Z41Y锻钢法兰闸阀说明:

闸阀的启闭件是闸板,闸板的运动方向与流体方向相垂直,闸阀只能作全开和全关,不能作调节和节流。闸板有两个密封面,常用的模式闸板阀的两个密封面形成楔形、楔形角随阀门参数而异,通常为50,介质温度不高时为2°52'。楔式闸阀的闸板可以做成一个整体,叫做刚性闸板;也可以做成能产生微量变形的闸板,以改善其工艺性,弥补密封面角度在加工过程中产生的偏差,这种闸板叫做弹性闸板。

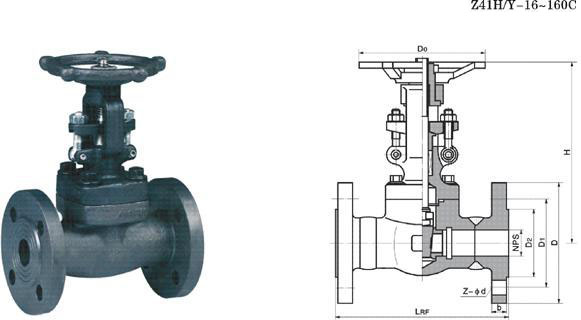

Z41Y锻钢法兰闸阀尺寸:

| 规格DN | 压力 K级 | L | H(开) | W | A | B | C | T | f | n-Ø | 重量(kg) | ||||

| 英制(in) | 公制 | 缩径 | 全径 | 缩径 | 全径 | 缩径 | 全径 | ||||||||

| 1/2 | 15 | 10K | 108 | 166 | 169 | 100 | 100 | 52 | 70 | 95 | 12 | 1 | 4-15 | 4.8 | 5 |

| 20K | 140 | 70 | 95 | 14 | 4-15 | 5.2 | 5.2 | ||||||||

| 40K | 165 | 55 | 80 | 115 | 20 | 4-19 | 6.4 | 6.5 | |||||||

| 3/4 | 20 | 10K | 117 | 169 | 193 | 100 | 125 | 58 | 75 | 100 | 14 | 1 | 4-15 | 5.4 | 5.5 |

| 20K | 152 | 75 | 100 | 16 | 4-15 | 6.5 | 6.6 | ||||||||

| 40K | 190 | 60 | 85 | 120 | 20 | 4-19 | 7.8 | 8 | |||||||

| 1 | 25 | 10K | 127 | 193 | 230 | 125 | 160 | 70 | 90 | 125 | 14 | 1 | 4-19 | 8.6 | 8.8 |

| 20K | 165 | 90 | 125 | 16 | 4-19 | 9.7 | 10.6 | ||||||||

| 40K | 216 | 70 | 95 | 130 | 22 | 4-19 | 11.5 | 12.2 | |||||||

| 11/4 | 32 | 10K | 140 | 230 | 246 | 160 | 160 | 80 | 100 | 135 | 16 | 2 | 4-19 | 13.2 | 14.3 |

| 20K | 178 | 100 | 135 | 18 | 4-19 | 14.5 | 14.5 | ||||||||

| 40K | 229 | 80 | 105 | 140 | 24 | 4-19 | 17.8 | 18 | |||||||

| 11/2 | 40 | 10K | 165 | 246 | 283 | 160 | 180 | 85 | 105 | 140 | 16 | 2 | 4-19 | 14.8 | 15.8 |

| 20K | 190 | 105 | 140 | 18 | 4-19 | 15.9 | 16.2 | ||||||||

| 40K | 241 | 90 | 120 | 160 | 24 | 4-23 | 18.8 | 19 | |||||||

| 2 | 50 | 10K | 178 | 283 | 330 | 180 | 200 | 100 | 120 | 155 | 16 | 2 | 4-19 | 21 | 22.7 |

| 20K | 216 | 120 | 155 | 18 | 4-19 | 25 | 26 | ||||||||

| 40K | 292 | 105 | 130 | 165 | 26 | 4-19 | 29.5 | 30 | |||||||

Z41Y锻钢法兰闸阀

Z41Y锻钢法兰闸阀型号含义解析

首先,“Z41Y”这一型号遵循中国阀门型号编制标准(JB/T 308),其含义如下:

· Z:代表闸阀(Zha Fa)。

· 4:代表连接形式为法兰连接(Fa Lan)。

· 1:代表结构形式为明杆模式闸板(Ming Gan Zhì Ban Shi)。通常指刚性单闸板。

· Y:代表密封面材料为硬质合金(Ying Zhi He Jin)。

因此,Z41Y即表示:明杆法兰式硬质合金密封闸阀。

Z41Y锻钢法兰闸阀是一种应用极为广泛的工业阀门。其阀体、阀盖等主要承压部件采用碳钢或合金钢锻造而成,具备锻造阀门的优良机械性能。该阀门的核心特点是采用明杆结构和硬质合金密封副,使其特别适用于高温、高压、带有微小颗粒或易产生冲刷的苛刻工况,如蒸汽、油气等介质。它是一种高性能的切断阀门。

Z41Y锻钢法兰闸阀主要特点

1. 优异的耐磨与抗冲刷性:阀座密封面采用钴基硬质合金(如司太立Stellite)堆焊或整体烧结而成,闸板密封面也同样进行硬质合金处理。形成的金属硬密封副具有极高的硬度、耐磨性和抗介质冲刷能力,使用寿命远超普通软密封阀门。

2. Z41Y锻钢法兰闸阀明杆结构设计:阀杆随闸板升降而上下移动,其外露的阀杆位置可以直观地显示阀门的开启或关闭状态,便于操作人员观察,有利于安全生产。

3.Z41Y锻钢法兰闸阀可靠的密封性能:通常采用楔式密封原理。关闭时,依靠阀杆向下的推力,使硬质合金闸板与阀座紧密贴合,实现可靠的密封。部分设计可实现双向密封。

4. Z41Y锻钢法兰闸阀良好的高温高压适应性:锻钢材质本身耐高温高压,加上硬密封结构不会因高温而软化失效,因此非常适合蒸汽系统及高温油品管路。

5. Z41Y锻钢法兰闸阀标准的法兰连接:法兰连接尺寸符合GB、HG、JB或ANSI、API等国际标准,便于与各种管道系统集成。

Z41Y锻钢法兰闸阀典型应用

· 电力行业:电站锅炉的主蒸汽、排空、放气等系统。

· 石油化工:油气输送、炼油装置、高温油品及化学介质管路。

· 市政供热:高温高压的蒸汽供热主干线。

· 一般工业:作为需要可靠切断且工况恶劣的通用阀门使用。

Product Overview of Z41Y Forged Steel Flange Gate Valve

I. Model Designation Interpretation

The model"Z41Y" follows the Chinese valve model designation standard (JB/T 308), with the following meaning:

· Z: Represents Gate Valve.

· 4: Represents the connection type as Flange.

· 1: Represents the structure type as Outside Screw Yoke (OS&Y) with a (typically) solid wedge.

· Y: Represents the sealing surface material as Hardalloy (e.g., Stellite).

Therefore, Z41Y translates to: Outside Screw Yoke (OS&Y), Flanged, Hard-Seal Gate Valve.

II. Product Introduction

The Z41Y Forged Steel Flange Gate Valve is an extremely widely used industrial valve.Its main pressure-containing parts, such as the body bonnet, are forged carbon steel alloy steel, endowing it with the superior mechanical properties of forged valves. The key features of this valve are its OS&Y design hard-alloy sealing pairs, making it particularly suitable for demanding applications involving high temperature, high pressure, media with minor particulates prone to erosion, such as steam, oil, gas. It is a high-performance shut-off valve.

III. Main Features

1. Excellent Wear Erosion Resistance: The seat sealing surface is hard-faced with cobalt-based hard alloy (like Stellite) fully hardened. The gate sealing surface receives similar hard-facing treatment. The resulting metal-to-metal hard seal offers exceptional hardness, wear resistance, resistance to media erosion, significantly outperforming soft-sealed valves in service life.

2. Outside Screw Yoke (OS&Y) Design: The stem rises lowers with the gate. The exposed stem position provides a clear visual indication of whether the valve is open closed, facilitating safe operation.

3. Reliable Sealing Performance: Typically employs a wedge sealing principle. When closing, the downward thrust the stem forces the hard-faced gate tightly against the seat, achieving a reliable seal. Some designs allow for bidirectional sealing.

4. Good High-Temperature High-Pressure Capability: The forged steel material itself withstands high temperatures pressures. Combined with the hard seal, which does soften degrade under heat, it is ideal for steam systems high-temperature oil pipelines.

5. Standard Flange Connections: Flange dimensions conform to national (GB, HG, JB) international standards (ANSI, API), ensuring easy integration into various piping systems.

IV. Typical Applications

· Power Generation Industry: Main steam, vent, bleed systems in power plant boilers.

· Petrochemical Industry: Oil gas transmission, refining units, high-temperature oil, chemical media pipelines.

· District Heating Systems: High-temperature high-pressure steam supply mains.

· General Industry: Used as a general-purpose valve reliable shut-off under severe conditions is required.

核心术语中英对照:

· Z41Y锻钢法兰闸阀:Z41Y Forged Steel Flange Gate Valve

· 明杆模式(OS&Y):Outside Screw Yoke (OS&Y)

· 硬质合金:Hard Alloy / Hard-facing Alloy (e.g., Stellite)

· 堆焊:Hard-facing / Overlaying

· 金属硬密封:Metal-to-Metal Seal / Hard Seal

· 楔式密封:Wedge Seal

· 耐磨性:Wear Resistance

· 抗冲刷性:Erosion Resistance / Resistance to Scouring

· 司太立合金:Stellite Alloy

· 型号编制标准:Model Designation Standard

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!