YGL21H焊接式直通过滤器是输送介质的管道系统不可缺少的一种过滤装置,通常安装在减压阀、泄压阀、定水位阀或其它设备的进口端,用来清除介质中的杂质,以保护阀门及设备的正常使用。阻力小,排污方便等特点。YGL21H焊接式直通过滤器适用于蒸汽、空气、水、油品等系统管道中,保护各种计量仪器、泵机、阀门、蔬水器等设备。一般通水网为18~30目,通气网为10~100目,通油网为100~480目。过滤器的壳体内部主要由粗滤网、细滤网、吸污管,不锈钢刷或不锈钢吸嘴、密封圈、防腐涂层、转动轴等组成。

YGL21H焊接式直通过滤器说明:

1.适用介质可为水、油、气,

2.过滤高、流通能力大、结构紧凑;

3.结构简单,可在线维修;

4.流通能力大,结构紧凑;密封严密,无气体渗漏;

5.安装省力,经济实惠;

6.连接方式:活接焊接过滤器 对焊过滤器 T型卡套过滤器 法兰过滤器 螺纹过滤器 插焊过滤器 美标过滤器 国标过滤器 蓝式过滤器 Y型过滤器 T型过滤器;

7.适用压力:1.0~100.0MPa

8.适用温度:-196~600℃

YGL21H焊接式直通过滤器维护及保养方法:

①、粗滤过滤器

1、过滤器的核心部位是过滤器芯件,过滤芯由过滤器框和不锈钢钢丝网组成,不锈钢钢丝网属宜损件,需特别保护;

2、当过滤器工作一段时间后,过滤器芯内沉淀了一定的杂质,这时压力降增大,流速会下降,需及时清除过滤器芯内的杂质;

3、清洗杂质时,特别注意过滤芯上的不锈钢钢丝网不能变形或损坏,否则,再装上去的过滤器,过滤后介质的纯度达不到设计要求,压缩机、泵、仪表等设备会遭到破坏;

4、如发现不锈钢钢丝网变形或损坏,需马上更换。

②、精密过滤器

1、精密过滤器的核心部位是过滤滤芯,过滤芯由特殊的材料组成,属宜损件,需特别保护;

2、当精密过滤器工作一段时间后,过滤器滤芯拦载了一定量的杂质,这时压力降增大,流速会下降,需及时清除过滤器内的杂质,同时要清洗滤芯;

3、在清除杂质时,特别注意精密滤芯,不得变形或损坏,否则,再装上去的滤芯,过滤后介质的纯度达不到设计要求;

4、某些精密滤芯,不能多次反复使用,如袋式滤芯、聚丙烯滤芯等;

5、如发现滤芯变形或损坏,需马上更换。

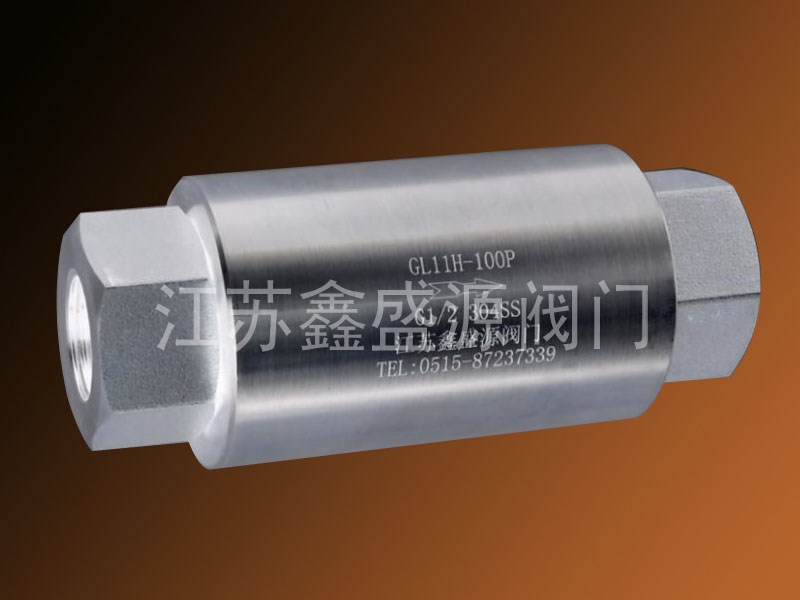

焊接式直通过滤器

焊接式直通过滤器是一种采用焊接方式与管道系统直接连接的过滤设备。其壳体与管道通过焊接成为一体,不可拆卸。其核心部件是内部的滤网(或滤篮),用于拦截和过滤流体中的固体杂质,保护下游的关键设备,如泵、阀门、仪表等。

2. 焊接式直通过滤器主要特点

结构紧凑,密封性好: 采用焊接连接,从根本上杜绝了法兰或螺纹连接可能出现的泄漏问题,密封性能好。

承压高,强度好: 焊接结构使其能承受更高的压力和温度,适用于高压、高温或对密封要求极高的苛刻工况。

无泄漏风险: 没有垫片、密封圈等易损件,避免了因这些部件老化、腐蚀导致的泄漏,安全稳定性高。

维护简便: 虽然壳体不可拆,但通常设计有可开启的排污口或检查盖,便于在线排污。需要清洗或更换滤网时,可通过专门的开口进行操作。

经济耐用: 省去了法兰、螺栓等连接件,初始安装成本可能较高,但长期来看,因其免维护和高稳定性,总体成本较低。

3. 焊接式直通过滤器工作原理

流体从过滤器进口流入,流经内部滤网。滤网会拦截并收集流体中粒径大于其精度的颗粒物(如铁锈、焊渣、管道碎屑等)。清洁的流体则从出口流出,进入下游系统。当滤网积聚的杂质过多导致压差增大时,需进行反冲洗或取出清洗,以恢复其过滤能力。

4. 焊接式直通过滤器应用领域

广泛应用于对密封性和安全性要求极高的行业,例如:

石油化工行业:高温高压的油品、化学品管线。

核电工业:核级管道系统,要求无泄漏。

电力行业:主蒸汽管道、给水系统。

制药行业:高纯度的工艺管道。

其他:易燃、易爆、有毒或贵重介质的输送管道。

Welded Straight-through Strainer Product Overview

1. Product Definition

A Welded Straight-through Strainer is a type of filtration equipment directly integrated into a piping system via welding. Its housing is permanently welded to the pipeline, making it non-detachable. Its core component is an internal screen ( basket), designed to trap remove solid impurities the fluid, thereby protecting downstream critical equipment such as pumps, valves, instruments.

2. Key Features

Compact Structure, Excellent Sealing: The welded connection eliminates potential leakage points inherent in flanged threaded connections, offering superior sealing performance.

High Pressure Resistance Strength: The welded construction allows it to withstand higher pressures temperatures, making it suitable for demanding applications including high-pressure, high-temperature, extreme sealing requirement conditions.

Zero Leakage Risk: The absence of gaskets, seals, other wear-prone components prevents leaks caused by the aging corrosion of these parts, ensuring high safety reliability.

Easy Maintenance: Although the housing is non-detachable, it is typically designed with an openable blow-off port access cover for online cleaning. The screen can be accessed, cleaned, replaced through a dedicated opening.

Economical Durable: It eliminates the need for flanges, bolts, other connecting parts. The initial installation cost might be higher, but the overall lifecycle cost is lower due to minimal maintenance high reliability.

3. Working Principle

Fluid enters the strainer through the inlet passes through the internal screen. The screen intercepts collects particles larger than its mesh size (e.g., rust, weld slag, pipe debris). The cleaned fluid then exits through the outlet proceeds to the downstream system. When accumulated debris causes an excessive pressure drop across the screen, backwashing removal for cleaning is required to restore its filtering capacity.

4. Applications

Widely used in industries with stringent requirements for sealing safety, such as:

Petrochemical Industry: High-temperature high-pressure oil chemical pipelines.

Nuclear Power Industry: Nuclear-grade piping systems requiring absolute leak-tight integrity.

Power Generation Industry: Main steam lines, feedwater systems.

Pharmaceutical Industry: High-purity process piping.

Others: Pipelines transporting flammable, explosive, toxic, precious media.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!