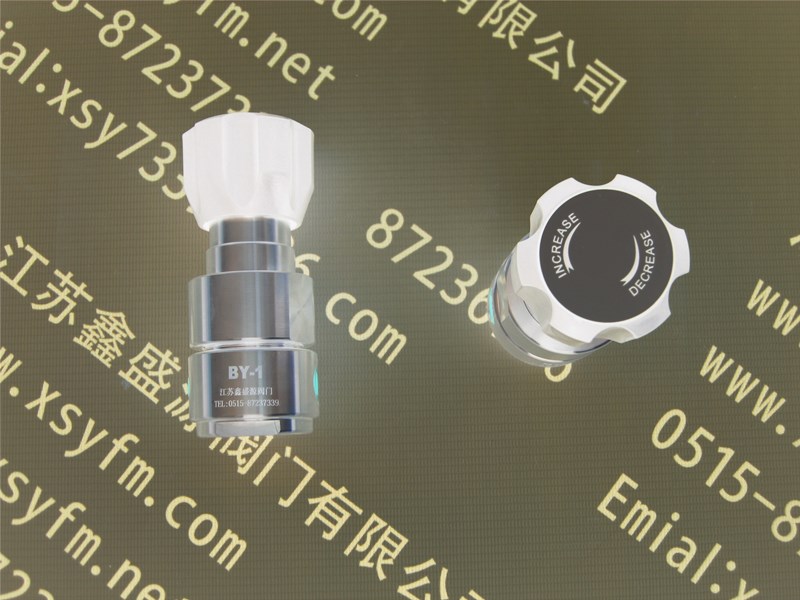

BY-1减压阀简介:

BY-1减压阀是通过调节,将进口压力减至某一需要的出口压力,并依靠介质本身的能量,使出口压力自动保持稳定的阀门。从流体力学的观点看,减压阀是一个局部阻力可以变化的节流元件,即通过改变节流面积,使流速及流体的动能改变,造成不同的压力损失,从而达到减压的目的。然后依靠控制与调节系统的调节,使阀后压力的波动与弹簧力相平衡,使阀后压力在一定的误差范围内保持恒定。

BY-1减压阀调压步骤:

1、关闭减压阀前的闸阀,开启减压阀后的闸阀,制造下游低压环境;

2、将调节螺钉按逆时针旋转至上限位置(相对下限出口压力),然后关闭减压阀后闸阀;

3、慢慢开启减压阀前的闸阀至全开;

4、顺时针慢慢旋转调节螺钉,将出口压力调至所需要的压力(以阀后表压为准);调整好后,将锁紧螺母锁紧,打开减压阀后闸阀;

5、如在调整时出口压力高于设定压力,须从一步开始重新调整,即只能从低压向高压调。

BY-1减压阀主要作用:

BY-1减压阀减压阀的作用原理是靠阀内流道对水流的局部阻力降低水压,水压降的范围由连接阀瓣的薄膜或活塞两侧的进出口水压差自动调节。

定比减压原理是利用阀体中浮动活塞的水压比控制,进出口端减压比与进出口侧活塞面积比成反比。这种减压阀工作平稳无振动;阀体内无弹簧,故无弹簧锈蚀、金属疲劳失效之虑;密封性能良好不渗漏,因而既减动压(水流动时)又减静压(流量为0时);特别是在减压的同时不影响水流量。

水流通过减压阀虽有很大的水头损失,但由于减少了水的浪费并使系统流量分布合理、改善了系统布局与工况,因此总体上讲仍是节能的。

介质为蒸汽的场合,宜选用先导活塞式减压阀或先导波纹管式减压阀。

为了操作、调整和维修的方便,减压阀一般应安装在水平管道上。

减压阀

减压阀是一种自动降低管路工作压力的专门装置 。它能通过调节,将阀前管路较高的介质压力减少并稳定至阀后管路所需的水平 。其核心作用是在进口压力波动和出口流量变化的情况下,将出口压力维持在一个设定的范围内,以保护下游设备并确保系统稳定运行 。

减压阀工作原理

减压阀的基本原理是通过控制阀体内启闭件(如阀瓣)的开度来调节介质的流量,利用介质的能量和压力反馈,使出口压力保持稳定 。

· 直动式减压阀:直接利用出口压力变化与调压弹簧的力平衡关系来控制启闭件。顺时针旋转调节旋钮压缩弹簧,会使出口压力升高;反之则降低 。这类阀门结构简单,在流量变化时,出口压力可能波动较大。

· 减压阀先导式减压阀:当输出压力较高或通径较大时,会采用先导式结构。它使用一个小型直动式减压阀(先导阀)来感知和控制主阀,提高了对阀芯控制的灵敏度和稳压精度 。适用于大口径、高精度或远距离控制的场合 。

· 减压阀定值器:这是一种高精度的减压阀,主要用于压力定值。它利用了输出压力的反馈和喷嘴挡板的放大作用,因此稳压精度非常高,输出压力波动通常不大于输出压力的1% 。

减压阀主要类型与特点

减压阀根据结构、介质和应用有不同的分类:

分类方式 类型 主要特点/适用场景

结构形式 薄膜式/弹簧薄膜式 动作平稳,适用于中低压、中小口径的空气、水介质 。薄膜型高灵敏度减压阀通过加大膜片工作面积,对下游压力变化传感特别明显,稳压功能强 。

活塞式 耐脏耐水垢,性能稳定。

波纹管式 适用于低压、中小口径的蒸汽介质 。

工作原理 直动式 结构简单,直接利用弹簧和膜片调压 。

先导式 调压精度高,适用于高压力、大通径场合 。

阀座数目 单座式、双座式 结构不同,适用不同压差和密封要求 。

适用介质 气体减压阀 用于压缩空气、氮气、氧气、天然气等 。需注意气体净化,除去机械杂质和液体 。

水用减压阀 用于高层建筑、城市给水管网等水系统,保持各用水点获得适当服务水压和流量,具有节水作用 。

减压阀主要技术参数

选型和使用时需关注以下关键参数 :

· 公称压力 (PN):阀门承载压力的能力,常见有1.0MPa、1.6MPa、2.5MPa等。

· 调压范围:减压阀输出压力P2的可调范围。

· 压力特性:指流量一定时,因输入压力波动而引起输出压力波动的特性。输出压力波动越小,特性越好。

· 流量特性:指输入压力一定时,输出压力随输出流量变化而变化的特性。输出压力变化越小越好。

· 适用介质与温度:根据阀门材质和密封,适用于水、空气、天然气及其他弱腐蚀性无杂质气体等,适用温度常见为0℃~80℃。

选型与应用要点

· 减压阀选型:需考虑弹簧压力级别、进口压力、出口压力设定值、所需流量(质量或体积流量)、介质类型和温度等因素 。

· 减压阀安装与维护:

· 安装前需对管道进行试压和吹扫,确保密封与清洁 。

· 为保持性能,通过减压阀的介质(尤其是气体)必须事先净化,去除机械杂质和液体 。气体管道上必须安装气体滤清器并定期清洗、更换 。

· 减压阀一般水平垂直安装在管道上 。

Complete English Translation

Product Overview of Pressure Reducing Valve

A pressure reducing valve is an automatic device designed to reduce the working pressure in a pipeline . It can lower the higher upstream pressure to the required downstream level maintain stability . Its core function is to maintain the outlet pressure within a set range despite fluctuations in inlet pressure outlet flow, thereby protecting downstream equipment ensuring system stability .

Working Principle

The basic principle involves regulating the flow rate of the medium by controlling the opening of the closure member (e.g., valve flap) inside the valve body, utilizing the energy of the medium pressure feedback to maintain a stable outlet pressure .

· Direct-Acting Reducing Valve: This type directly uses the force balance between the outlet pressure change the pressure regulating spring to control the closure member. Turning the adjusting knob clockwise compresses the spring, increasing the outlet pressure, vice versa . It has a simple structure, but the outlet pressure may fluctuate more significantly with flow changes.

· Pilot-Operated Reducing Valve: For higher output pressures larger diameters, a pilot-operated structure is used. It employs a small direct-acting valve (the pilot valve) to sense control the main valve, improving control sensitivity pressure stabilization accuracy . It is suitable for large diameters, high precision, remote control applications .

· Precision Regulator: This is a high-precision pressure reducing valve used primarily for pressure setting. It utilizes output pressure feedback a nozzle-flapper amplification mechanism, resulting in very high pressure stabilization accuracy, with output pressure fluctuation generally exceeding 1% of the maximum output pressure .

Main Types Features

Pressure reducing valves can be classified based on structure, medium, application:

Basis of Classification Type Key Characteristics / Applications

Structure Diaphragm Type / Spring-loaded Diaphragm Type Stable operation, suitable for medium-low pressure, small-medium diameter air water services . High-sensitivity diaphragm valves feature a greatly increased diaphragm working area, making them particularly sensitive to downstream pressure changes enhancing pressure stabilization .

Piston Type Resistant to dirt scale, reliable performance .

Bellows Type Suitable for low-pressure, small-medium diameter steam services .

Operating Principle Direct-Acting Simple structure, direct pressure regulation via spring diaphragm .

Pilot-Operated High pressure regulation accuracy, suitable for high-pressure, large-diameter applications .

Number of Valve Seats Single Seat, Double Seat Different structures for different pressure differences sealing requirements .

Applicable Medium Gas Pressure Reducing Valve Used for compressed air, nitrogen, oxygen, natural gas, etc. . The gas must be purified to remove mechanical impurities liquids .

Water Pressure Reducing Valve Used in water systems like high-rise buildings municipal water supply networks with high pressure to ensure appropriate service pressure flow at usage points, contributing to water conservation .

Main Technical Parameters

Key parameters for selection use include :

· Nominal Pressure (PN): The pressure-bearing capacity of the valve. Common ratings are 1.0MPa, 1.6MPa, 2.5MPa, etc.

· Pressure Regulation Range: The adjustable range of the valve's outlet pressure (P2).

· Pressure Characteristic: Refers to the variation in outlet pressure caused by inlet pressure fluctuations when the flow rate is constant. Smaller outlet pressure variation indicates better performance.

· Flow Characteristic: Refers to the variation in outlet pressure with changes in output flow when the inlet pressure is constant. Smaller changes in outlet pressure are better.

· Applicable Medium Temperature: Depending on valve material seals, suitable for water, air, natural gas, other weak corrosive, impurity-free gases, etc. Common operating temperature is 0°C to 80°C.

Selection Application Guide

· Selection: Factors to consider include the spring pressure rating, inlet pressure, desired outlet pressure setting, required flow rate (mass volumetric), medium type, temperature .

· Installation & Maintenance:

· Pipes should be pressure-tested purged before installation to ensure tightness cleanliness .

· To maintain performance, the medium passing through the valve (especially gases) must be purified beforehand to remove mechanical impurities liquids . A gas filter must be installed on gas pipelines regularly cleaned replaced .

· The pressure reducing valve is generally installed horizontally vertically in the pipeline .

本站部分内容图片来源于互联网,如有侵权请及时联系管理员删除,谢谢!