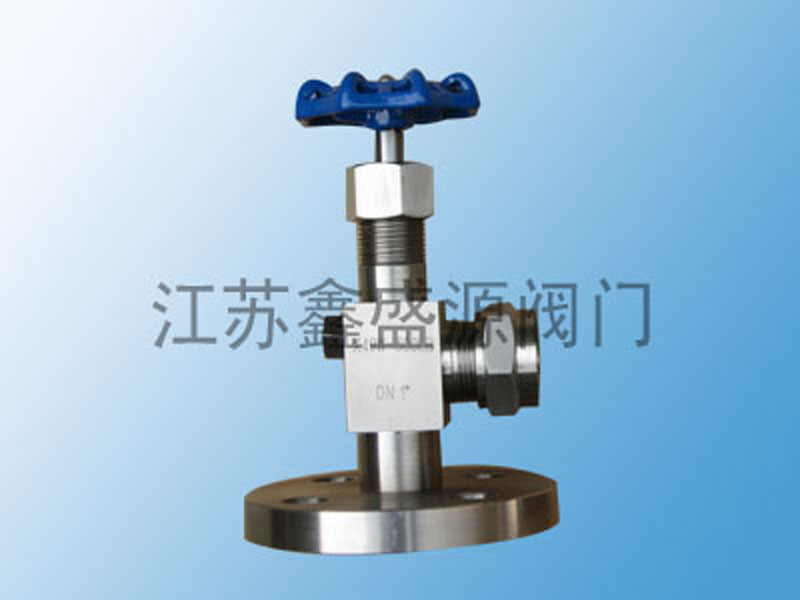

JX49液位计针型阀产品特性:

液位计针型阀JX49H_JX49W为法兰连接,阀瓣为旋塞提升,锥面密封;公称压力≤10000Psi,工作温度适合-29℃~+250℃;JX49W/H液位计针形(型)截止阀广泛使用于水、油、气等腐蚀性与非腐蚀性介质

JX49液位计针型阀详细介绍:

JX49W型法兰液位计,JX29W、JX49W液位计阀门,也叫液位计阀门,液位计考克,主要在液位计的控制管道中应用、大石化工程、工业锅炉工程、化工工程、机电工程大量应用。主要为一端为法兰连接,一端为螺纹式,密封一般为聚四氟密封,法兰可以根据客户的要求定做,压力1.6MPA。

手柄方式:手轮式,条钢式,有红色,蓝色,黑色,黄色

设计制造:GB/T12224-1989,JB/T7747-1995

连接方式:卡套式,内螺纹式,外螺纹式

结构特征:一端内螺纹式,一端法兰式

阀门检验:GB/T13927-1992

JX49 液位计针型阀

JX49系列是一款专为液位计(如玻璃板液位计、磁性翻板液位计等)配套设计的高性能针型阀。其主要功能是控制液位计与设备本体之间的流体通道,充当液位计的“开关”和“安全屏障”。

该阀采用针形阀芯设计,通过精密螺纹旋转来实现流体的细微调节和稳定切断。其关键作用在于实现液位计的在线隔离、排污冲洗、安全维护和流量控制,是让液位测量系统安全、稳定、灵活运行的关键附件。

JX49 液位计针型阀主要特点:

精密调节: 针形阀芯可实现流量的细微调节,避免液位计因流体冲击而损坏。

密封稳定: 采用金属硬密封或软密封材料,确保阀门在关闭状态下无泄漏,安全性能高。

结构紧凑: 体积小,安装方便,适用于空间有限的安装位置。

连接多样: 通常提供法兰式、螺纹式(内螺纹、外螺纹、焊接式)等多种连接方式,以适配不同的设备接口。

安全维护: 在液位计需要检修、更换或冲洗时,可关闭此阀以隔离设备内的介质,实现不停车操作,保障生产安全。

承压能力强: 设计用于高压工况,与液位计本体承压等级相匹配。

JX49 液位计针型阀典型应用:

广泛应用于石油、化工、制药、电力等行业中各种压力容器、锅炉、塔器、储罐上的液位计配套管路。

JX49 Level Gauge Needle Valve Product Overview

The JX49 series is a high-performance needle valve specifically designed for use with level gauges (such as glass level gauges, magnetic level indicators, etc.). Its primary function is to control the fluid passage between the level gauge the vessel, acting as the "on/off switch" "safety barrier" for the gauge.

This valve features a tapered needle-shaped plunger that precisely mates with a seat. Operation via a fine-threaded stem allows for precise flow regulation reliable shut-off. Its key role is to enable online isolation, blowdown, flushing, safe maintenance, flow control for the level gauge, making it a critical accessory for ensuring the safe, reliable, flexible operation of level measurement systems.

Key Features:

Precise Regulation: The needle-shaped plunger allows for fine flow adjustment, protecting the level gauge damage caused by fluid shock.

Reliable Sealing: Utilizes metal-to-metal hard sealing soft sealing materials to ensure zero leakage in the closed position, offering high safety performance.

Compact Design: Small size for easy installation, suitable for spaces with limited access.

Various Connections: Typically available in multiple end connections such as flanged, threaded (NPT, BSP, etc.), socket weld to accommodate different vessel nozzles.

Safe Maintenance: Allows the level gauge to be isolated the process media for inspection, replacement, flushing without requiring a system shutdown, ensuring operational safety.

High Pressure Capability: Designed for high-pressure services, with pressure ratings matching those of the associated level gauges.

Typical Applications:

Widely used in piping systems for level gauges on pressure vessels, boilers, columns, storage tanks across various industries including petroleum, chemical, pharmaceutical, power generation.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!