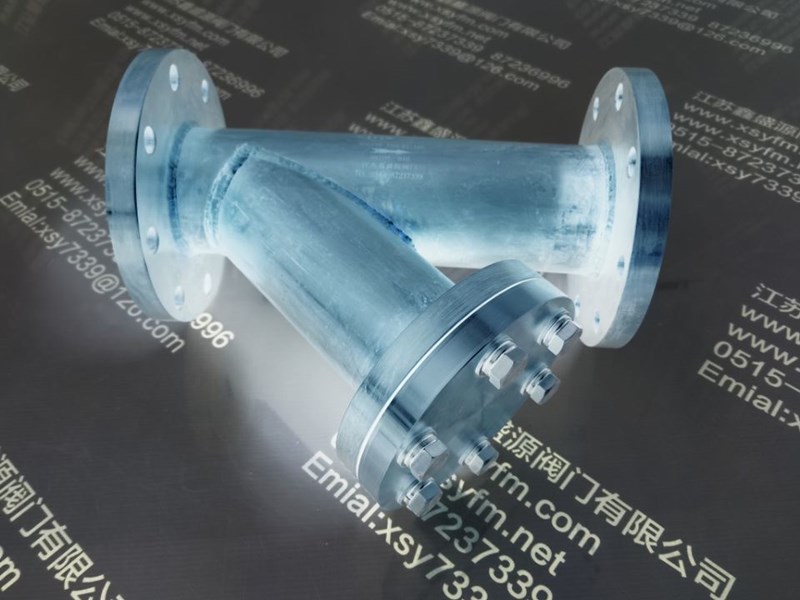

Y型焊接过滤器以确保所有设备管道上安置免受因管道内杂质、铁锈、焊屑等带来的堵塞和损坏,从而避免了维修费用和生产损失。1、Y型焊接过滤器适用于蒸汽、空气、水、油品等系统管道中,保护各种计量仪器、泵机、阀门、蔬水器等设备抗污性强,排污方便;流通面积大,压力损失小;结构简单,体积小。2、过滤网材质,有奥氏体304、316、316L。3、连接形式:螺纹,承插焊,法兰

Y型焊接过滤器以确保所有设备管道上安置免受因管道内杂质、铁锈、焊屑等带来的堵塞和损坏,从而避免了维修费用和生产损失。

1、Y型焊接过滤器适用于蒸汽、空气、水、油品等系统管道中,保护各种计量仪器、泵机、阀门、蔬水器等设备抗污性强,排污方便;流通面积大,压力损失小;结构简单,体积小。

2、过滤网材质,有奥氏体304、316、316L

3、连接形式:螺纹,承插焊

B10海水过滤器

B10海水过滤器是一种专为海洋及高腐蚀性环境(特别是海水介质)设计和制造的过滤设备。"B10" 通常指其核心部件滤网采用铜镍合金(CuNi) 材料,具体牌号一般为 CuNi 90/10(C70600),这是一种公认的海水专用耐腐蚀材料。该过滤器通过拦截海水中的杂质,保护船舶系统、海洋平台及其它海洋工程中的关键设备。

2. B10海水过滤器核心特点

耐腐蚀性: 主要过流部件(如滤网、阀体、阀盖)通常采用B10铜镍合金(CuNi 90/10)或其他耐海水材料(如铝青铜、双相不锈钢、奥氏体不锈钢等),能有效抵抗海水的氯离子腐蚀、冲刷腐蚀和电化学腐蚀。

防海生物附着: 铜镍合金表面不易附着海生物(如藤壶、藻类),减少了维护需求并确定了流通能力。

长寿命与高稳定性: 材料的选择和设计使其在恶劣的海洋环境中具有很长的使用寿命和极高的运行稳定性。

低维护成本: 耐腐蚀性降低了因腐蚀损坏而进行更换或维修的频率和成本。

3. B10海水过滤器材料选择

主要材料: B10铜镍合金(CuNi 90/10, UNS C70600) 是标准和高性价比的选择。

其他材料: 根据具体需求和预算,也可能采用:

铝青铜 (Aluminum Bronze)

双相不锈钢 (Duplex Stainless Steel, 如UNS S31803/S32205)

奥氏体不锈钢 (Super Austenitic Stainless Steel, 如254 SMO®)

钛 (Titanium) 用于要求极高的场合。

4. B10海水过滤器连接方式

可根据系统要求提供多种连接方式:

法兰连接 (Flanged Ends): 很常见,标准如ANSI B16.5, JIS, DIN等。

对焊连接 (Butt Weld Ends): 用于无泄漏的高压管道。

螺纹连接 (Screwed Ends): 用于小口径低压管路。

5.B10海水过滤器 工作原理

海水从过滤器进口进入,穿过内部由B10材料制成的滤网(篮式或网式)。滤网将海水中的悬浮颗粒、海洋生物、碎片等杂质截留积聚。洁净的海水则从出口流出,进入后续的泵、热交换器、喷嘴、阀门等设备,防止这些设备发生堵塞、磨损或腐蚀。

6. B10海水过滤器应用领域

专门用于处理海水介质的系统和平台:

船舶与舰艇: 海水冷却系统、消防系统、压载水系统、舱底水系统。

海上油气平台: 海水注入系统、冷却系统、消防水系统。

海水淡化厂: 预处理过滤,保护反渗透膜。

滨海电站: 循环水冷却系统。

海洋渔业及 aquaculture: 海水供水过滤。

B10 Seawater Strainer Product Overview

1. Product Definition

A B10 Seawater Strainer is a type of filtration equipment specifically designed manufactured for marine highly corrosive environments, particularly for seawater service. The designation "B10" typically indicates that its core component, the screen, is made copper-nickel (CuNi) alloy, specifically CuNi 90/10 (C70600), which is a recognized corrosion-resistant material for seawater applications. It protects critical equipment in ship systems, offshore platforms, other marine engineering applications by intercepting impurities in seawater.

2. Key Features

Excellent Corrosion Resistance: Primary wetted parts (e.g., screen, body, cover) are typically constructed B10 copper-nickel alloy (CuNi 90/10) other superior seawater-resistant materials (e.g., aluminum bronze, duplex stainless steel, super austenitic stainless steel), providing effective resistance against chloride ion corrosion, erosion, galvanic corrosion in seawater.

Anti-Fouling Properties: The copper-nickel alloy surface inhibits the attachment of marine organisms (such as barnacles, algae), reducing maintenance needs ensuring flow capacity.

Long Service Life & High Reliability: Material selection design ensure a long operational lifespan extreme reliability in harsh marine environments.

Low Maintenance Cost: Superior corrosion resistance significantly reduces the frequency cost of replacement repair due to corrosion damage.

3. Material Selection

Primary Material: B10 Copper-Nickel Alloy (CuNi 90/10, UNS C70600) is the standard cost-effective choice.

Alternative Materials: Depending on specific requirements budget, other materials may be used:

Aluminum Bronze

Duplex Stainless Steel (e.g., UNS S31803/S32205)

Super Austenitic Stainless Steel (e.g., 254 SMO®)

Titanium for the most demanding applications.

4. Connection Types

Available with various end connections to meet system requirements:

Flanged Ends: Most common, standards include ANSI B16.5, JIS, DIN, etc.

Butt Weld Ends: For permanent, leak-proof high-pressure piping.

Screwed Ends: For small-bore, low-pressure piping.

5. Working Principle

Seawater enters the strainer through the inlet passes through an internal screen (basket mesh) made of B10 material. The screen retains accumulates impurities such as suspended solids, marine organisms, debris. The cleaned seawater then exits through the outlet flows to downstream equipment like pumps, heat exchangers, spray nozzles, valves, preventing clogging, abrasion, corrosion in those components.

6. Applications

Specifically designed for systems platforms handling seawater:

Ships & Vessels: Seawater cooling systems, firefighting systems, ballast water systems, bilge systems.

Offshore Oil & Gas Platforms: Seawater injection systems, cooling systems, firewater systems.

Desalination Plants: Pre-filtration to protect reverse osmosis membranes.

Coastal Power Stations: Circulating water cooling systems.

Marine Fisheries & Aquaculture: Seawater intake filtration.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!