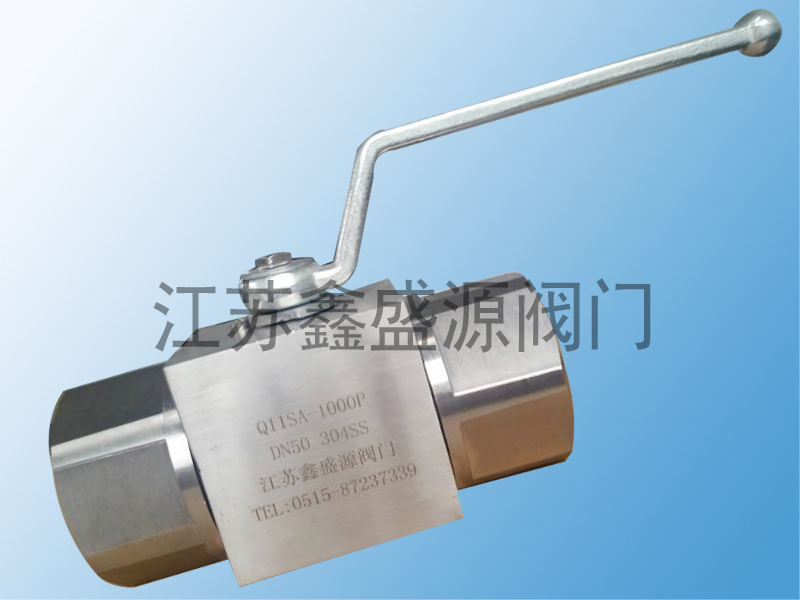

Q11SA内螺纹超高压球阀

Q11SA内螺纹超高压球阀它具有旋转90度的动作,旋塞体为球体,有圆形通孔或通道通过其轴线。球阀在管路中主要用来做切断、分配和改变介质的流动方向,它只需要用旋转90度的操作和很小的转动力矩就能关闭严密。球阀适宜做开关、切断阀使用,但近来的发展已将球阀设计成使它具有节流和控制流量之用,如V型球阀。

Q11SA内螺纹超高压球阀主体及附件都采用锻造加工,采用特殊工艺,合成密封材质,可耐压到200MPa。本身具有结构紧凑,密封稳定,美观大方,维修方便,密封面与球面常在闭合状态,不易被介质冲蚀,易于操作和维修,适用于水、溶剂、酸和天然气等一般工作介质,而且还适用于工作条件恶劣的介质,用于液压机械设备 液压开关 高压水射流 等行业。超高压内螺纹球阀是我公司结合国外技术自行研发的一款全新产品,该产品采用特殊工艺改变了球阀不能耐超高压的技术难题。 Q11SA内螺纹超高压球阀目前可以实现在DN50口径下,耐压可以达到200MPa.是高压清洗 水切割等行业理想的选择。

Q11SA内螺纹超高压球阀优点:

1.流体阻力小,全通径的球阀基本没有流阻。

2.结构简单、体积小、重量轻、耐高压。

3.紧密稳定。它有两个密封面,而且目前球阀的密封面材料广泛使用各种塑料,密封性好,能实现完全密封。在真空系统中也已广泛使用。

4.操作方便,开闭迅速,从全开到全关只要旋转90°,便于远距离的控制。

5.维修方便,球阀结构简单,密封圈一般都是活动的,拆卸更换都比较方便。

6.在全开或全闭时,球体和阀座的密封面与介质隔离,介质通过时,不会引起阀门密封面的侵蚀。

7.适用范围广,通径从小到几毫米,大到几米,从高真空至高压力都可应用。

8.由于球阀在启闭过程中有擦拭性,所以可用于带悬浮固体颗粒的介质中。

超高压内螺纹球阀

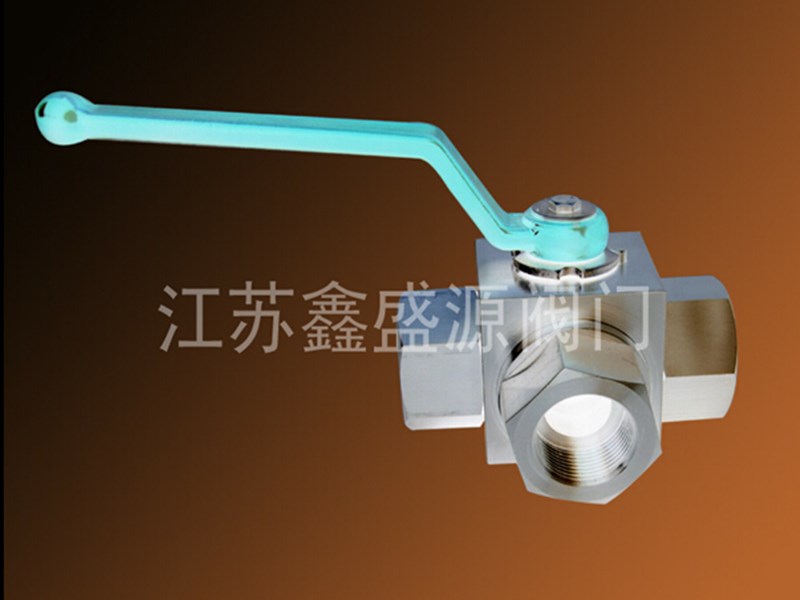

超高压内螺纹球阀是专为超高压流体系统设计的核心控制阀门,核心用于实现高压介质的快速通断与密封控制,广泛适配石油勘探、液压破碎、高压清洗、航空航天等领域,可稳定应对液压油、高压水、压缩气体等介质的极端高压工况。

超高压内螺纹球阀公称压力普遍达63MPa-320MPa(部分特殊型号可达1000MPa),工作温度范围覆盖-40℃-200℃,能耐受极端压力冲击。阀体采用锻制不锈钢(如316、304)或高强度合金材质,经整体锻造与精密加工,结构强度高、抗疲劳性强;球体与阀座采用硬密封结构(如金属对金属密封)或高性能工程塑料密封,配合内螺纹连接(如NPT、G、PT螺纹),密封精度高,可有效杜绝超高压下的介质泄漏。操作方式以手动为主(配备省力式钢质手柄或涡轮传动机构),部分型号支持气动/电动执行器,满足自动化控制需求,尤其适用于超高压管路中空间有限、需精准控制且对密封稳定性要求极高的关键节点。

Ultra-High Pressure Internal Thread Ball Valve

The ultra-high pressure internal thread ball valve is a core control valve designed for ultra-high pressure fluid systems. It is mainly used to realize rapid on-off sealing control of high-pressure media, is widely applicable to fields such as oil exploration, hydraulic breaking, high-pressure cleaning, aerospace. It can stably handle extreme high-pressure working conditions of media like hydraulic oil, high-pressure water, compressed gas.

This type of valve generally has a nominal pressure of 63MPa-320MPa (some special models can reach 1000MPa) an operating temperature range of -40℃-200℃, which can withstand extreme pressure impacts. The valve body is made of forged stainless steel (such as 316, 304) high-strength alloy material, after integral forging precision machining, it has high structural strength strong fatigue resistance. The ball valve seat adopt a hard-seal structure (such as metal-to-metal seal) high-performance engineering plastic seal, are matched with internal thread connections (such as NPT, G, PT threads), which have high sealing precision can effectively prevent medium leakage under ultra-high pressure. The operation method is mainly manual (equipped with a labor-saving steel handle turbine transmission mechanism), some models support pneumatic/electric actuators to meet the needs of automatic control. It is especially suitable for key nodes in ultra-high pressure pipelines that have limited space, require precise control, have extremely high requirements for sealing reliability.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!