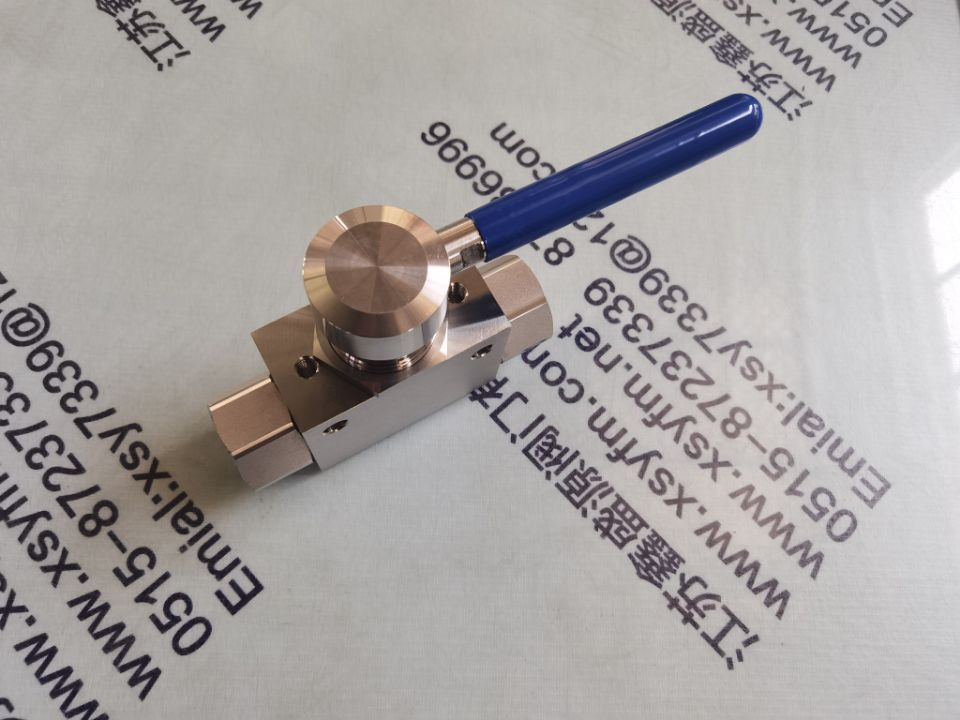

氢站用高压球阀产品概述

氢站用高压球阀是专为氢气站(如加氢站、氢能储存与输送设施)设计的高压流体控制阀门,主要用于氢气的储存、压缩、加注等环节的通断控制,具备适应氢气特性及高压工况的特殊性能,是氢能基础设施中的关键设备。

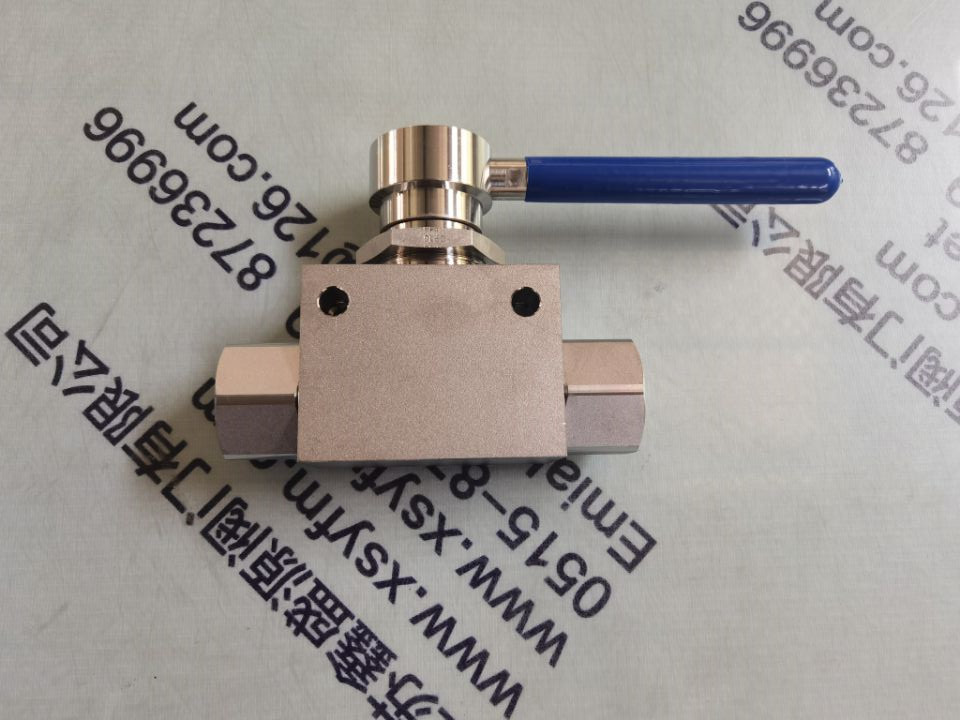

氢站用高压球阀结构设计:

氢站用高压球阀 - 阀体多采用高强度不锈钢(如316L)或特殊合金材料,具备抗氢脆性能和耐腐蚀性,防止氢气渗透导致材料性能劣化。

氢站用高压球阀 - 密封结构采用金属密封或增强型聚合物密封(如改性PTFE),确保在高压下(通常35MPa以上,部分超高压型号达70MPa)的稳定密封,减少氢气泄漏风险。

氢站用高压球阀 - 阀杆采用防吹出设计,配合多重填料密封,提升操作安全性;球体经精密加工,表面光洁度高,减少流阻的同时具有密封面耐磨性。

氢站用高压球阀工作原理:

通过旋转手柄或驱动装置带动阀杆,使球体旋转90°实现阀门的全开或全关。全开时,球体通孔与管道连通,氢气顺畅流通;关闭时,球体阻断流道,依靠球体与阀座的紧密贴合实现密封,精准控制氢气的输送与截止。

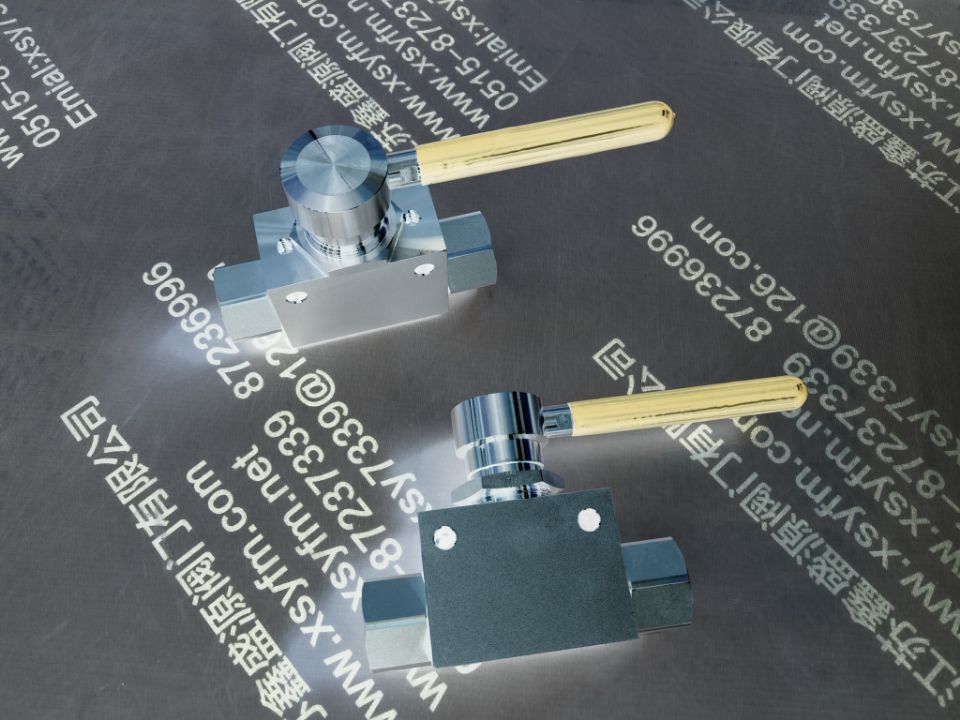

氢站用高压球阀产品特点:

氢站用高压球阀- 抗氢脆与耐高压:材料经过特殊处理,能抵抗氢气在高压下对金属的脆化作用,可长期承受35MPa、70MPa等高压工况。

氢站用高压球阀 - 低泄漏率:密封结构设计符合氢能安全标准,泄漏率极低(通常≤1×10⁻⁶ Pa·m³/s),保障氢站运行安全。

氢站用高压球阀 - 兼容性强:内部流道光滑,减少湍流和压降,适配干燥、洁净的氢气介质,避免杂质污染或化学反应。

氢站用高压球阀 - 操作便捷与安全:支持手动或自动化控制(如气动、电动),开关迅速(1/4圈操作),部分型号配备位置反馈和紧急切断功能。

氢站用高压球阀应用领域:

主要用于加氢站的储氢罐出口、压缩机进出口、加氢机管路、氢气长管拖车连接等关键节点,也适用于氢能发电、燃料电池等领域的高压氢气系统控制。

氢站用高压球阀主要参数:

- 公称压力:35MPa、70MPa(常见),部分可达100MPa;

- 公称通径:DN10 - DN50(根据流量需求选择);

- 适用温度:-40℃ - 80℃(适应不同环境工况);

- 阀体材质:316L不锈钢、哈氏合金等抗氢脆材料;

- 泄漏等级:符合ISO 15848或SAE J2601等氢能行业标准。

Overview of High-Pressure Ball Valves for Hydrogen Stations

High-pressure ball valves for hydrogen stations are specialized fluid control valves designed for hydrogen facilities (such as hydrogen refueling stations, hydrogen storage transportation systems). They are mainly used for on-off control in hydrogen storage, compression, refueling processes, with properties tailored to hydrogen characteristics high-pressure conditions, serving as key equipment in hydrogen energy infrastructure.

Structural Design:

Overview of High-Pressure Ball - The valve body is mostly made of high-strength stainless steel (e.g., 316L) special alloys, featuring excellent hydrogen embrittlement resistance corrosion resistance to prevent material degradation caused by hydrogen permeation.

Overview of High-Pressure Ball - The sealing structure adopts metal seals enhanced polymer seals (e.g., modified PTFE) to ensure reliable sealing under high pressure (usually above 35MPa, with some ultra-high-pressure models reaching 70MPa), reducing the risk of hydrogen leakage.

Overview of High-Pressure Ball - The valve stem uses an anti-blowout design with multiple packing seals to enhance operational safety; the ball is precision-machined with a high surface finish, reducing flow resistance while ensuring wear resistance of the sealing surface.

Working Principle:

The valve is fully opened closed by rotating the handle actuator to drive the valve stem, rotating the ball 90°. When fully open, the ball's through-hole aligns with the pipeline, allowing smooth hydrogen flow; when closed, the ball blocks the flow path, achieving sealing through tight contact between the ball valve seat, precisely controlling hydrogen transportation shut-off.

Product Features:

Overview of High-Pressure Ball - Hydrogen Embrittlement Resistance High-Pressure Tolerance:Materials are specially treated to resist hydrogen-induced embrittlement of metals under high pressure, enabling long-term operation under 35MPa, 70MPa, etc.

Overview of High-Pressure Ball - Low Leakage Rate:The sealing structure meets hydrogen safety standards with extremely low leakage rates (typically ≤1×10⁻⁶ Pa·m³/s), ensuring safe operation of hydrogen stations.

Overview of High-Pressure Ball - Strong Compatibility:Smooth internal flow channels reduce turbulence pressure drop, compatible with dry, clean hydrogen to avoid impurity contamination chemical reactions.

Overview of High-Pressure Ball - Easy Safe Operation:Support manual automated control (e.g., pneumatic, electric) with quick switching (1/4-turn operation); some models are equipped with position feedback emergency shut-off functions.

Application Fields:

Mainly used in key nodes of hydrogen refueling stations, such as outlets of hydrogen storage tanks, compressor inlets/outlets, refueling machine pipelines, connections for hydrogen long-tube trailers. They are also applicable to high-pressure hydrogen systems in hydrogen power generation fuel cell fields.

Main Parameters:

Overview of High-Pressure Ball - Nominal pressure: 35MPa, 70MPa (common), up to 100MPa for some models;

Overview of High-Pressure Ball - Nominal diameter: DN10 - DN50 (selected based on flow requirements);

Overview of High-Pressure Ball - Operating temperature: -40℃ - 80℃ (adapting to different environmental conditions);

Overview of High-Pressure Ball - Valve body material: Hydrogen embrittlement-resistant materials such as 316L stainless steel, Hastelloy;

Overview of High-Pressure Ball - Leakage class: Compliant with hydrogen industry standards like ISO 15848 SAE J2601.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!