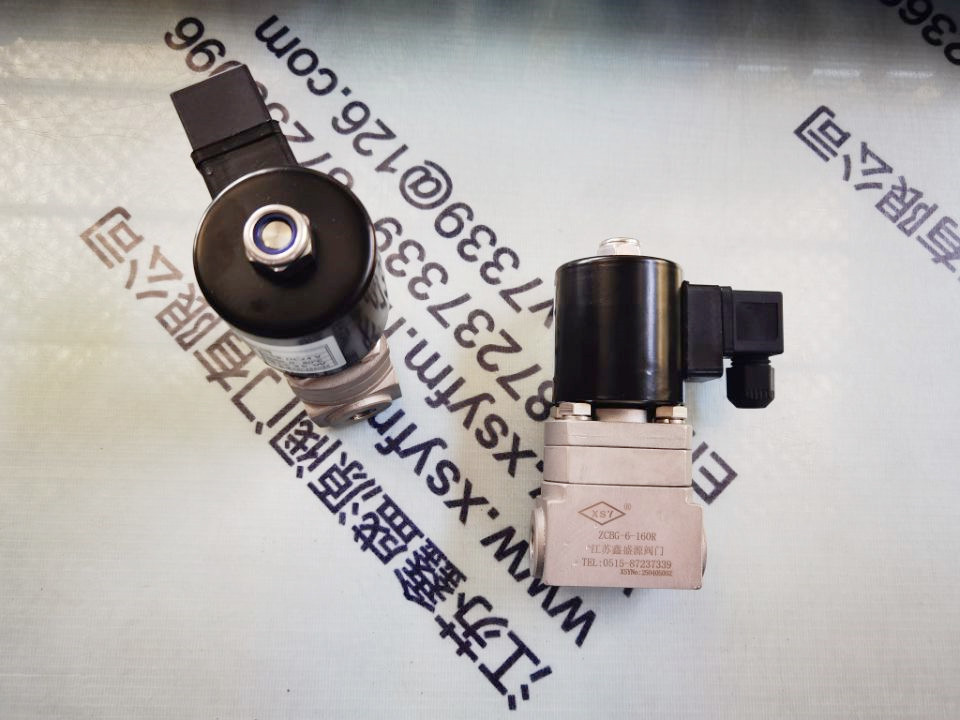

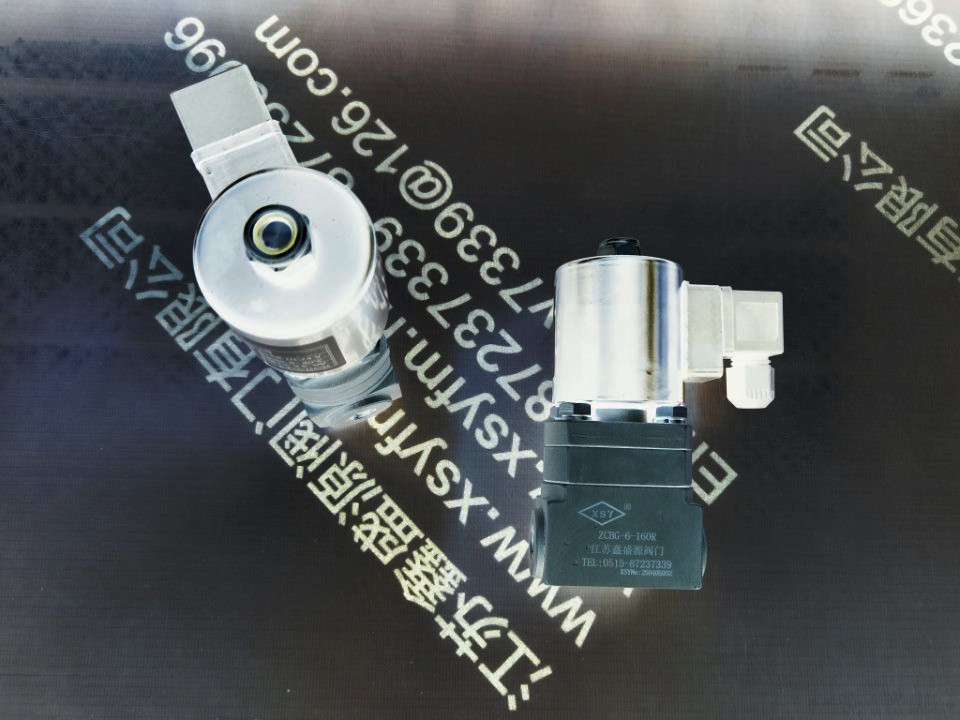

高压电磁阀产品介绍:

高压电磁阀作为自动化控制领域的关键元件,在众多复杂且严苛的工况中发挥着至关重要的作用。其性能和质量,使其成为各类高精度控制场景的理想选择。

高压电磁阀产品结构与特点:

(一)结构类型.高压电磁阀分为直动式和先导式两种结构原理。直动式结构简单,在一些小口径、对响应速度要求极高的场合表现出色,能迅速对电信号做出反应,实现阀门的开启与关闭。先导式则适用于较大口径及更高压力的环境,通过先导阀芯控制主阀的动作,利用介质压力差实现、稳定的运行。

(二)采用先导膜片式或活塞式结构,可承受高达 50 巴甚至更高的压力(部分特制产品压力可突破 300MPa)。整体设计紧凑,外观精美,占用空间小,便于在各类空间有限的设备中安装。运行时温升低,有效减少了因发热导致的性能衰减和安全隐患;并且运行过程安静无噪音,不会对工作环境造成干扰。通过三维密封结构,搭配多种可选择的密封材质,实现了阀门的零泄漏效果,确保介质传输的安全性和稳定性。动作响应速度极快,频率高,能够在短时间内多次开启和关闭,满足复杂控制逻辑下对阀门快速动作的需求,可在长时间、高频率的工作状态下稳定运行,减少维护频次。

高压电磁阀工作原理:

(一)常闭状态:当线圈通电时,产生的电磁力吸引先导阀芯打开先导孔,阀上腔内的压力迅速释放。此时,主阀活塞在介质压力的推动下,克服弹簧力等阻力,向上移动打开主阀口,介质开始流通。当线圈断电时,先导阀芯在弹簧的作用下复位,关闭先导孔。阀上腔内部压力因介质无法排出而逐渐升高,在压力差和弹簧力的共同作用下,主阀活塞向下移动,关闭主阀口,介质截止。

(二)常开状态:与常闭状态相反,当线圈通电时,电磁力使先导阀芯动作关闭先导孔,阀上腔内部压力逐渐升高。同时,复位弹簧推动主阀活塞向下移动,关闭主阀口,介质停止流通。当线圈断电时,先导阀芯依靠弹簧复位,先导孔打开,阀上腔内的压力得以释放。主阀活塞在介质压力的推动下向上移动,打开主阀口,介质恢复流通。

高压电磁阀技术规格:

(一)材质:阀体材质:提供黄铜和不锈钢两种选择。黄铜材质具有较好的导电性、导热性和耐腐蚀性,适用于一些对压力要求相对较低、介质腐蚀性较弱的场合,如低压水、气、油管路等。不锈钢材质(如 304、316、316L 等)则具有更强的耐腐蚀性,能在强酸、强碱、高温高压以及含有腐蚀性介质的恶劣环境中稳定工作,广泛应用于化工、石化、核工业等领域。

(二)适用介质:适用于水、气、油、蒸汽、燃气以及各种腐蚀性流体等几乎所有常见介质。无论是清洁的液体和气体,还是含有杂质、腐蚀性成分的特殊介质,高压电磁阀都能控制其流动。

(三)温度范围:能够在 - 100 至 + 200 摄氏度的宽泛温度范围内稳定工作。特殊定制的产品甚至可适应更极端的温度环境,从低温的液态气体输送到高温的蒸汽管路,都能确保阀门的正常运行和密封性能。

(四)粘度范围:对于介质的粘度,一般要求不超过 50C St。若介质粘度超过此值,可根据实际情况进行特别定制,通过优化内部结构和密封材料,确保阀门在高粘度介质中也能顺利开启和关闭,实现精准控制。

(五)防护性能:具备防水、防爆(Exd IICT5)、防腐蚀等多重防护功能。防水设计可有效防止水分进入电磁阀内部,避免因短路等问题影响阀门的正常工作,适用于潮湿环境或可能接触到水的场合。防爆功能使其能够在易燃易爆的危险环境中安全运行,如石化厂、炼油厂等存在可燃气体或粉尘的区域。防腐蚀特性则电磁阀在恶劣的化学环境中不会被腐蚀损坏,延长使用寿命。

(六)接线方式:提供接线座式、引线式和插头式三种接线方式,满足不同用户和安装场景的需求。接线座式便于接线和维护,适合在控制柜等需要集中布线的场合使用;引线式则更加灵活,可根据实际安装位置自由布线;插头式连接方便快捷,可实现快速插拔,便于设备的调试和更换。

(七)控制方式:支持常开和常闭两种基本控制模式,同时还可根据客户需求定制自保持等特殊控制方式。常开模式下,阀门在断电时保持开启状态,通电时关闭;常闭模式则相反,断电时关闭,通电时开启。自保持式电磁阀在动作后能够保持当前状态,无需持续通电,可有效节省能源并提高系统的稳定性。

(八)电源电压:支持直流 12 至 127 伏特,交流 36 至 380 伏特的宽泛电源电压范围,可适应不同地区、不同设备的电源要求。用户可根据实际使用环境和控制系统的电源规格,选择合适的电压等级,确保电磁阀与整个系统的兼容性。

(九)连接方式:可通过内螺纹、法兰等常见方式进行连接,也可根据实际需求定制其他类型的连接方式,如卡套式、焊接式等。内螺纹连接适用于小口径阀门,安装方便,密封性较好;法兰连接则适用于大口径、高压场合,连接牢固。定制的连接方式可满足一些特殊设备或管路的安装要求,确保阀门与系统的匹配。

(十)泄漏量:凭借密封技术和精密的制造工艺,高压电磁阀实现了零泄漏的性能。在各种工况下,都能确保介质不会从阀门的密封处泄漏,有效避免了介质的浪费和环境污染,同时保障了系统的安全稳定运行。

高压电磁阀应用领域:

1.航天与国防:在火箭发射、导弹系统、卫星设备等航天和国防领域,高压电磁阀用于控制推进剂、燃料、氧化剂等介质的流动。快速响应和零泄漏的特性,对于保障飞行器的安全发射、稳定飞行以及命中目标起着关键作用。例如,在火箭发动机的燃料供应系统中,高压电磁阀能够根据飞行控制指令,快速、准确地调节燃料流量,确保发动机在不同飞行阶段都能获得动力输出。

2.船舶重工:在船舶的动力系统、燃油系统、液压系统以及消防系统中广泛应用。在动力系统中,用于控制燃油的供应和切断,船舶发动机的稳定运行;在液压系统中,控制液压油的流向和压力,实现船舶各种机械设备的运作;在消防系统中,快速响应火灾报警信号,开启或关闭水、泡沫等灭火介质的输送管路,为船舶的消防安全提供保障。

3.核工业:在核电站的核反应堆冷却系统、放射性介质输送系统等关键环节发挥着重要作用。由于核工业对安全性要求极高,高压电磁阀必须具备出色的耐辐射性能、密封性能和长期稳定运行能力。它能够在高温、高压、强辐射的恶劣环境下,控制冷却剂、放射性介质等的流动,确保核反应堆的正常运行和安全防护。

4.石化与化工:石化和化工行业的生产过程涉及到各种高温、高压、易燃易爆、强腐蚀性的介质,高压电磁阀是实现自动化控制的核心部件之一。在石油炼制、化工合成、天然气输送等工艺流程中,用于控制原料、中间产品和成品的输送,以及反应釜、塔器等设备的压力调节和流量控制。例如,在乙烯生产装置中,高压电磁阀可根据反应温度、压力等参数,及时调节原料的进料量和反应产物的排出量,生产过程、稳定和安全。

5.电力:在火力发电、水力发电、风力发电等电力生产领域,高压电磁阀用于控制蒸汽、水、油等介质的流动,实现发电机组的启停、负荷调节以及设备的保护。在火力发电厂的汽轮机控制系统中,高压电磁阀能够快速响应控制信号,调节蒸汽的进汽量,从而控制汽轮机的转速和输出功率;在水电站的水轮机调速系统中,控制导叶的开度,实现对水流量的调节,水轮机的稳定运行和电能质量。

6.轻工与机械:在食品饮料、制药、包装、纺织等轻工业以及各类机械设备制造中,高压电磁阀用于自动化生产线的流体控制。在食品饮料生产过程中,用于控制水、糖浆、碳酸气等原料的输送和混合比例;在制药行业,确保药品生产过程中各种液体原料的计量和输送,满足药品质量控制的严格要求;在包装机械中,控制包装材料的输送和封口过程中的气体或液体介质的流动;在纺织机械中,调节印染、整理等工艺过程中的化学药剂和水的流量。

7.科研:在各类科研实验设备中,高压电磁阀用于控制实验介质的流动和压力,为科研人员提供稳定的实验条件。例如,在材料科学研究中,用于控制高温高压反应釜内的气体或液体介质的注入和排出,研究材料在不同条件下的性能变化;在生物医学实验中,控制培养液、试剂等液体的输送,为细胞培养、药物研发等实验提供精准的环境控制。

8.工业窑炉与干燥设备:在工业窑炉的燃烧控制系统中,高压电磁阀控制燃气或燃油的供应,根据窑炉的温度、压力等参数,及时调节燃料流量,窑炉的燃烧和稳定运行。在干燥设备中,用于控制热风、蒸汽等干燥介质的进出,实现对物料干燥过程的控制,提高干燥效率和产品质量。

9.给排水与消防:在城市给排水系统中,高压电磁阀用于控制水泵的启停、水塔的水位调节以及供水管网的压力控制,保障城市供水的安全和稳定。在消防系统中,作为消防水系统、泡沫灭火系统等的关键控制元件,在火灾发生时,迅速响应火灾报警信号,开启消防水源,将灭火介质输送到火灾现场,为灭火救援工作提供有力支持。

10.食品与清洗设备:在食品加工设备领域,高压电磁阀要求具备极高的卫生标准。在食品加工设备中,用于控制食品原料、清洗剂、消毒剂等的输送,确保食品生产过程的卫生安全;在食品设备中,如血液透析设备、高压氧舱等,控制液体和气体的流量和压力,为患者提供安全、有效的保障。在清洗设备中,高压电磁阀控制清洗液、高压水等的喷射和循环,实现对设备、零部件等清洗。

11.喷泉与景观:在城市景观喷泉、音乐喷泉等项目中,高压电磁阀通过控制水流的大小、方向和喷射时间,配合灯光和音乐效果,营造出绚丽多彩、富有动感的喷泉景观。其快速响应和稳定控制的特点,能够实现喷泉表演的多样化和高观赏性。

12.管道介质自动化控制:在各类工业管道和城市公用管道系统中,高压电磁阀作为自动化控制的执行元件,与传感器、控制器等组成完整的自动化控制系统。通过实时监测管道内介质的压力、流量、温度等参数,根据预设的控制策略,自动调节阀门的开度,实现管道介质、安全输送和精准控制。

高压电磁阀安装注意事项:

1.安装前务必仔细阅读产品说明书,全面了解产品的性能参数、工作原理和安装要求,确保产品符合实际使用需求。

2.对即将连接的管路进行彻底清洗,清除管路内的杂质、污垢和铁锈等,防止这些杂质进入电磁阀内部,影响阀门的正常动作和密封性能。若介质不洁净,必须在电磁阀前端安装合适精度的过滤器,定期对过滤器进行清洗和维护,确保其过滤效果。

3.对于长期未使用的电磁阀,在重新启用前,应先清除内部可能积聚的冷凝水、杂质等,可采用压缩空气吹扫或拆卸清洗等方式。在拆卸和清洗过程中,要注意记录各个部件的安装顺序,避免重新组装时出现错误。

4.高压电磁阀一般为单向工作阀门,安装时必须严格按照阀体上标注的箭头方向与管道中流体的实际流动方向一致,否则将导致阀门无法正常工作,甚至损坏阀门。

5.若电磁阀安装在可能出现结冰的环境中,在重新投入使用前,应对电磁阀进行适当的加热处理,如采用电伴热、蒸汽加热等方式,或者采取保温措施,防止阀门内部的介质结冰,损坏阀门。

l 6.建议在安装时尽量使阀体保持水平位置,线圈朝上。这种安装方式有助于延长电磁阀的使用寿命,确保阀门内部的部件能够正常运动和润滑。虽然部分型号的电磁阀可以允许任意安装,但在条件允许的情况下,遵循此安装姿势可获得更好的使用效果。

7.当电磁线圈的引出线(连接器)连接完毕后,要仔细检查连接是否牢固,确保接触较好。避免因连接松动导致接触不良,引起电磁阀无法正常工作或工作不稳定。对于需要持续生产的场合,为了在电磁阀出现故障时不影响生产,建议在电磁阀附近设置旁路管道和阀门,以便在维修电磁阀时,可通过旁路维持系统的正常运行。

As a key component in the field of automated control, high-pressure solenoid valves play a crucial role in numerous complex demanding working conditions. Their superior performance reliable quality make them an ideal choice for various high-precision control scenarios.

High-pressure solenoid valves are categorized into two structural principles: direct-acting pilot-operated. The direct-acting type features a simple structure excels in applications with small diameters extremely high requirements for response speed. It can quickly react to electrical signals to open close the valve. The pilot-operated type is suitable for environments with larger diameters higher pressures. It controls the action of the main valve through the pilot valve core, achieving efficient stable operation by utilizing the pressure difference of the medium.

Adopting a pilot diaphragm piston structure, these valves can withstand pressures of up to 50 bar even higher (some special products can withstand pressures exceeding 300MPa). With a compact design an elegant appearance, they occupy minimal space, facilitating installation in various equipment with limited space. During operation, the temperature rise is low, effectively reducing performance degradation potential safety hazards caused by heat generation. Additionally, their operation is quiet noiseless, ensuring no interference with the working environment. Thanks to the advanced three-dimensional sealing structure a variety of selectable sealing materials, these valves achieve zero leakage, ensuring the safety stability of medium transmission. They offer extremely fast response speeds high action frequencies, enabling multiple openings closings in a short time to meet the requirements of rapid valve actions in complex control logics. With high reliability, they can operate stably under long-term high-frequency working conditions, reducing maintenance frequency.

When the coil is energized, the generated electromagnetic force attracts the pilot valve core to open the pilot hole, rapidly releasing the pressure in the upper valve chamber. At this time, the main valve piston moves upward under the push of the medium pressure, overcoming resistance such as spring force, opens the main valve port, allowing the medium to flow. When the coil is de-energized, the pilot valve core resets under the action of the spring closes the pilot hole. The internal pressure of the upper valve chamber gradually increases as the medium cannot be discharged. Under the combined action of the pressure difference spring force, the main valve piston moves downward to close the main valve port, stopping the medium flow.

Contrary to the normally closed state, when the coil is energized, the electromagnetic force causes the pilot valve core to close the pilot hole, gradually increasing the internal pressure of the upper valve chamber. Meanwhile, the reset spring pushes the main valve piston downward to close the main valve port, halting the medium flow. When the coil is de-energized, the pilot valve core resets under the action of the spring, opening the pilot hole releasing the pressure in the upper valve chamber. The main valve piston moves upward under the push of the medium pressure, reopening the main valve port resuming the medium flow.

Valve Body Materials: Two options are available: brass stainless steel. Brass has good electrical conductivity, thermal conductivity, corrosion resistance, making it suitable for applications with relatively low pressure requirements weak corrosive media, such as low-pressure water, gas, oil pipelines. Stainless steel materials (such as 304, 316, 316L, etc.) have stronger corrosion resistance can operate stably in harsh environments with strong acids, alkalis, high temperatures, high pressures, corrosive media. They are widely used in the chemical, petrochemical, nuclear industries.

These valves are suitable for almost all common media, including water, gas, oil, steam, combustible gas, various corrosive fluids. Whether dealing with clean liquids gases special media containing impurities corrosive components, high-pressure solenoid valves can reliably control their flow.

They can operate stably within a wide temperature range -100°C to +200°C. Special customized products can even adapt to more extreme temperature environments, ensuring normal operation sealing performance in scenarios ranging low-temperature liquid gas transportation to high-temperature steam pipelines.

Generally, the viscosity of the medium should exceed 50 C St. If the medium viscosity exceeds this value, special customization can be carried out according to actual conditions. By optimizing the internal structure sealing materials, these valves can smoothly open close achieve precise control even with high-viscosity media.

These valves are equipped with multiple protection functions, including water resistance, explosion protection (Exd IICT5), corrosion resistance. The water-resistant design effectively prevents moisture entering the solenoid valve, avoiding malfunctions such as short circuits that could affect the normal operation of the valve. This makes them suitable for humid environments applications they may come into contact with water. The explosion protection function enables them to operate safely in flammable explosive hazardous environments, such as petrochemical plants refineries flammable gases dust may be present. The corrosion-resistant feature ensures that the solenoid valves are damaged by corrosion in harsh chemical environments, extending their service life.

Three wiring methods are provided: terminal block type, lead wire type, plug type, meeting the needs of different users installation scenarios. The terminal block type is convenient for wiring maintenance is suitable for centralized wiring in control cabinets other places. The lead wire type offers greater flexibility, allowing for free wiring according to the actual installation location. The plug type provides convenient quick connections, enabling fast plugging unplugging, which is convenient for equipment debugging replacement.

They support two basic control modes, normally open normally closed, can also be customized with special control modes such as self-holding according to customer requirements. In the normally open mode, the valve remains open when de-energized closes when energized. In the normally closed mode, the opposite occurs. The self-holding solenoid valve can maintain its current state after actuation without the need for continuous power supply, effectively saving energy enhancing system stability.

They support a wide range of power supply voltages, 12 to 127 volts for direct current 36 to 380 volts for alternating current, adapting to the power requirements of different regions equipment. Users can the appropriate voltage level according to the actual operating environment the power specifications of the control system to ensure the compatibility of the solenoid valve with the entire system.

Common connection methods such as internal thread flange are available, other connection methods can also be customized according to actual needs, such as ferrule type welding type. The internal thread connection is suitable for small-diameter valves, featuring easy installation good sealing performance. The flange connection is suitable for large-diameter high-pressure applications, providing a firm connection reliable sealing. Customized connection methods can meet the installation requirements of special equipment pipelines, ensuring a perfect match between the valve the system.

Thanks to advanced sealing technology precise manufacturing processes, high-pressure solenoid valves achieve excellent zero-leakage performance. Under various working conditions, they ensure that no medium leaks the valve seals, effectively preventing medium waste environmental pollution while guaranteeing the safe stable operation of the system.

Aerospace Defense Industry: In aerospace defense applications, such as rocket launches, missile systems, satellite equipment, high-pressure solenoid valves are used to precisely control the flow of propellants, fuels, oxidizers, other media. Their high reliability, fast response, zero-leakage characteristics are crucial for ensuring the safe launch, stable flight, accurate target hitting of aircraft. For example, in the fuel supply system of a rocket engine, high-pressure solenoid valves can quickly accurately adjust the fuel flow according to flight control commands, ensuring that the engine obtains optimal power output at different flight stages.

Shipbuilding Industry: Widely used in the power system, fuel system, hydraulic system, fire protection system of ships. In the power system, they control the supply cut-off of fuel to ensure the stable operation of ship engines. In the hydraulic system, they precisely control the flow direction pressure of hydraulic oil to achieve the efficient operation of various ship mechanical equipment. In the fire protection system, they quickly respond to fire alarm signals, opening closing the pipelines for conveying water, foam, other fire-fighting media, providing reliable protection for ship fire safety.

Nuclear Industry: Playing a vital role in key components of nuclear power plants, such as nuclear reactor cooling systems radioactive medium transportation systems. Due to the extremely high requirements for safety reliability in the nuclear industry, high-pressure solenoid valves must possess excellent radiation resistance, sealing performance, long-term stable operation capabilities. They can precisely control the flow of coolants, radioactive media, etc., in harsh environments with high temperatures, high pressures, strong radiation, ensuring the normal operation safety protection of nuclear reactors.

Petrochemical Chemical Industry: The production processes in the petrochemical chemical industries involve various high-temperature, high-pressure, flammable, explosive, highly corrosive media. High-pressure solenoid valves are one of the core components for achieving automated control. In processes such as petroleum refining, chemical synthesis, natural gas transportation, they control the transportation of raw materials, intermediate products, finished products, as well as the pressure regulation flow control of reactors, towers, other equipment. For example, in an ethylene production unit, high-pressure solenoid valves can adjust the feed rate of raw materials the discharge rate of reaction products in a timely manner according to reaction temperature, pressure, other parameters, ensuring the efficient, stable, safe production process.

Power Industry: In the fields of thermal power generation, hydropower generation, wind power generation, high-pressure solenoid valves are used to control the flow of steam, water, oil, other media, realizing the start-stop, load regulation, equipment protection of generator sets. In the steam turbine control system of a thermal power plant, high-pressure solenoid valves can quickly respond to control signals adjust the steam inlet flow, thereby controlling the rotational speed output power of the steam turbine. In the water turbine speed regulation system of a hydropower station, they precisely control the opening degree of the guide vanes to regulate the water flow, ensuring the stable operation of the water turbine the quality of electrical energy.

Light Industry Machinery: In the light industry, including food beverage, pharmaceuticals, packaging, textiles, various mechanical equipment manufacturing, high-pressure solenoid valves are used for fluid control in automated production lines. In the food beverage production process, they control the transportation mixing ratio of raw materials such as water, syrup, carbonated gas. In the pharmaceutical industry, they ensure the accurate metering transportation of various liquid raw materials during the drug production process to meet the strict requirements of drug quality control. In packaging machinery, they control the transportation of packaging materials the flow of gas liquid media during the sealing process. In textile machinery, they adjust the flow of chemical agents water in processes such as dyeing finishing.

Scientific Research: In various scientific research experimental equipment, high-pressure solenoid valves are used to precisely control the flow pressure of experimental media, providing stable reliable experimental conditions for researchers. For example, in materials science research, they control the injection discharge of gas liquid media in high-temperature high-pressure reactors to study the performance changes of materials under different conditions. In biomedical experiments, they precisely control the transportation of culture media, reagents, other liquids, providing accurate environmental control for cell culture, drug research development, other experiments.

Industrial Furnaces Drying Equipment: In the combustion control system of industrial furnaces, high-pressure solenoid valves control the supply of gas fuel. According to parameters such as furnace temperature pressure, they timely adjust the fuel flow to ensure the efficient combustion stable operation of the furnace. In drying equipment, they control the intake exhaust of hot air, steam, other drying media, achieving precise control of the material drying process improving drying efficiency product quality.

Water Supply Drainage Fire Protection: In urban water supply drainage systems, high-pressure solenoid valves control the start-stop of water pumps, the regulation of water tower water levels, the pressure control of water supply networks, ensuring the safe stable supply of urban water. In the fire protection system, as key control components of fire water systems, foam fire extinguishing systems, etc., they quickly respond to fire alarm signals in the event of a fire, opening the fire water source transporting fire-fighting media to the fire site, providing strong support for fire-fighting rescue work.

Food, Medical, Cleaning Equipment: In the fields of food processing medical equipment, high-pressure solenoid valves are required to meet extremely high hygiene standards reliability. In food processing equipment, they control the transportation of food raw materials, cleaning agents, disinfectants, etc., ensuring the hygiene safety of the food production process. In medical equipment, such as hemodialysis equipment hyperbaric oxygen chambers, they precisely control the flow pressure of liquids gases, providing safe effective guarantees for patient treatment. In cleaning equipment, high-pressure solenoid valves control the spraying circulation of cleaning liquids high-pressure water, achieving efficient cleaning of equipment, components, etc.

Fountains Landscapes: In urban landscape fountains, musical fountains, other projects, high-pressure solenoid valves precisely control the size, direction, spraying time of water flow. Combined with lighting music effects, they create colorful dynamic fountain landscapes. Their fast response stable control characteristics enable diverse highly ornamental fountain performances.

Automated Control of Pipeline Media: In various industrial pipelines urban public pipeline systems, high-pressure solenoid valves, as the executive components of automated control, form a complete automated control system together with sensors, controllers, etc. By real-time monitoring of parameters such as pressure, flow, temperature of the media in the pipeline, according to preset control strategies, they automatically adjust the valve opening degree to achieve efficient, safe transportation, precise control of pipeline media.

Before installation, carefully read the product instruction manual to fully understand the product's performance parameters, working principles, installation requirements, ensuring that the product meets the actual usage needs.

Thoroughly clean the pipeline to be connected, removing impurities, dirt, rust, etc. inside the pipeline to prevent these impurities entering the solenoid valve affecting the normal operation sealing performance of the valve. If the medium is clean, install a filter with an appropriate precision at the front end of the solenoid valve, regularly clean maintain the filter to ensure its filtering effect.

For solenoid valves that have been used for a long time, before reactivation, remove any accumulated condensate, impurities, etc. inside. This can be done by blowing with compressed air disassembling cleaning. When disassembling cleaning, pay attention to recording the installation order of each component to avoid errors during reassembly.

High-pressure solenoid valves are generally one-way working valves. During installation, strictly ensure that the arrow direction marked on the valve body is consistent with the actual flow direction of the fluid in the pipeline. Otherwise, the valve will operate normally may even be damaged.

If the solenoid valve is installed in an environment icing may occur, before putting it back into use, appropriately heat the solenoid valve, such as by using electric tracing, steam heating, etc., take reliable insulation measures to prevent the medium inside the valve freezing damaging the valve.

It is recommended to keep the valve body in a horizontal position with the coil facing upward during installation. This installation method helps to extend the service life of the solenoid valve ensures the normal movement lubrication of the internal components of the valve. Although some valve models allow arbitrary installation, following this installation posture can achieve better usage results when conditions permit.

After connecting the lead wires (connectors) of the electromagnetic coil, carefully check whether the connection is firm to ensure good contact. Avoid poor contact caused by loose connections, which may lead to abnormal operation unstable performance of the solenoid valve. For applications that require continuous production, to avoid affecting production in case of solenoid valve failure, it is recommended to set up bypass pipelines valves near the solenoid valve. This allows the system to continue operating through the bypass during solenoid valve maintenance.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!