防爆电磁阀产品概述

防爆电磁阀是一种专为在存在易燃易爆气体、蒸汽或粉尘等危险环境中使用而设计的特殊阀门,是工业自动化控制系统中保障安全的关键执行元件,主要用于控制各类易燃易爆流体介质的通断、流量及压力。

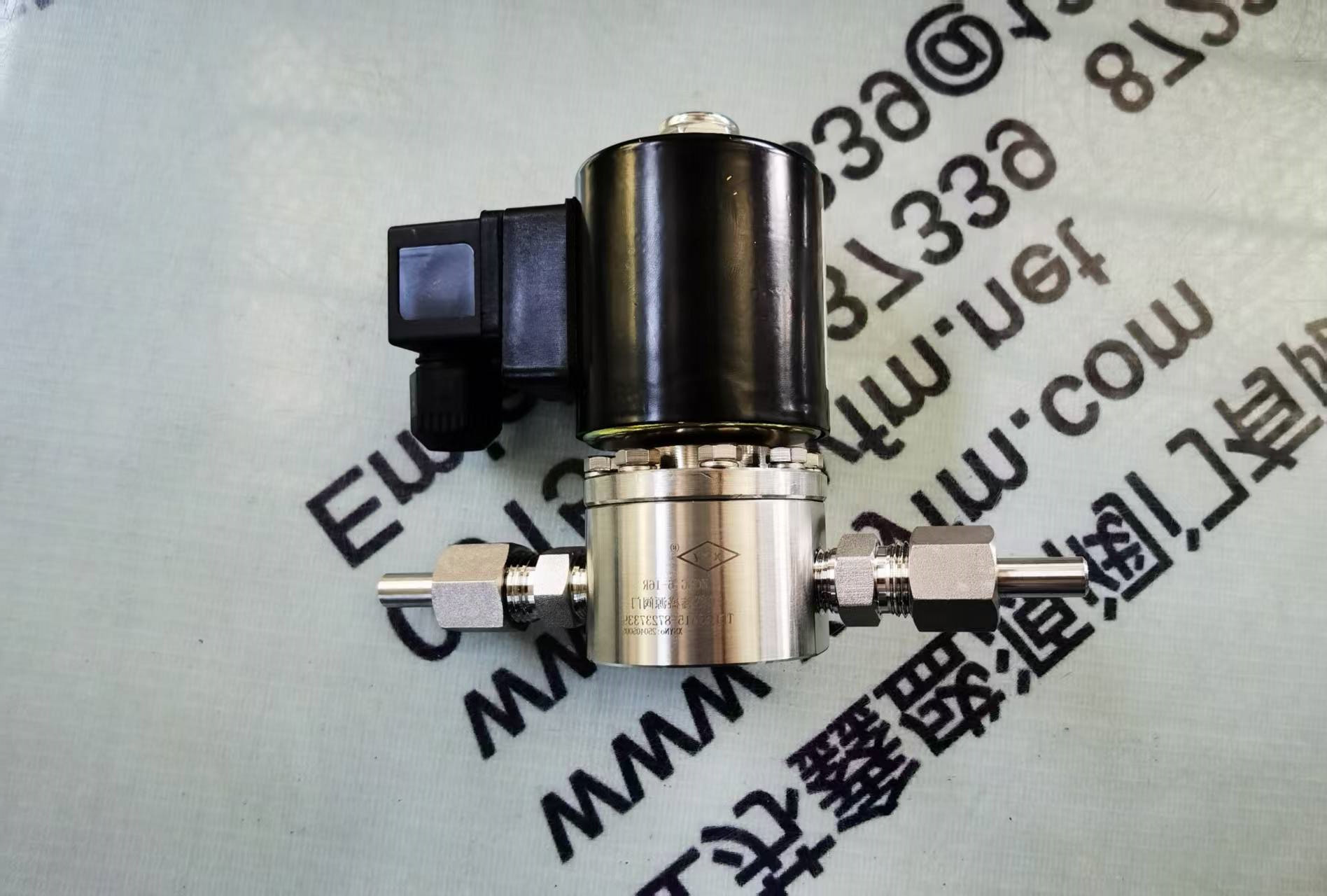

防爆电磁阀结构设计

1. 防爆外壳:采用高强度金属材料,如不锈钢、铸铝等一次拉伸成型,经过精密加工,防爆连接面涂防弧漆,严格按照国家防爆标准制造,能承受内部爆炸压力,阻止爆炸向外部传播。例如,隔爆型外壳的接合面间隙、长度等参数均符合GB 3836.2标准要求 ,确保外壳密封性和结构强度。

2. 密封结构:选用特殊密封材料,如氟橡胶、聚四氟乙烯等,具备良好的耐腐蚀性和抗老化性能,可有效防止可燃气体、粉尘等进入阀体内部,避免潜在爆炸危险。

3. 内部组件:阀芯与阀体配合精度极高,运动灵活顺畅,能快速响应控制信号,实现对流体控制;电磁线圈采用特殊工艺制造,绝缘性能和耐热性能良好,防止因线圈过热、短路等故障产生电火花。

防爆电磁阀工作原理

与普通电磁阀类似,防爆电磁阀基于电磁感应原理工作。当电磁线圈通电时,产生磁场,使铁芯产生吸力,带动阀芯克服弹簧力向上移动,压迫或释放弹簧,推动或放开密封件,开启通道,介质流通;断电时,磁场消失,弹簧力使阀芯复位,关闭通道,切断介质流动。不同之处在于,防爆电磁阀在设计和制造过程中采取诸多防爆措施,确保在危险环境中安全运行,避免成为点火源引发爆炸。

防爆电磁阀产品特点

1. 高安全性:满足严格防爆标准,如IECEx、ATEX、GB 3836等,能有效防止内部产生的电火花、高温等点燃外部易燃易爆气体,保障人员和设备安全。

2. 稳定性强:采用材料和制造工艺,结构坚固耐用,适应恶劣工作环境,如高温、高压、潮湿、腐蚀等,可长期稳定运行,减少维护成本和停机时间。

3. 响应迅速:阀芯设计合理,动作灵敏,能快速开启和关闭,响应时间短,满足工业自动化系统对快速控制的需求。

4. 适配性好:有多种规格和型号,可根据不同工作压力、温度、介质等条件选择合适产品;还可与各种自动化控制系统集成,实现远程监控和自动控制。

防爆电磁阀应用领域

1. 石油化工:用于原油开采、炼油、化工原料生产与加工等环节,如控制易燃易爆的石油、天然气、各类化工原料的输送。

2. 燃气行业:城市燃气输配系统、燃气加气站、燃气锅炉等设备中,实现对煤气、天然气、液化石油气等燃气的安全控制。

3. 矿山开采:煤矿、金属矿等开采作业中,用于控制瓦斯、粉尘等易燃易爆物质相关的通风、排水、输送等系统。

4. 制药行业:在生产易燃易爆化学药品的车间,控制相关原料和成品的输送与处理。

防爆电磁阀主要参数

1. 防爆等级:常见有Ex d ⅡB T4、Ex d ⅡC T6等,“Ex”表示防爆,“d”代表隔爆型,“ⅡB”“ⅡC”指适用爆炸性气体环境类别,“T4”“T6”表示允许表面温度组别 。

2. 公称压力:范围通常为0 - 100MPa,可满足不同压力要求的工况。

3. 公称通径:一般在DN1 - DN500之间,提供多种尺寸选择,满足不同流量需求。

4. 适用温度:依据阀体和密封材料不同,适用温度范围有所差异,如-200℃ - 650℃。

5. 阀体材质:包括黄铜、铸铁、铸钢、不锈钢304、316等,可根据介质腐蚀性和工作环境选择。

Overview of Explosion-Proof Solenoid Valves

Explosion-proof solenoid valves are special valves designed for use in hazardous environments flammable explosive gases, vapors, dust may exist. They are key actuators in industrial automation control systems, ensuring safety by precisely controlling the on-off, flow, pressure of various flammable explosive fluid media.

Structural Design

1. Explosion-Proof Enclosure: Made of high-strength metal materials such as stainless steel cast aluminum, formed by one-time stretching precision machining. The explosion-proof joint surfaces are coated with arc-resistant paint, manufactured in strict accordance with national explosion-proof standards. They can withstand internal explosion pressure prevent the spread of explosions to the outside. For example, the gap length of the joint surfaces of flameproof enclosures meet the requirements of GB 3836.2, ensuring enclosure tightness structural strength.

2. Sealing Structure: Uses special sealing materials such as fluororubber PTFE, which have good corrosion resistance anti-aging properties. They effectively prevent flammable gases, dust, etc., entering the valve body, avoiding potential explosion hazards.

3. Internal Components: The valve core valve body have extremely high fitting precision, ensuring flexible smooth movement, which can quickly respond to control signals for precise fluid control. The electromagnetic coil is manufactured using special processes, with good insulation heat resistance, preventing electric sparks caused by coil overheating, short circuits, other faults.

Working Principle

Similar to ordinary solenoid valves, explosion-proof solenoid valves operate based on electromagnetic induction. When the electromagnetic coil is energized, a magnetic field is generated, causing the iron core to produce suction. This drives the valve core to move upward against the spring force, compressing releasing the spring, pushing releasing the seal, opening the channel to allow medium flow. When de-energized, the magnetic field disappears, the spring force resets the valve core, closing the channel cutting off medium flow. The difference is that explosion-proof solenoid valves adopt multiple explosion-proof measures during design manufacturing to ensure safe operation in hazardous environments prevent them becoming ignition sources that could trigger explosions.

Product Features

1. High Safety: Meet strict explosion-proof standards such as IECEx, ATEX, GB 3836. They effectively prevent electric sparks, high temperatures, etc., generated internally igniting external flammable explosive gases, ensuring the safety of personnel equipment.

2. Strong Stability: Made of high-quality materials advanced manufacturing processes, they have a robust durable structure, adapting to harsh working environments such as high temperature, high pressure, humidity, corrosion. They can operate stably for a long time, reducing maintenance costs downtime.

3. Rapid Response: The valve core is reasonably designed, with sensitive action, enabling quick opening closing. The short response time meets the requirements of industrial automation systems for rapid control.

4. Good Adaptability: Available in various specifications models, which can be selected according to different working pressures, temperatures, media, other conditions. They can also be integrated with various automation control systems to realize remote monitoring automatic control.

Application Fields

1. Petrochemical Industry: Used in crude oil extraction, oil refining, chemical raw material production processing, such as controlling the transportation of flammable explosive petroleum, natural gas, various chemical raw materials.

2. Gas Industry: Applied in urban gas distribution systems, gas filling stations, gas boilers, other equipment to safely control gases such as coal gas, natural gas, liquefied petroleum gas.

3. Mining Industry: Used in coal mines, metal mines, other mining operations to control ventilation, drainage, transportation, other systems related to flammable explosive substances such as gas dust.

4. Pharmaceutical Industry: Used in workshops producing flammable explosive chemicals to control the transportation processing of related raw materials finished products.

Main Parameters

1. Explosion-Proof Rating: Common ratings include Ex d ⅡB T4, Ex d ⅡC T6, etc. "Ex" indicates explosion-proof, "d" represents flameproof type, "ⅡB" "ⅡC" refer to the categories of explosive gas environments, "T4" "T6" indicate the maximum allowable surface temperature classes.

2. Nominal Pressure: Usually ranges 0 to 100MPa, meeting the requirements of different pressure conditions.

3. Nominal Diameter: Generally between DN1 DN500, providing multiple size options to meet different flow requirements.

4. Operating Temperature: Depending on the valve body sealing materials, the applicable temperature range varies, such as -200℃ to 650℃.

5. Valve Body Material: Includes brass, cast iron, cast steel, stainless steel 304, 316, etc., which can be selected according to medium corrosiveness working enviro

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!