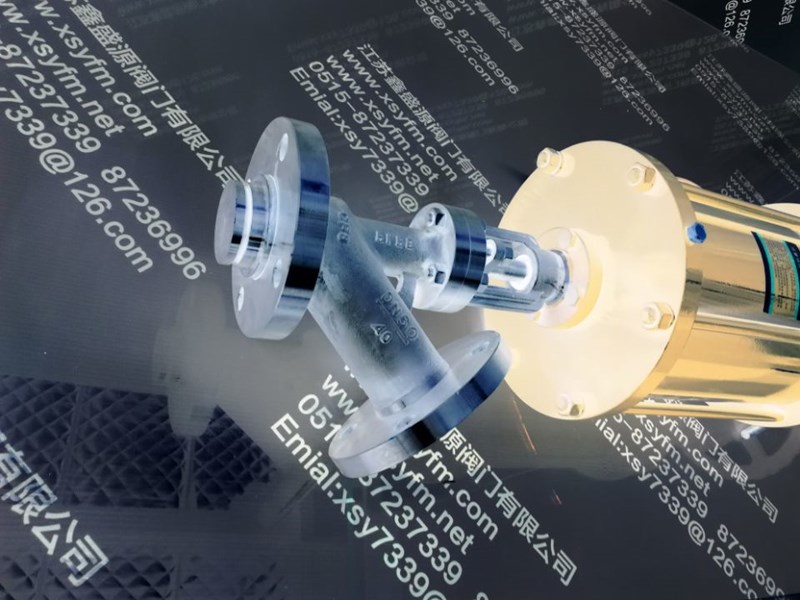

气动放料阀

气动放料阀是一种通过气动执行器控制阀门启闭的装置,广泛应用于化工、石化、石油、制药、食品加工、造纸、采矿、电力、市政等领域的反应釜、储罐和其他容器的底部排料、放料、取样和无死区关断操作。阀门借助底部法兰焊接于容器底部,可有效消除介质残留。根据结构不同,气动放料阀可分为上展式、下展式和柱塞式三种类型,具有操作方便、启闭灵活、密封性能稳定、耐腐蚀、耐冲刷、维修简便等特点4。

气动放料阀主要性能参数

适用介质:水、丙酮、酒精、氨、碳酸钡、苯(WCB材质,-29℃~425℃);颗粒、油品、纸浆、二氧化碳(不锈钢材质,-60℃~232℃)

严禁使用介质:含氟离子液体(如HF)、强碱及磷酸(温度>150℃,浓度>30%)

气动放料阀工作温度:不锈钢材质一般≤150℃,特殊情况下-5℃~225℃

压力范围:0.6~2.5MPa

通径范围:DN25~DN250

连接方式:法兰连接

安装方式:一般应水平安装13

气动放料阀工作原理

气动放料阀通过气源驱动活塞运动,带动阀杆实现阀门的开启和关闭。气源进入气缸上部时关闭阀门,进入下部时开启阀门,可实现远程自动控制,提高操作安全性5。

气动放料阀Product Overview

Pneumatic discharge valves are devices that use pneumatic actuators to control the opening closing of valves. They are widely used in the bottom discharge, sampling, dead-end shut-off operations of reactors, storage tanks, other containers in industries such as chemical, petrochemical, petroleum, pharmaceutical, food processing, papermaking, mining, power, municipal engineering. The valve is welded to the bottom of the container via a flange, effectively eliminating medium residue. According to structural differences, pneumatic discharge valves can be divided into three types: top-lift, bottom-lift, plunger types. They feature convenient operation, flexible opening closing, reliable sealing, corrosion resistance, erosion resistance, easy maintenance.4

Main Performance Parameters

Applicable Media: Water, acetone, alcohol, ammonia, barium carbonate, benzene (WCB material, -29℃~425℃); particles, oil, pulp, carbon dioxide (stainless steel material, -60℃~232℃)

Prohibited Media: Liquids containing fluoride ions (e.g., HF), strong alkalis, phosphoric acid (temperature >150℃, concentration >30%)

Working Temperature: Generally ≤150℃ for stainless steel, -5℃~225℃ under special conditions

Pressure Range: 0.6~2.5MPa

Nominal Diameter: DN25~DN250

Connection Type: Flange connection

Installation Method: Generally installed horizontally13

Working Principle

The pneumatic discharge valve uses air pressure to drive the piston, which moves the valve stem to open close the valve. When air enters the top of the cylinder, the valve closes; when air enters the bottom, the valve opens. This allows remote automatic control, improving operational safety.5

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!