GJ11Y板式超高压截止阀是我公司吸收英国、美国、日本、新加坡等国家近年来仪表阀门结构形式的基础上,自行设计的具有结构小巧、外型美观、性能稳定、使用方便灵活、标准化、通用化程度高,广泛适用于石油、化工、轻工、电力、医药、冶金、航空等装置的自动控制系统中,是目前普遍应用的新一代超高压阀门。

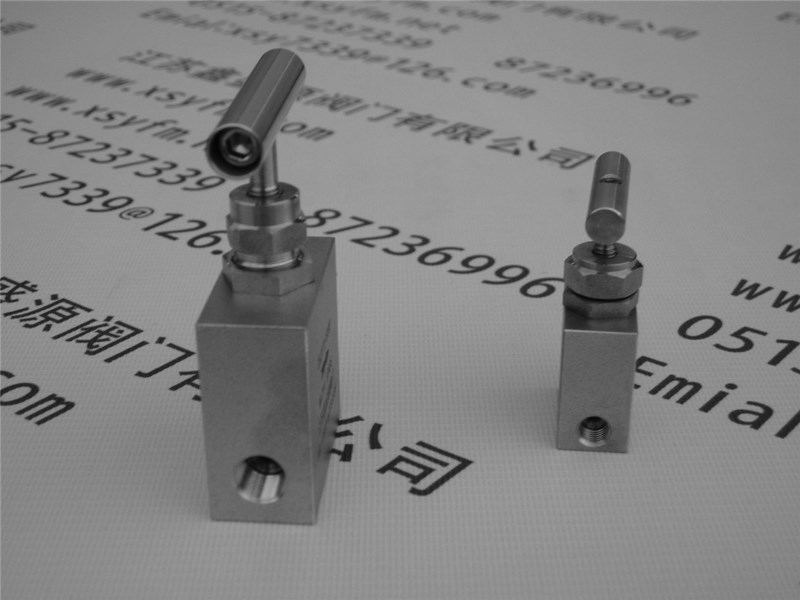

板式超高压截止阀

板式超高压截止阀是一种专为超高压工况设计的阀门,采用板式连接结构,适用于压力超过100MPa的极端环境(如石油开采、化工、超临界流体系统等)。其核心特点是阀体采用锻造或高强度合金材料,阀瓣与阀座硬密封设计,确保在超高压下仍能稳定切断流体,并具备耐腐蚀性和抗冲击性能。

板式超高压截止阀核心特点:

超高压耐受:设计压力可达150MPa以上,符合API、ASME等严苛标准。

板式超高压截止阀板式连接:法兰或螺纹板式结构,便于安装维护,密封性好。

板式超高压截止阀硬密封技术:碳化钨或司太立合金阀瓣/阀座,耐磨耐冲刷。

板式超高压截止阀零泄漏:金属对金属密封(Metal-to-Metal),适用于危险介质。

板式超高压截止阀紧凑轻量化:优化结构设计,减少高压下的体积膨胀风险。

板式超高压截止阀典型应用:

石油天然气井口设备

超高压水射流(水刀)系统

化工反应釜及管道

军事及航天液压系统

注:可根据具体参数(如压力等级、通径尺寸、材料标准等)补充技术细节。

Flange-Type Ultra-High Pressure Globe Valve Product Overview

The Flange-Type Ultra-High Pressure Globe Valve is specifically engineered for extreme pressure conditions exceeding 100MPa (e.g., oil drilling, chemical processing, supercritical fluid systems). Featuring a flanged threaded plate connection, its forged high-strength alloy body, combined with hard-sealed disc/seat design, ensures reliable fluid shutoff under ultra-high pressure, along with exceptional corrosion impact resistance.

Key Features:

Ultra-High Pressure Resistance: Rated for 150MPa+, compliant with API/ASME standards.

Flange/Plate Connection: Facilitates installation maintenance with superior sealing.

Hard-Seal Technology: Tungsten carbide Stellite-coated disc/seat for wear/erosion resistance.

Zero Leakage: Metal-to-metal sealing for hazardous media.

Compact & Lightweight: Optimized design minimizes volumetric expansion risks.

Typical Applications:

Oil & gas wellhead equipment

Ultra-high pressure waterjet (cutting) systems

Chemical reactors & pipelines

Military/aerospace hydraulic systems

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!