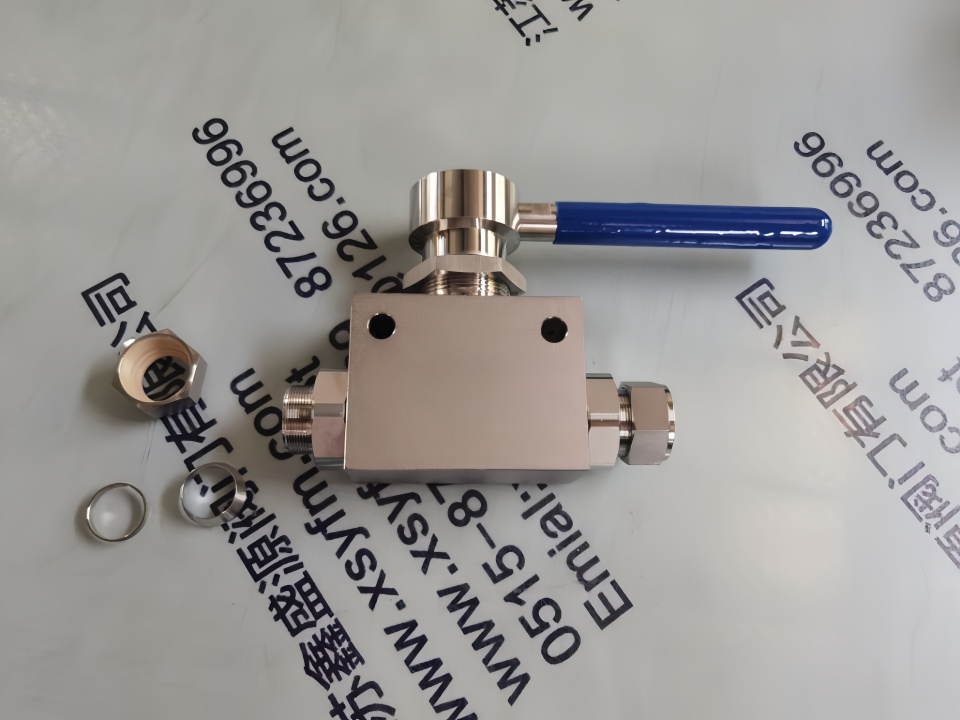

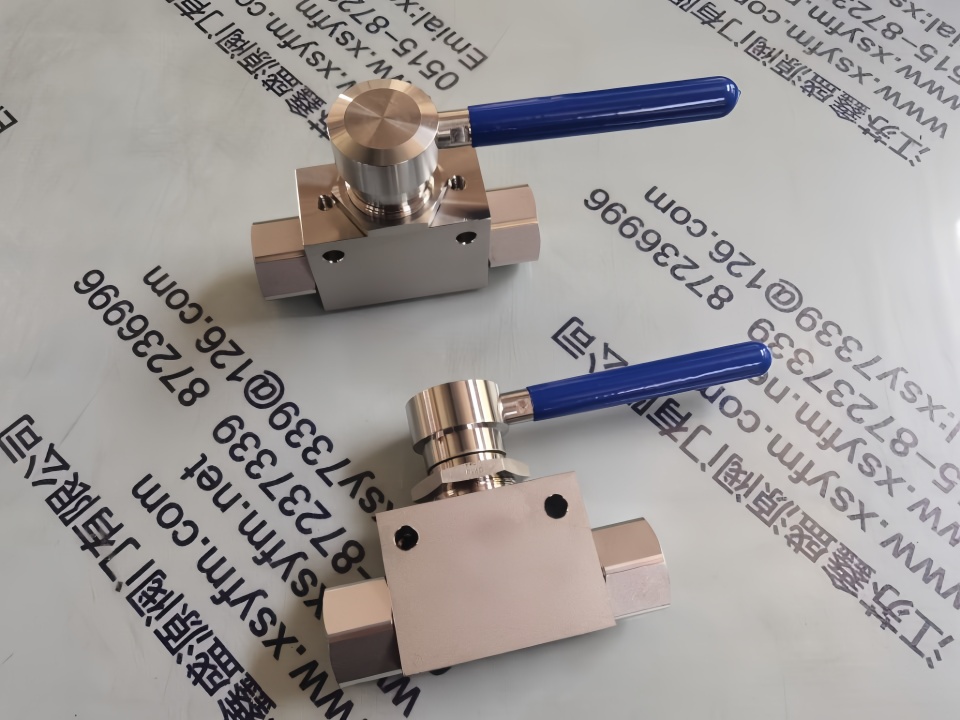

面板安装高压球阀产品概述

面板安装高压球阀是一类专为高压工况设计,且便于安装在各种设备面板上的球阀。其在结构、性能、应用等方面具有独特优势,是众多工业领域的关键流体控制部件。

面板安装高压球阀结构设计:通常采用整体锻造阀体,确保高强度与抗冲击性,能承受高压而不发生变形或破裂。阀杆与球体紧密连接,采用防吹出设计,防止高压下阀杆脱离,保障操作安全。阀座一般选用聚四氟乙烯(PTFE)或金属材料,前者密封性好、摩擦系数低,后者耐高温、耐磨损,适用于高温高压及特殊介质工况。球体加工精度极高,表面光滑,与阀座配合紧密,实现双向密封,有效减少流体泄漏。

面板安装高压球阀工作原理:通过旋转手柄带动阀杆,阀杆进而驱动球体旋转。当球体通孔与管道轴线一致时,阀门全开,流体顺畅通过;当球体旋转90度,通孔与管道垂直,阀门关闭,截断流体。操作简便,只需1/4圈即可完成全开或全关动作,可快速响应系统对流体的通断控制需求。

面板安装高压球阀产品特点:

1. 耐压性能:可承受高达数千psi甚至更高压力,适用于高压液压系统、石油天然气输送、高压试验设备等对压力要求严苛的场景。

2. 密 封:精密的球体与阀座配合的密封材料,阀门在高压下的良好密封性,减少泄漏风险,提高系统稳定性与安全性。

3. 操作便捷:轻巧的手柄设计,操作扭矩小,即使在高压状态下也能轻松实现阀门的开闭,可手动操作,也便于集成自动化控制。

4. 安装简便:面板安装方式,只需在设备面板上开孔,通过配套的安装螺母或螺栓即可固定,节省空间,便于集中控制与维护。

5. 寿命长久:材料与精密制造工艺,使其具备良好的耐磨性与抗腐蚀性,能在恶劣环境下长期稳定运行,降低维护成本与更换频率。

面板安装高压球阀应用领域:

1. 石油与天然气:在开采、输送和加工环节,用于高压气体、液体的截断与控制,如井口装置、输气管道、炼油厂等。

2. 化工行业:适用于各种腐蚀性、易燃易爆介质的管路控制,如反应釜进料出料、高压合成工艺等。

3. 液压系统:广泛应用于工程机械、冶金设备、航空航天等领域的液压系统,控制油液的流通与截止,保障设备正常运行。

4. 能源电力:用于核电站、火力发电厂的冷却系统、蒸汽管路等,确保高压介质的安全输送与控制。

5. 科研与测试:高压试验设备、实验室仪器中,用于控制高压流体,满足实验与测试需求。

面板安装高压球阀主要参数:

1. 公称压力:常见范围为10MPa - 100MPa(1450psi - 14500psi),也有更高压力等级产品,满足不同高压工况。

2. 公称通径:一般从DN6(1/4英寸)到DN100(4英寸)不等 ,可根据流量需求选择合适规格。

3. 适用温度:取决于阀体与密封材料,PTFE密封一般适用于-20℃ - 200℃,金属密封可承受更高温度,达500℃甚至更高。

4. 阀体材质:多采用不锈钢(如304、316)、合金钢,以强度与耐腐蚀性;特殊工况可选用哈氏合金、蒙乃尔合金等。

5. 连接方式:除面板安装外,进出口端常见螺纹连接(如NPT、BSPT)、焊接连接(对焊、承插焊),便于与管道系统连接。

Overview of Panel Mounted High - Pressure Ball Valve Products

Panel mounted high - pressure ball valves are a type of ball valves specifically designed for high - pressure working conditions are easy to install on the panels of various devices. They have unique advantages in terms of structure, performance, application, are key fluid control components in many industrial fields.

Structural Design:The valve body is usually forged integrally to ensure high strength impact resistance, can withstand high pressure without deformation rupture. The valve stem is closely connected to the ball adopts an anti - blowout design to prevent the valve stem disengaging under high pressure ensure operation safety. The valve seat generally uses polytetrafluoroethylene (PTFE) metal materials. The former has good sealing performance a low friction coefficient, while the latter is resistant to high temperatures wear, is suitable for high - temperature, high - pressure, special medium working conditions. The ball is processed with extremely high precision, has a smooth surface, closely cooperates with the valve seat to achieve double - sided sealing, effectively reducing fluid leakage.

Working Principle:The handle is rotated to drive the valve stem, the valve stem then drives the ball to rotate. When the through - hole of the ball is in line with the axis of the pipeline, the valve is fully open, the fluid can pass smoothly; when the ball rotates 90 degrees the through - hole is perpendicular to the pipeline, the valve is closed, cutting off the fluid. The operation is simple, a full - open full - closed action can be completed with just a 1/4 - turn, which can quickly respond to the system's on - off control requirements for the fluid.

Product Features:

1. Excellent Pressure Resistance:It can withstand pressures as high as several thousand psi even higher, is suitable for scenarios with strict pressure requirements such as high - pressure hydraulic systems, oil gas transportation, high - pressure test equipment.

2. Reliable Sealing:The precise cooperation between the ball the valve seat, as well as high - quality sealing materials, ensure the good sealing performance of the valve under high pressure, reduce the risk of leakage, improve the stability safety of the system.

3. Convenient Operation:The lightweight handle design results in a small operating torque, allowing the valve to be easily opened closed even under high - pressure conditions. It can be manually operated easily integrated into an automated control system.

4. Easy Installation:The panel - mounted method only requires opening holes on the equipment panel fixing it with matching installation nuts bolts, saving space facilitating centralized control maintenance.

5. Long Service Life:High - quality materials precise manufacturing processes endow it with good wear resistance corrosion resistance, enabling it to operate stably for a long time in harsh environments reducing maintenance costs replacement frequencies.

Application Fields:

1. Oil Gas:In the exploration, transportation, processing sectors, it is used for the cut - off control of high - pressure gases liquids, such as wellhead devices, gas pipelines, refineries.

2. Chemical Industry:Suitable for the pipeline control of various corrosive, flammable, explosive media, such as the feeding discharging of reaction kettles high - pressure synthesis processes.

3. Hydraulic Systems:Widely used in the hydraulic systems of construction machinery, metallurgical equipment, aerospace, other fields to control the flow cut - off of oil, ensuring the normal operation of equipment.

4. Energy Power:Used in the cooling systems steam pipelines of nuclear power plants thermal power plants to ensure the safe transportation control of high - pressure media.

5. Scientific Research Testing:In high - pressure test equipment laboratory instruments, it is used to precisely control high - pressure fluids to meet experimental testing requirements.

Main Parameters:

1. Nominal Pressure:The common range is 10MPa - 100MPa (1450psi - 14500psi), there are also products with higher pressure ratings to meet different high - pressure working conditions.

2. Nominal Diameter:Generally ranging DN6 (1/4 inch) to DN100 (4 inches), the appropriate specifications can be selected according to the flow requirements.

3. Applicable Temperature:It depends on the valve body sealing materials. PTFE seals are generally suitable for - 20℃ - 200℃, metal seals can withstand higher temperatures, up to 500℃ even higher.

4. Valve Body Material:Stainless steel (such as 304, 316) alloy steel are mostly used to ensure strength corrosion resistance; for special working conditions, Hastelloy, Monel alloy, etc. can be selected.

5. Connection Method:In addition to panel mounting, common connection methods at the inlet outlet ends include threaded connections (such as NPT, BSPT) welded connections (butt - welding, socket - welding), which are convenient for connection to the pipeline system.

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!