以上的高压环境。

电动高压球阀工作时,它通过接收控制系统的电源或信号(如直接开关信号或4-20mA调节信号),驱动电机带动球阀的球体旋转90度,从而快速接通或切断管道中的介质。部分阀门采用固定球球阀结构,并带有浮动阀座,受介质压力后,阀座产生移动,使密封圈紧压在球体上,以保持密封,这种结构操作扭距小,适用于高压和大口径的阀门。由于其高压耐受性和稳定性,被广泛应用于石油、化工、天然气、冶金等行业的特殊工况场合。

电动高压球阀主要结构与特点

· 电动高压球阀阀体与内部结构:阀体常采用三段式锻造阀体结构。阀芯为O型球体,实现流体的切断。部分阀门采用固定球球阀结构,并带有浮动阀座,受介质压力后,阀座产生移动,使密封圈紧压在球体上,以保持密封,这种结构操作扭距小,适用于高压和大口径的阀门。为提高抗冲蚀磨损的能力,阀体和球体等关键部件通常采用硬度高、屈服点高、疲劳强度高的材料,并可能经过热处理和表面硬化处理。密封材料根据介质和温度选择,如PTFE、合金、POM、对位聚苯或金属硬密封材料。

· 电动高压球阀电动执行机构:电动执行器采用一体式结构,内置伺服系统,无须另配伺服放大器,以单相电源AC220V、AC380V或直流电源24VDC等即可控制运转。执行机构通常提供开关型和调节型两种控制方式。部分执行器具备过热保护、过载保护、电气和机械二重限位等保护装置,并可能配有手动操作结构(如手轮或机械离合机构),在断电时可进行手动操作。

· 电动高压球阀主要特点总结:具备很好的耐高压性能,锻件在工作压力下能保持良好的密封性能及抗压均匀性。密封稳定,流通能力大,流阻小。开关迅速,只需旋转90度即可快速启闭。流向可任意,部分阀门设计为双向密封。使用寿命长,稳定性高。可实现远程控制和自动化操作。

电动高压球阀主要技术参数

项目 参数/描述

公称通径 (Nominal Diameter) DN15 ~ DN300mm

公称压力 (Nominal Pressure) 常见 PN10.0, 16.0, 20.0, 25.0, 32.0, 42.0 MPa

电动高压球阀连接方式 (Connection Type) 法兰式、螺纹连接(内螺纹或外螺纹),对焊或承插焊

电源电压 (Power Supply) AC110V、AC220V、AC380V,DC24V等

动作范围 (Action Range) 0~90°

电动高压球阀控制方式 (Control Mode) 开关切断式(两位开关控制)、智能调节型(4-20mA模拟信号控制)

适用温度 (Applicable Temperature) 阀体材质和密封材料决定,例如 -29℃ ~ +180℃,或 -20℃ ~ +200℃ 等

适用介质 (Applicable Media) 水、蒸汽、油品、气体、腐蚀性介质(如酸碱)等

阀体材质 (Body Material) 碳钢WCB、不锈钢304、316、316L等

泄漏量 (Leakage) 按GB/T4213-92,小于额定KV0.01%

电动高压球阀类型与应用领域

· 主要类型:根据阀体结构,主要分为电动内螺纹高压球阀和电动法兰高压球阀。根据球体结构,有浮动球、固定球等类型,其中固定球结构更常见于高压场合。

· 电动高压球阀典型应用领域:广泛应用于石油和天然气行业(如含硫化氢介质、杂质多、腐蚀严重的天然气长输管线)。化工行业(如高压反应釜、硫酸、液氨等腐蚀性介质的高压输送)。冶金、造纸、电力等行业。污水处理和环保处理系统。

电动高压球阀电动高压球阀完整英文翻译

Product Overview of Electric High-Pressure Ball Valve

The Electric High-Pressure Ball Valve is an automated valve specially designed for high-pressure pipeline systems, mainly composed of an electric actuator a high-pressure ball valve body . Its core feature is that the valve body is typically made of forged steel material with a reinforced structure, enabling it to withstand high-pressure environments, typically PN10.0 MPa above .

During operation, it receives power signals the control system (such as direct on/off signals 4-20mA control signals) to drive the motor, which rotates the ball by 90 degrees, thereby quickly connecting cutting off the medium in the pipeline . Some valves use a fixed ball structure with floating seats; when subjected to media pressure, the seat moves, pressing the sealing ring against the ball to ensure sealing. This structure has low operating torque is suitable for high-pressure large-diameter valves . Due to its high-pressure tolerance reliability, it is widely used in special working conditions in industries such as petroleum, chemical, natural gas, metallurgy .

Main Structure Features

· Valve Body Internal Structure: The body often uses a three-piece forged structure . The valve core is an O-type sphere for flow shutoff . To improve resistance to erosion wear, key components like the body ball are usually made of materials with high hardness, high yield point, high fatigue strength, may undergo heat treatment surface hardening processes . The sealing material is selected based on the medium temperature, such as PTFE, alloy, POM, poly-phenol, metal hard sealing materials .

· Electric Actuator: The electric actuator often adopts an integrated structure with a built-in servo system, requiring no additional servo amplifier. It can operate with power supplies like single-phase AC220V, AC380V, DC24VDC . The actuators typically offer two control modes: Switch Type Regulating Type . Some actuators are equipped with protection devices like thermal protection, overload protection, dual mechanical electrical limit switches. They may also feature a manual operation structure (e.g., handwheel mechanical clutch mechanism) for manual operation during power loss .

· Key Features Summary: Offers excellent high-pressure resistance; forged parts maintain good sealing performance pressure resistance uniformity under maximum working pressure . Reliable sealing, large flow capacity, low flow resistance . Rapid opening closing, requiring only a 90-degree rotation . Flow direction can be arbitrary; some valves are designed for bidirectional sealing . Long service life high reliability . Enables remote control automated operation .

Main Technical Parameters

The table below lists typical technical parameters (Please note that specific values may vary depending on the model, manufacturer, application):

Item Parameter/Description

Nominal Diameter DN15 ~ DN300mm

Nominal Pressure Common PN10.0, 16.0, 20.0, 25.0, 32.0, 42.0 MPa

Connection Type Flanged, Threaded (Internal External), Butt Welding Socket Welding

Power Supply AC110V, AC220V, AC380V, DC24V, etc.

Action Range 0~90°

Control Mode Switch Type (On/Off control), Intelligent Regulating Type (4-20mA analog signal control)

Applicable Temperature Depends on body material seal material, e.g., -29℃ ~ +180℃, -20℃ ~ +200℃, etc.

Applicable Media Water, Steam, Oil products, Gas, Corrosive media (e.g., acid, alkali), etc.

Body Material Carbon Steel WCB, Stainless Steel 304, 316, 316L, etc.

Leakage According to GB/T4213-92, less than 0.01% of rated KV

Types Application Fields

· Main Types: According to the valve body structure, they are mainly divided into Electric Internal Thread High-Pressure Ball Valves Electric Flanged High-Pressure Ball Valves . Based on the ball structure, there are floating ball fixed ball types, with the fixed ball structure being more common in high-pressure applications .

· Typical Application Fields: Widely used in the Petroleum Natural Gas Industry (e.g., natural gas pipelines with H₂S media, many impurities, severe corrosion) . Chemical Industry (e.g., high-pressure reactors, high-pressure transportation of corrosive media like sulfuric acid liquid ammonia) . Metallurgy, Paper Making, Power Generation industries . Wastewater Treatment Environmental Protection systems .

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!